Program steps – ACU-RITE MILLPWR 2 Axes User Manual

Page 91

PROGRAM STEPS

MILLPWR

®

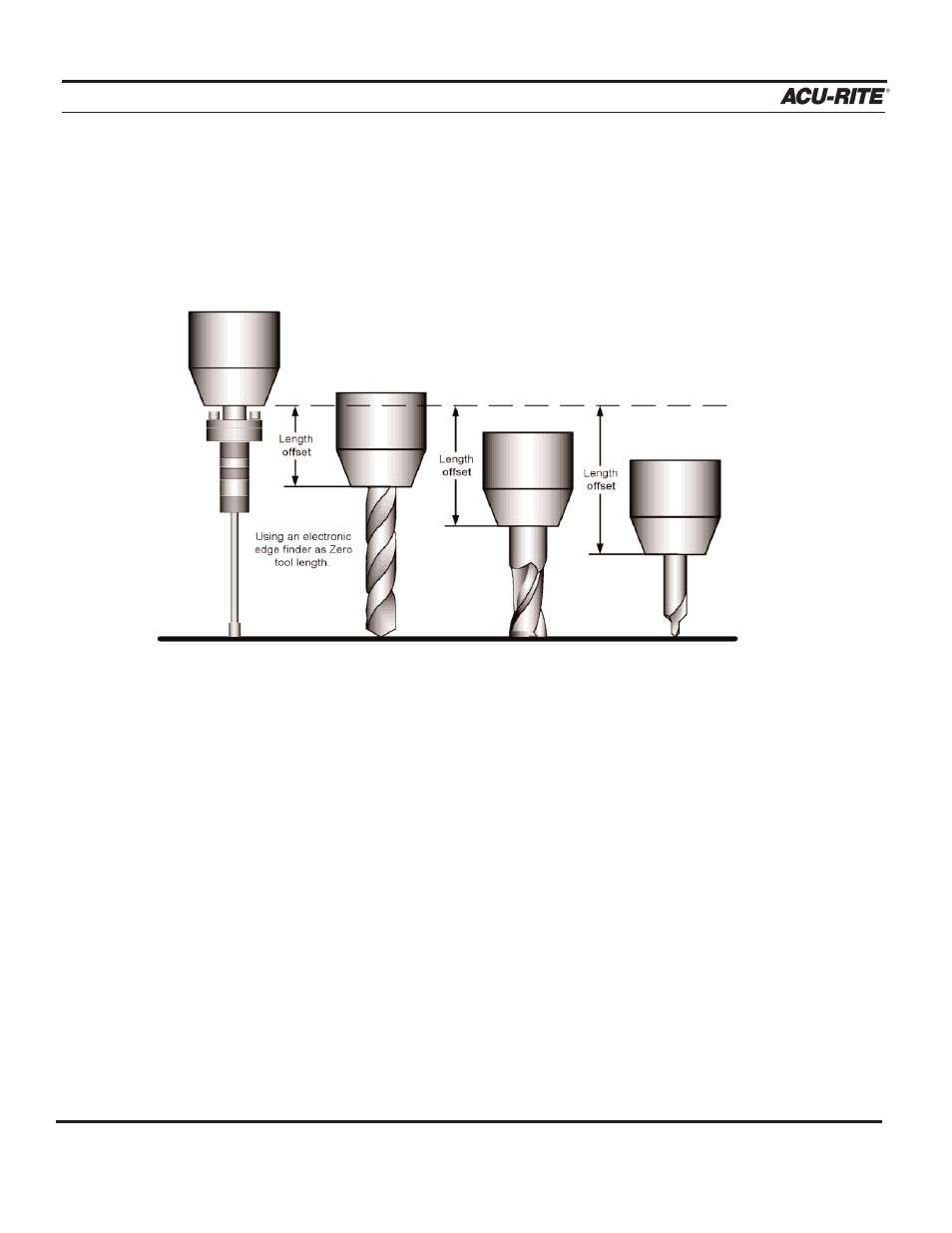

Programming a Tool Step with Repeatable Tool Length Offsets

If you begin setting the tool length offsets by setting Datum using an electronic edge finder

it must have a fixed and repeatable length. The current tool information cannot have a

length value. All of the tool length offsets in the program will be the difference in length

between the tool and the edge finder.

When defining tool length offsets in the Tool Step, touch each tool to the same surface and

press the

TEACH TOOL LENGTH

softkey to establish the tool length.

Once you have identified the tools you will be using, you can program the length offsets

into the tool steps.

Entering the first tool

Set the Z-axis Datum with a tool or standard using no tool length offset. In this example, the

first tool in the program is used to set datum zero. If you wish to use an electronic edge

finder or tool holder with a repeatable standard, then place it into the spindle instead, and

set datum. Then you find the tool length offset for tool 1 as well.

Operation Manual

5-2