4 internal check (slider type) – IAI America ERC2 User Manual

Page 117

0

8. Maintenance and Inspection

98

8.4 Internal Check (Slider Type)

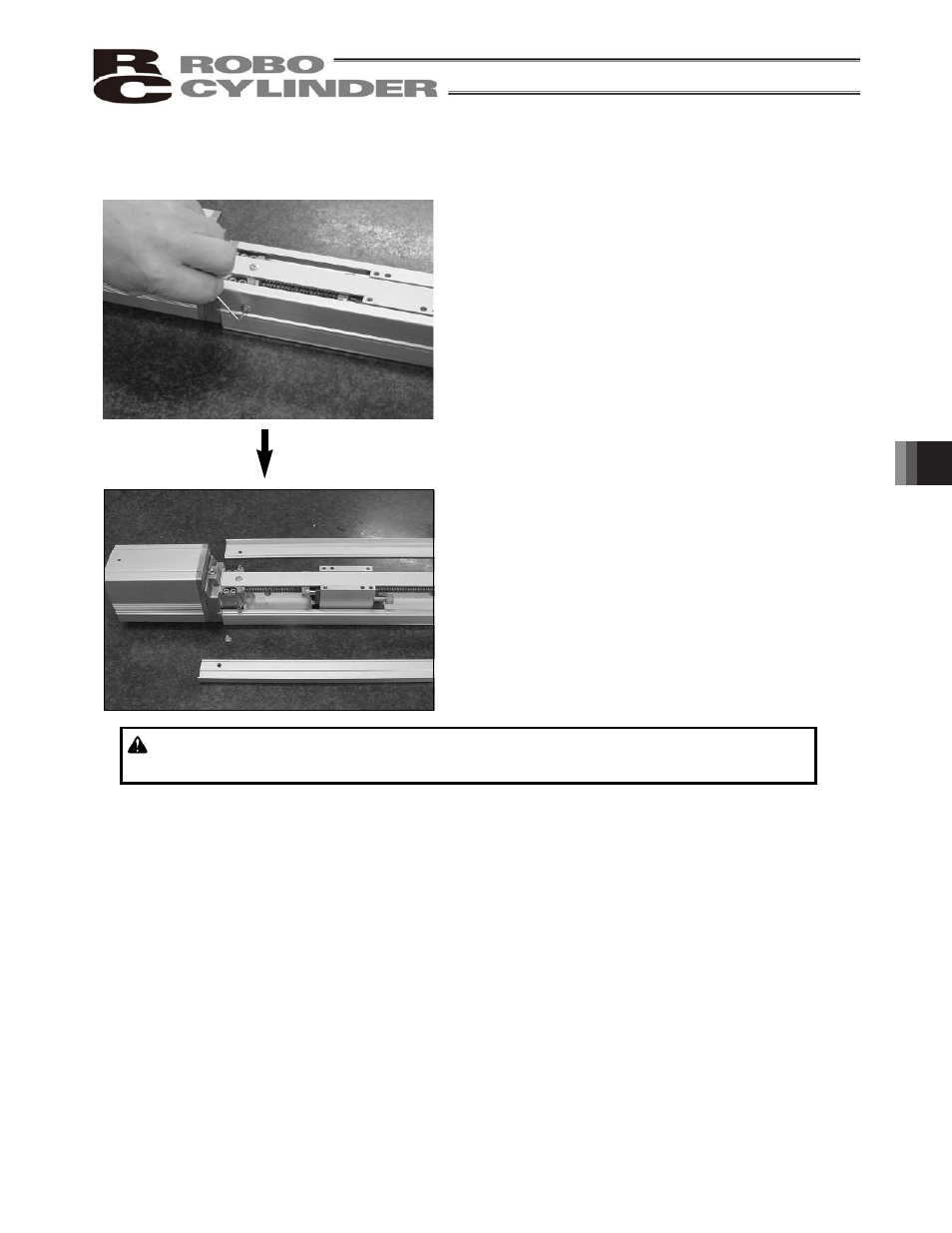

[1] With the SA6 and SA7, the screw cover and

side covers can be removed using a hex wrench

with 1.5 mm width across flats.

x

The front and rear brackets are supporting the

ball screw, so do not disassemble these

brackets.

x

Precision instrument is assembled into the

motor cover, so do not disassemble the motor

cover.

[2] Visually check the internal condition. Check for

intrusion of dust and other foreign object, and

also check the lubrication condition. Even when

the grease is brown, the sliding surface is

lubricated properly if the surface looks wet and

glowing.

Warning: The encoder phase is adjusted precisely to enable detection of rotation angle and

home signal. Never touch the encoder, since it may cause a breakdown.

[3] If the grease is contaminated with dust and not glowing, or if the grease has been consumed over a long

period of use, apply grease after cleaning the respective parts.

[4] When the inspection/maintenance is complete, install the side covers, stainless sheet and slider cover by

reversing the procedure in step [1] above. The tightening torque should be around the level applicable for

Phillips recessed screws.