IAI America CON-PGA User Manual

Page 197

7. Operation of MEC Related Controllers

189

4) Deceleration [G] --- Set the deceleration (G) at which the actuator stops.

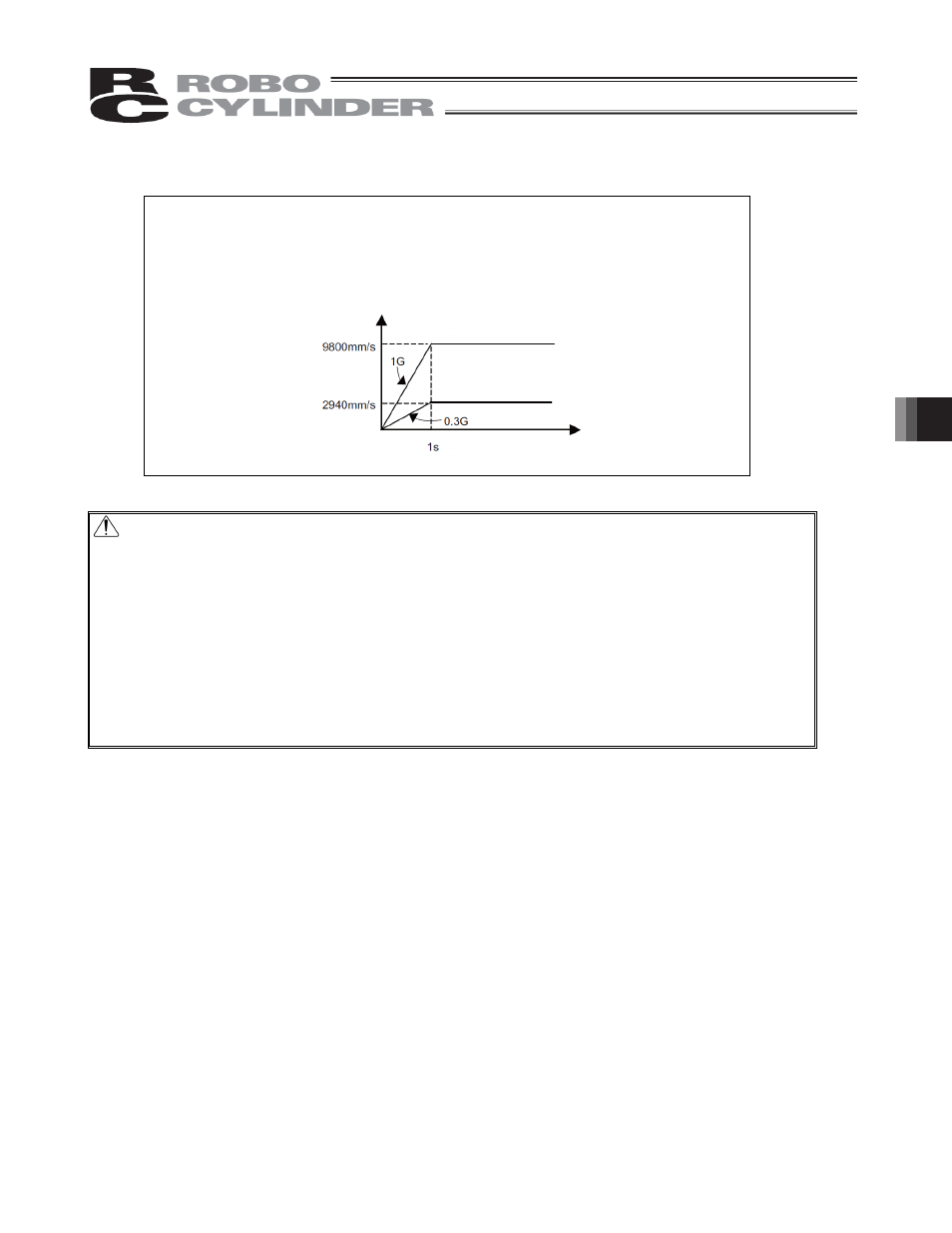

(Reference) Acceleration is explained. The same concept applies to deceleration.

1 G = 9800 mm/s

2

: Acceleration at which the actuator can accelerate to

up to 9800 mm/s per second

0.3 G: Acceleration at which the actuator can accelerate to up to 9800

mm/s

u

0.3 = 2940 mm/s

Caution: Setting the acceleration/deceleration

(1) Make sure the acceleration/deceleration you set does not exceed the rated

acceleration/deceleration stated in the catalog or this operation manual. If the rated

acceleration/deceleration is exceeded, the life of the actuator may drop significantly.

(2) If the actuator or work part receives impact or vibrates, lower the

acceleration/deceleration. If the actuator is used continuously in such condition, the life

of the actuator will drop significantly.

(3) If the transferable weight is significantly smaller than the rated payload capacity,

accelerations/decelerations greater than the rating may be set. You can shorten the

tact time this way, so contact IAI if you are interested. When contacting IAI, let us know

the weight, shape and installation method of the work part as well as installation

condition of the actuator (horizontal/vertical).

5) Push force [%]

--- Set the push torque (current-limiting value) to be used in push-motion operation as

a percent (%) value.

Increasing the current-limiting value increases the push force.

If “0” is set, positioning operation is performed.

For the relationship of push force and current-limiting value, refer to the catalog or

the operation manual."

6) Push band [mm] --- Set the travel during push-motion operation.

When push-motion operation is performed, the actuator moves at the speed and

rated torque set as part of positioning information, just like normal positioning, until

the remaining travel enters the range set here. Once the remaining travel enters

this range, the actuator moves to the position set in [1] while pushing the load.

The speed of push-motion operation is set in parameter No. 7. Do not use any

setting that causes this speed to be exceeded.

If the setting in [2] is less than the push speed, the actuator pushes the work part at

the set speed.

How the actuator operates as it pushes the work part toward the end point, start

point and intermediate point is illustrated below.

Speed

Time