Metrohm 796 Titroprocessor User Manual

Page 46

3.2 Configuration of sample changers

796 Titroprocessor, Instructions for use

40

40

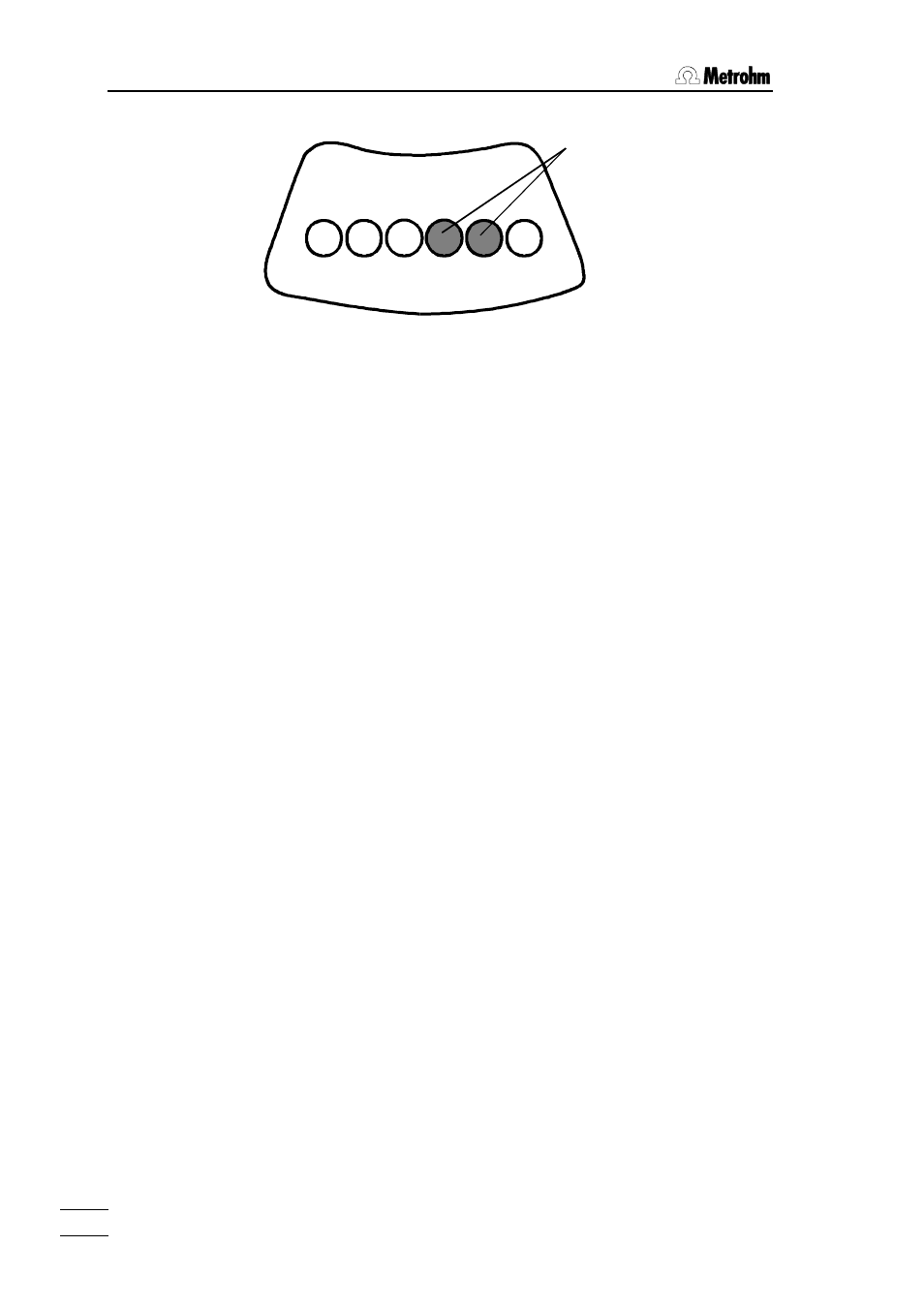

Magnets inserted

In this

example the code is:

000110

In order to allocate a certain sample rack to a particular application it is

possible to define particular properties or characteristics for up to 16 racks.

This makes sense when an application requires a particular size of vessel,

size of sample series or a particular procedure in order for the method to be

carried out.

The following characteristics can be defined for each rack:

Rack name

The

rack name is used for the unambiguous

identification of a rack. The command 'Changer' in the

method run can be used to stipulate the use of a

particular rack. The automatic rack recognition ensures

that the use of an incorrect sample rack is recognized

and that the operator is informed of this.

Beakers

The number of beaker positions is obtained from the rack

table. It does not need to be entered.

Special positions

For the lift stations of a changer tower particular „stopping points“, i.e.

predefined lift positions can be laid down:

Work

The

work position is used for fixing the position of the

titrating head (lift), in which e.g. a titration can be carried

out. Depending on the height of the sample beaker the

ideal setting can always be selected for each sample

rack. In manual operation this work position can be

moved to directly by means of the

Shift

The

shift position is used to fix the position of the

titrating head (lift) in which the sample rack can be

rotated. If the lift is not at or is above the shift position

then the sample rack cannot be rotated. This is a safety

measure as damage to the sensors caused by rotary

movement of the rack is practically ruled out. A

precondition is the correct setting of the shift position. In

manual operation this shift position can be moved to

directly with the

Rinse

The

rinsing position is used to fix the position of the

titrating head (lift) at which the sensors can be rinsed at

the titrating head.