Profile setup via modbus – West Control Solutions Pro-EC44 User Manual

Page 194

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

Pro-EC44 Product Manual - 59540-1 October 2013

Page 187

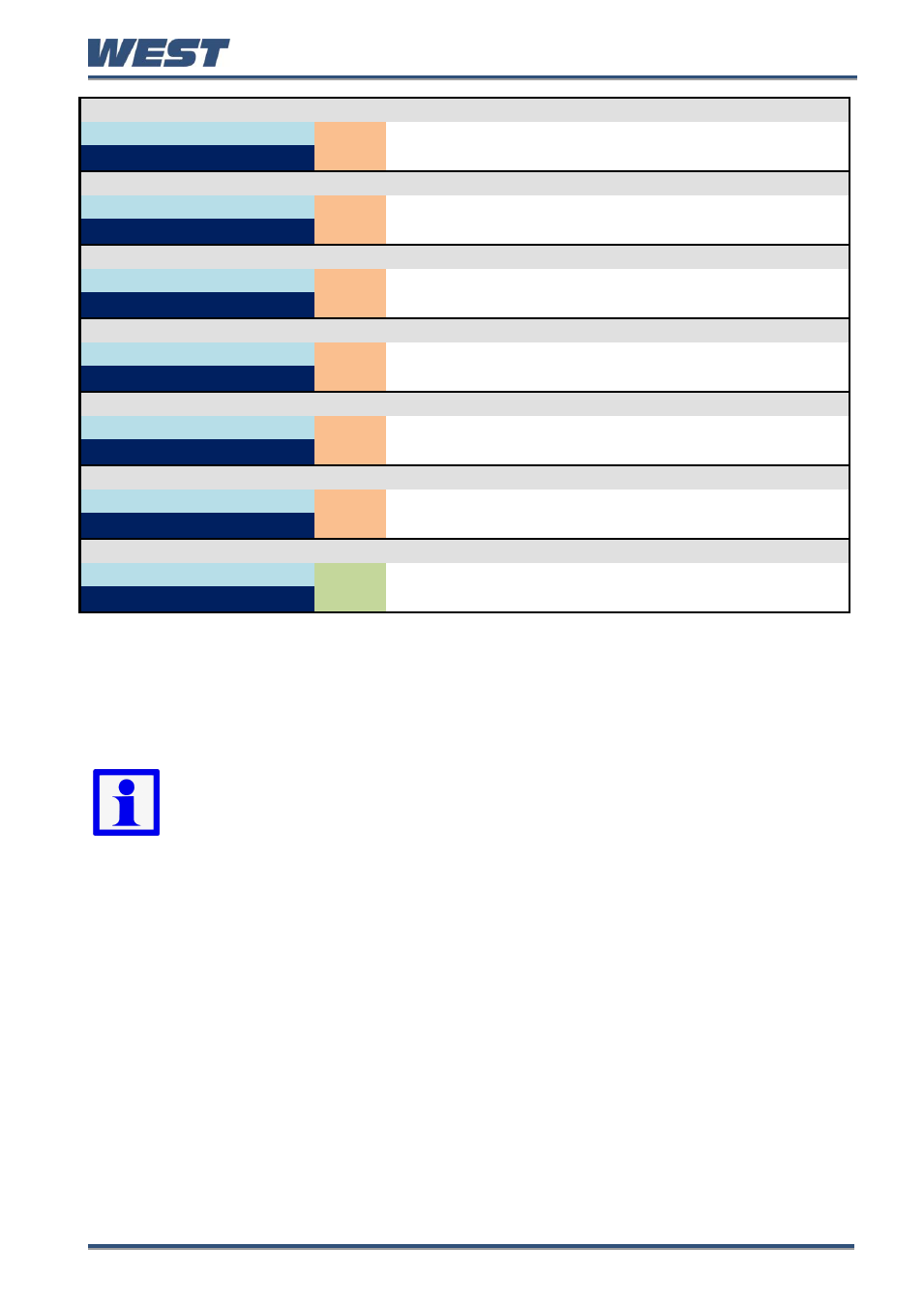

Current Profile Running Time

Current Profile Running Time

Dec

8235

24619 49238

RO

The elapsed time of the current running profile in seconds since

it began running.

Hex

202B

602B

C056

Current Profile Remaining Time

Current Profile Remaining Time

Dec

8236

24620 49240

RO

The remaining time for the current running profile before

reaching its end segment, in seconds

Hex

202C

602C

C058

Current Segment Running Time

Current Segment Running Time

Dec

8237

24621 49242

RO

The elapsed time of the current profile segment in seconds

Hex

202D

602D

C05A

Current Segment Remaining Time

Current Segment Remaining Time

Dec

8238

24622 49244

RO

The remaining time for the current profile segment in seconds

Hex

202E

602E

C05C

Total Hold Time

Total Hold Time

Dec

8239

24623 49246

RO

Total (accumulated) time the current profile has been held in

seconds

Hex

202F

602F

C05E

Current Segment Loops Run

Number of Current Segment Loop-backs

Dec

8240

24624 49248

RO

The number of times the current looping segment has looped

back

Hex

2030

6030

C060

Profile Setup

Profile Setup via Modbus

Dec

8198

24582 49164

RW

Note: Refer to the Profile Setup Over Modbus information

below for setting up profiles via comms

Hex

2006

6006

C00C

Profile Setup via Modbus

The information in this section is intended for advanced users writing their own software

code. Most users will create or edit profiles using the instrument keypad, or using the the PC

software (available from your supplier). Either method allows quick and easy editing of

profiles.

Advanced users can setup or edit profiles by writing to the Profile Configuration parameter at

address 8198 (0x2006). This can only be accessed by using Modbus function code 23

(0x17). The instrument replies with a status message.

When creating a new profile the steps below must be followed exactly, either to create a

profile at the next available position, or at the position you specify.

Each message in the sequence includes a 2 byte Command Code that tells the instrument

the purpose of the message, and therefore the meaning of the data contained in it.

Instruction Sequence to create a profile at the next available position

1. Create a profile by writing the profile header data using the Command Code value CP

(0x43, 0x50). This starts the profile creation process by reserving a profile memory slot.

The profile number is returned by the instrument in the Edit Response Message.

Note: There is a global block on profile creation or editing via Modbus while a

profile is running. An attempt to do so returns the error code 0x15.

The only profile related commands allowed while a profile runs are the Profile

Control & Status Parameters in the previous section.