3 differences from air cylinder control – IAI America ERC2 User Manual

Page 21

1. Overview

3

1.3 Differences from Air Cylinder Control

This section explains the key differences between an air cylinder and this controller for users who are familiar

with air cylinders but have never used a motorized cylinder before.

Refer to the table below to perform appropriate controls.

Item

Air cylinder

This controller

Drive method

Driven by air pressure

based on electromagnetic

valve control.

Driven by a ball screw or timing belt using a pulse motor.

Target position

setting

Mechanical stopper

(including a shock absorber)

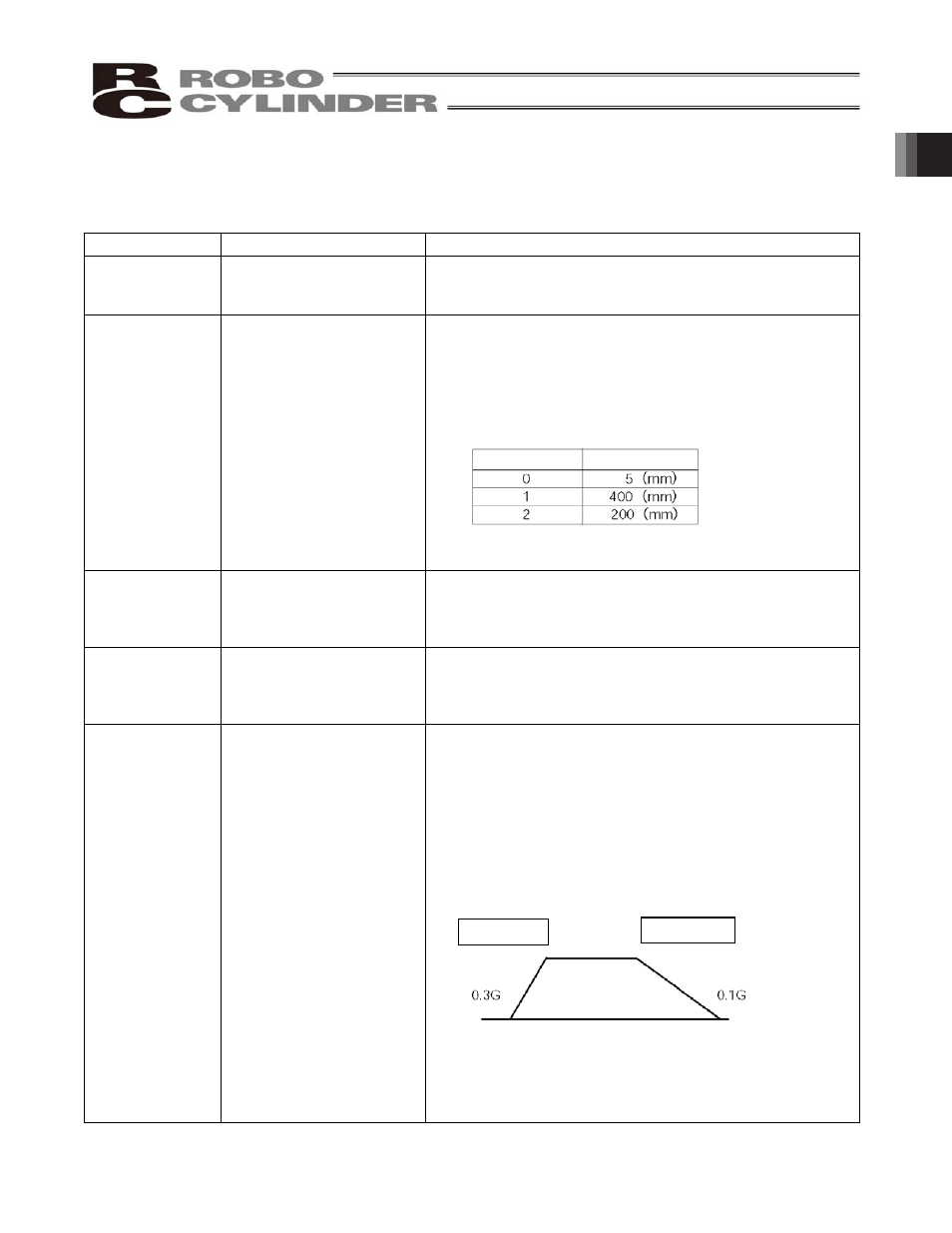

[1] Position number specification mode

Enter a coordinate in the [Position] field of the position table.

You can key in a desired coordinate using the number keys

on a PC (keyboard)/teaching pendant, or move the actuator

to a desired position and then write the coordinate to the

position table directly.

Example) Entries on a 400-mm actuator

[2] Numerical specification mode: Specify a desired value

directly.

Target position

detection

A reed switch or other

external detection sensor is

installed.

Whether or not the target position has been reached is

determined based on the internal coordinate information

received from the position detector (encoder).

Accordingly, no external detection sensor is required.

Speed setting

Adjusted using a speed

controller.

[1] Enter a feed speed in the [Speed] field of the position

table (in mm/sec).

Initially, the default speed has been set automatically.

[2] Specify a desired value directly.

Acceleration/

deceleration

setting

In accordance with the load,

air supply volume, and

speed

controller/electromagnetic

valve performance.

[1] Enter an acceleration or deceleration in the [Acceleration]

or [Deceleration] field of the position table (in units of 0.01

G).

Reference: 1 G = Gravitational acceleration that generates

when the actuator drops freely.

Initially, the default acceleration and deceleration have been

set automatically.

[2] Specify a desired value directly.

Since acceleration and deceleration can be set finely, you

can define a gradual deceleration/acceleration curves.

Larger acceleration/deceleration values set steeper curves,

while smaller acceleration/deceleration values set more

gradual curves.

Position No.

Position

Acceleration

Deceleration

Movement

start position

End position