Programming – ACU-RITE MILLPWR 2 Axes User Manual

Page 36

PROGRAMMING

MILLPWR

®

Operation Manual

3-7

Running a Program

There are a few things that may need to be done before running a program, such as skewing

the part and establishing datum.

Skewing a Part

Note: It is important to skew a part prior to establishing datum for accuracy.

Save time setting up a job by skewing the part. The skew function automatically compen-

sates for the angle offset of the part. If a part is not perfectly parallel with either the X- or

Y-axis, indicating it in is not necessary.

To skew a part, simply “touch off” on two or more points along one axis (either X or Y).

Use an electronic edge finder to skew the part, or use a mechanical indicator and teach

position—either way, it’s fast and easy.

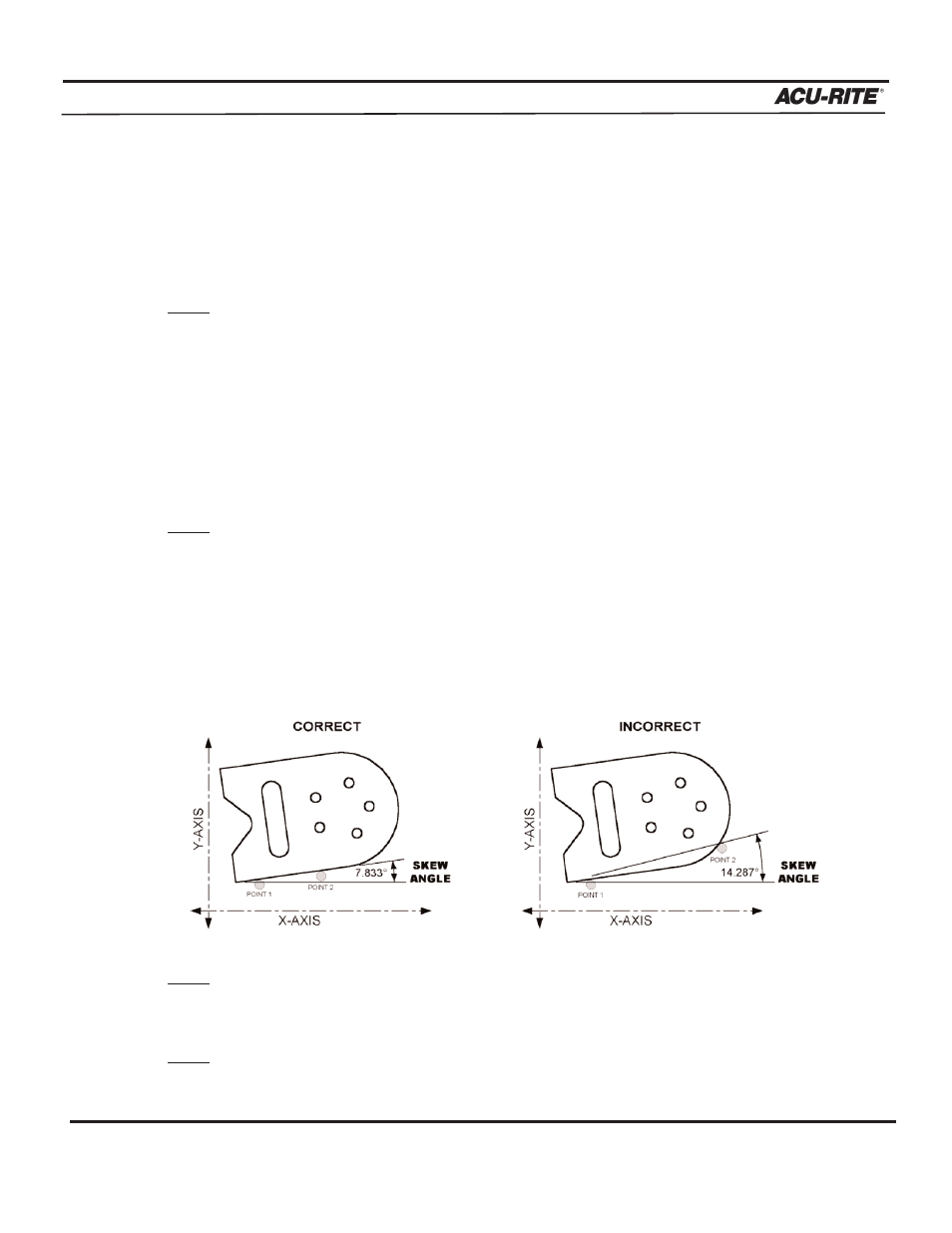

Note:

Choose a line to make parallel with the table’s X- or Y-axis—do not enter coor-

dinates along a curve, along two different lines, or along a line that is positioned

at a 45 degree angle.

MILLPWR

will calculate the skew angle based upon a

straight line between the points entered.

If you are working with a part that has a rough edge, it’s best to enter multiple points

along the straightest edge so that

MILLPWR

can more accurately compensate for the skew

angle.

Note: When two or more points are entered in the skew calculator

MILLPWR

will calcu-

late the angle and adjust the X and Y plane. Angles that are less than 45° are

adjusted down to the X-axis, and angles greater than 45° adjust up to the Y-axis.

Note: The skew feature does not not work with G-code programs. Remove any skew

angle prior to running a G-code program.