Cause & remedy, Drive plc, Appendix – Lenze Global Drive PLC Developer Studio User Manual

Page 92: 4 cause & remedy

8.5

System error messages

Drive PLC

Appendix

8−12

L

DrivePLC DE 6.0

8.5.4

Cause & remedy

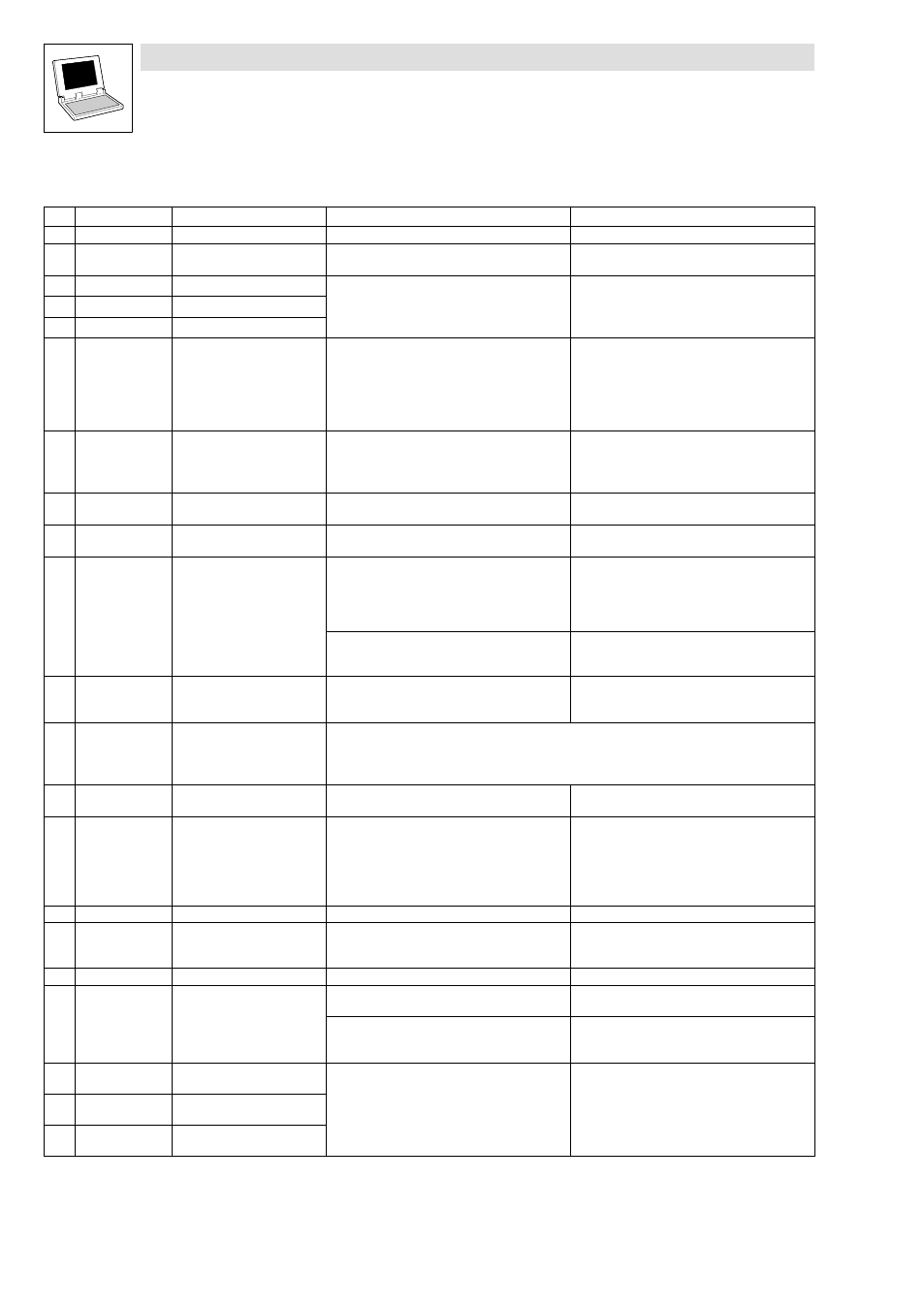

No.

Display

Meaning

Cause

Remedy

−−−

−−−

No error

−

−

061

CE0

Communication error

AIF module

óBasic unit

Interference during transfer of control commands

via automation interface (AIF)

Plug in automation module firmly, bolt down, if

necessary

062

CE1

CAN1_IN communication error

CANx_IN receives faulty data or communication

interrupted

·

Check wiring/cable

·

Check transmitter

·

If possible, increase monitoring time under

C0357/x

063

CE2

CAN2_IN communication error

064

CE3

CAN3_IN communication error

065

CE4

CAN BUS−OFF status

(too many faulty telegrams

received)

PLC has received too many faulty telegrams sent

via system bus and has disconnected itself from

the bus

·

Check wiring/cable

·

Check bus termination (if any)

·

Check screen contact of the cables

·

Check PE connection

·

Check bus load

·

Reduce baud rate (observe cable length)

066

CE5

CAN time−out

(gateway function)

For remote parameterisation via system bus

(C0370):

·

Slave does not respond

·

Communication monitoring time exceeded

·

Check system bus wiring/cable

·

Check system bus configuration

070

U15

Undervoltage of internal 15 V

voltage supply

Check voltage supply for Drive PLC

071

CCR

Internal error

The program sequence of the processor was

interfered

·

Shield control and motor cables as necessary

·

Check PE wiring and PE connections

072

PR1

Check sum error

in parameter set 1

CAUTION:

Lenze setting is loaded

automatically!

·

Error while loading a parameter set

·

Interruption of parameter set transfer via

keypad (e.g. by disconnection of the keypad)

·

Set the desired parameters and save them

under C0003

·

For PR0 the supply voltage must be switched

off additionally

·

Check use of pointers

The saved parameters do not match the loaded

software version

Before an error can be acknowledged, the

parameter set must be manually saved under

C0003

074

PEr

Program error

Error detected in program

·

Check use of pointers

·

Send controller with parameter set and PLC

program (on diskette) to Lenze

075

PR0

General error in parameter sets

CAUTION:

Lenze setting is loaded

automatically!

See Cause & Remedy, no. 072 (PR1)

076

PR5

Error while saving parameters

Error while saving parameters in the fail−safe

memory area

Contact Lenze

079

PI

Error during

parameter initialisation

·

Error detected during parameter set transfer

between two controllers

·

Parameter set does not match the PLC or

controller (e.g. data transfer from a

high−performance controller to a

lower−performance controller)

·

Correct the parameter set

·

Check code initialisation values

080

PR6

Too many user codes

Reduce the number of user codes

x09

EEr

External monitoring activated

via DCTRL

A digital signal assigned to the TRIP−SET function

has been activated (system block DCTRL is

integrated as of software version V8.0)

·

Check external encoder

·

Deactivate monitoring (C0581 = 3)

105

H05

Internal error (memory)

Contact Lenze

108

H08

Extension board error

Extension board not connected correctly

·

Connect extension board properly

·

Check connection plug EB

óPLC

Extension board is not supported by PLC program

·

Adapt PLC program to extension board

·

Use extension board which is supported by PLC

program.

122

CE11

Communication error

FIF−CAN1_IN

FIF−CANx_IN receives faulty data or

communication interrupted

·

Check wiring/cable

·

Check transmitter

·

If possible, increase monitoring time under

C2457/x

123

CE12

Communication error

FIF−CAN2_IN

124

CE13

Communication error

FIF−CAN3_IN