IAI America ERC2 User Manual

Page 90

0

5. Explanation of Operating Functions

71

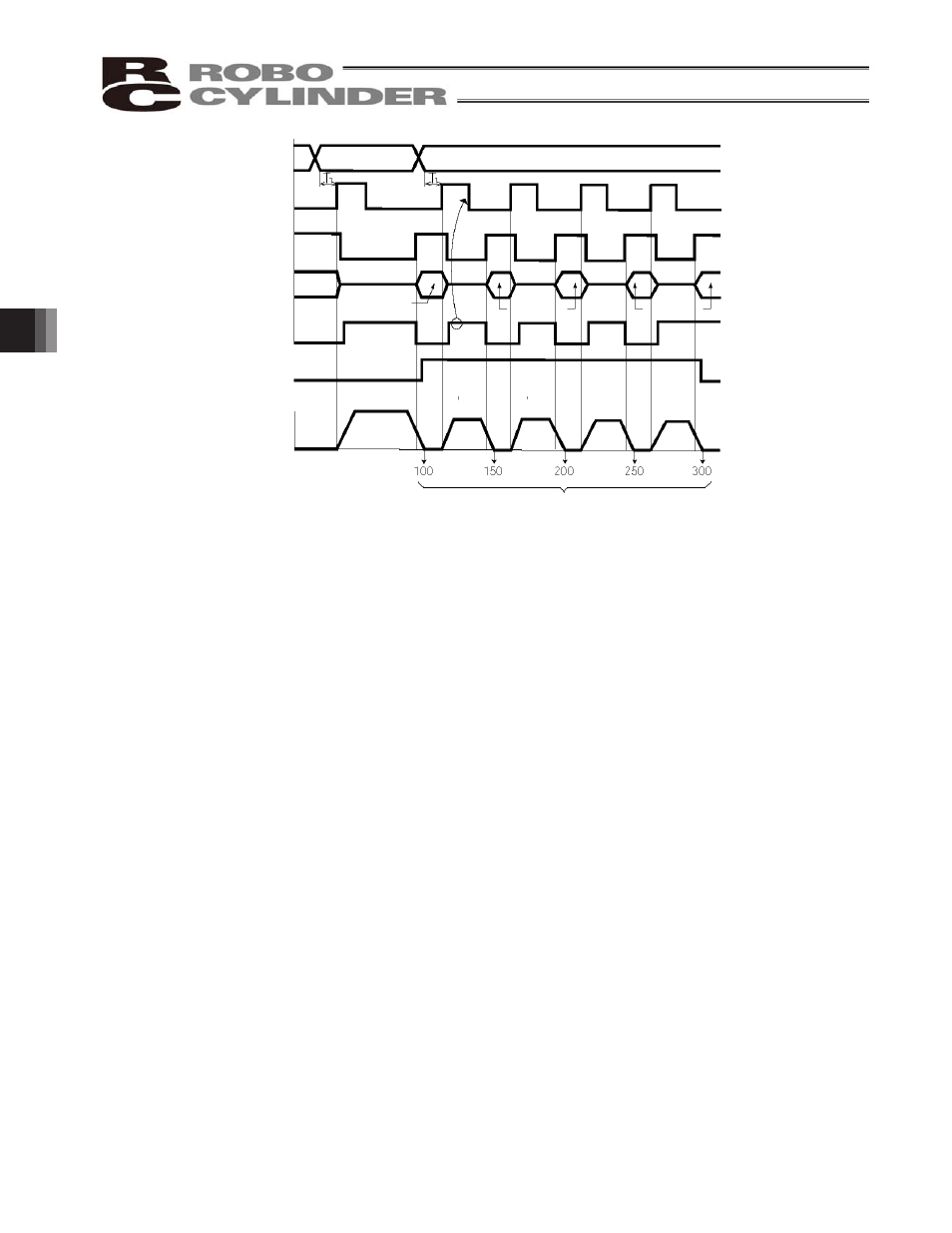

*T1: Set to T1 t 0 (ms) by considering the scan time of the host controller.

[Explanation of operation]

[1] Perform positioning operation to position 1 (100.00 mm).

[2] When the positioning to position 1 has completed, the position complete (PEND) bit turns “1.” The zone

(PZONE) signal bit also turns “1.”

Switch the position number from 1 to 2, and change the start (CSTR) bit to “1.”

[3] The moment the actuator starts moving, the position complete (PEND) bit changes from “1” to “0” and

the moving (MOVE) bit changes from “0” to “1.” After confirming that MOVE has turned “1,” change the

start (CSTR) bit to “0.”

[4] After the actuator has moved 50 mm, again the position complete (PEND) bit turns “1” and the moving

(MOVE) bit turns “0.” The PLC increments its movement count by 1.

Next, change the start (CSTR) bit to “1” for the second 50-mm movement.

[5] Repeat steps [3] and [4] hereafter.

The PLC checks the zone (PZONE) signal status upon completion of positioning. If the signal bit is “0,” the

PLC will determine that the position of the last work part has been reached.

If the count kept by the PLC does not match the zone signal status, signal timings may not be synchronized.

Command position

Start

(CSTR)

Position complete

(PEND)

Completed position

Moving (MOVE)

Zone signal

(PZONE)

Actuator movement

Speed

Position 1

Position 2

Position 1

Position 2

Position 2

[1]

[2]

[3]

[4]

[5]

Time

Distance from home