West Control Solutions Pro-EC44 User Manual

Page 60

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

Pro-EC44 Product Manual - 59540-1 October 2013

Page 53

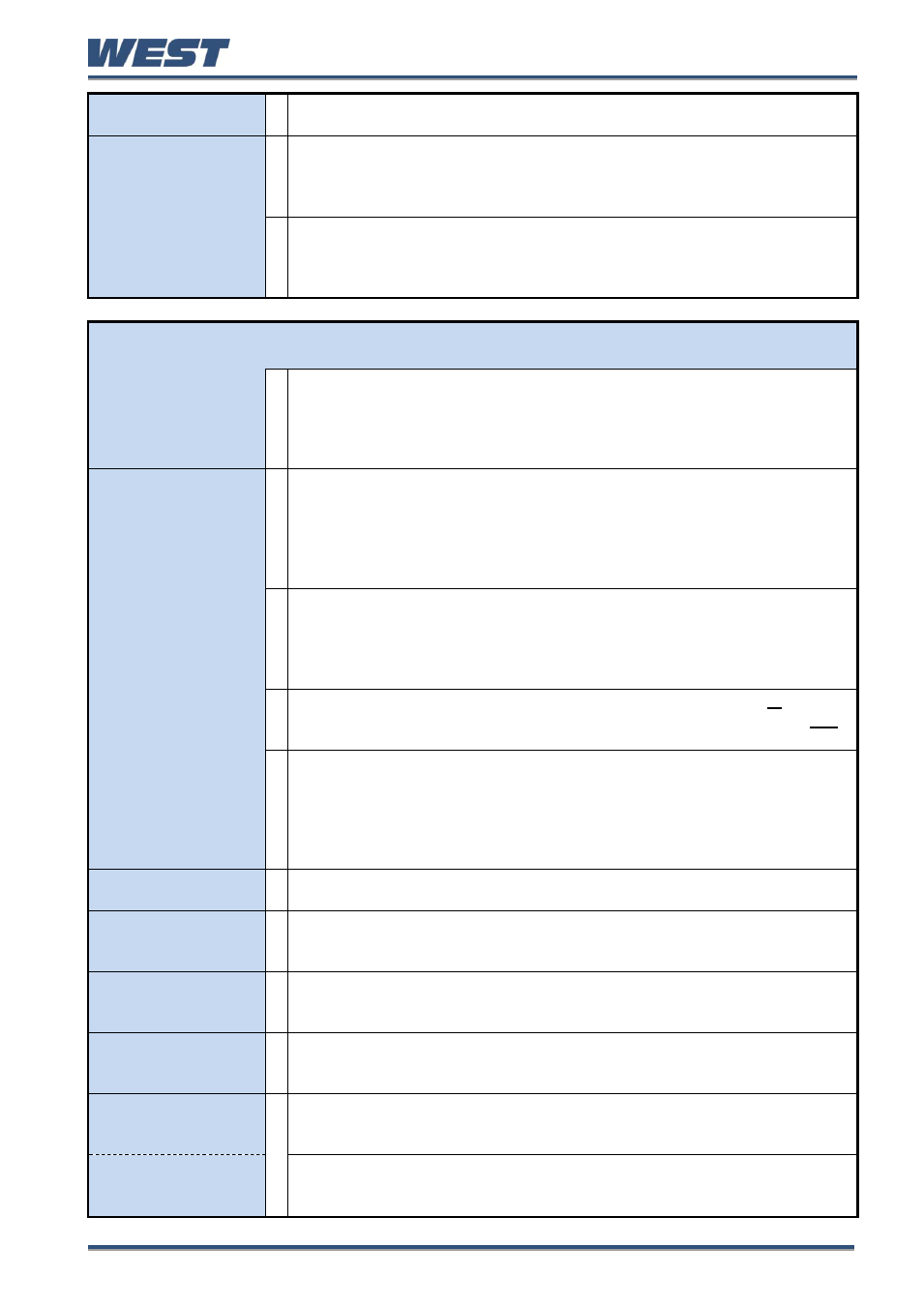

Select Active

Setpoint

Select if the main or alternate setpoint is to be the current

“active” setpoint

for this loop.

Main Setpoint Offset

An offset that can be added to the main setpoint (+ve values) or subtracted

from it (-ve values) when the instrument is a comms slave in a multi-zone

application. This changes the effective setpoint used for control.

Caution:

It should be set to zero if an offset is not required.

Alternate Setpoint

Offset

An offset that can be added to the alternate setpoint (+ve values) or

subtracted from it (-ve values) when the instrument is a comms slave in a

multi-zone application. This changes the effective setpoint used for control.

Caution:

It should be set to zero if an offset is not required.

Control Loop 2 - Sub-menu to setup Control Loop 1. Press D + R to return to Input Menu

These settings apply to the slave loop if the controller has been setup for cascade control.

Control Select

Select from Control Standard or Control VMD (TPSC).

Use Control VMD to directly drive the windings of a motorised valve. This

uses a 3-point stepping

algorithm giving “open” and “close” outputs.

Use Standard for all other applications (including solenoid valves or

modulating valves with positioning circuitry requiring mA or VDC signals).

Control

Enable/Disable

Used to temporarily disable the control outputs. Select control Enabled

(normal) or Disabled

– when disabled, control output(s) for this loop are

turned off (unless manual mode has been selected) and the setpoint value

is replaced by “OFF”.

Caution:

The instrument is not able to control the process when

control is disabled and the Output Power Limits are ignored.

Auto/Manual Control

Selection

Switches the control loop between Automatic and Manual Control.

Caution:

Manual mode overrides the automatic control loop. It also

ignores any output power limits, valve open/close limits and the

control enable/disable setting. The operator is responsible for

maintaining the process within safe limits.

Control Type

Select Single Control for primary control only (e.g. heating only or cooling

only) or Dual for primary and secondary control outputs (e.g. heating and

cooling) - Dual is not possible with Ratio or VMD Control.

Primary Control

Action

Set the primary control output for Reverse or Direct Action.

Reverse action applies additional primary power as the process falls

further below setpoint (e.g. heating applications).

Direct action applies additional primary power as the process rises higher

above setpoint (e.g. cooling applications).

In dual control, secondary output action is opposite to primary action.

Control Status

A “read-only” diagnostic status display of the current loop 2 process

variable and effective setpoint values to assist with manual tuning.

Power Output Levels

A “read-only” diagnostic status display of the current loop 2 primary and

secondary % output power levels to assist with manual tuning

– Not shown

with VMD Control. Does not apply if control is disabled or in manual mode.

Gain Schedule PID

Set in use

A “read-only” diagnostic status display showing the PID set in use. The set

use may vary based on the current setpoint or process variable value.

–

Only shown if Gain Scheduling is in use.

PID Set Selection

Choose to use one of five PID Sets; or choose Gain Schedule on SP or

PV.

– This selects a fixed PID set to be “Active”; or automatically switch

sets based changes in SP or PV values.

Set n

– Primary Pb

The primary proportional band for PID Set n (n = up to 5). Set as On-Off

control, or a proportional band from 1 to 9999 display units

– Only the

set(s) in use are shown.

Set n

– Secondary Pb

The secondary proportional band for PID Set n (n = up to 5) if dual control

is used. Set as On-Off control, or a proportional band from 1 to 9999

display units

– Only the set(s) in use are shown.