Setup – ACU-RITE MILLPWR 2 Axes User Manual

Page 178

SETUP

MILLPWR

®

Operation Manual

•

Place the selected tool in the spindle. A

MOVE TABLE

softkey is available to help you

move away from the workpiece if necessary. You can program a position move prior to

the tool step to automatically move off the part before changing the tool.

•

Press the

GO

key to confirm that you have installed the tool. The program will resume.

Changing to a Tool of unknown, but repeatable length when executing a program

When running a program, it is easy to use tools of unknown but repeatable lengths, such as a

counter bore placed in an end mill holder. As long as the counter bore does not leave the end

mill holder, its length will repeat each time it is placed in the spindle. Since the tool length

remains the same, you can teach this length to

MILLPWR

when creating the program without

having to enter the tool into the Tool Library.

•

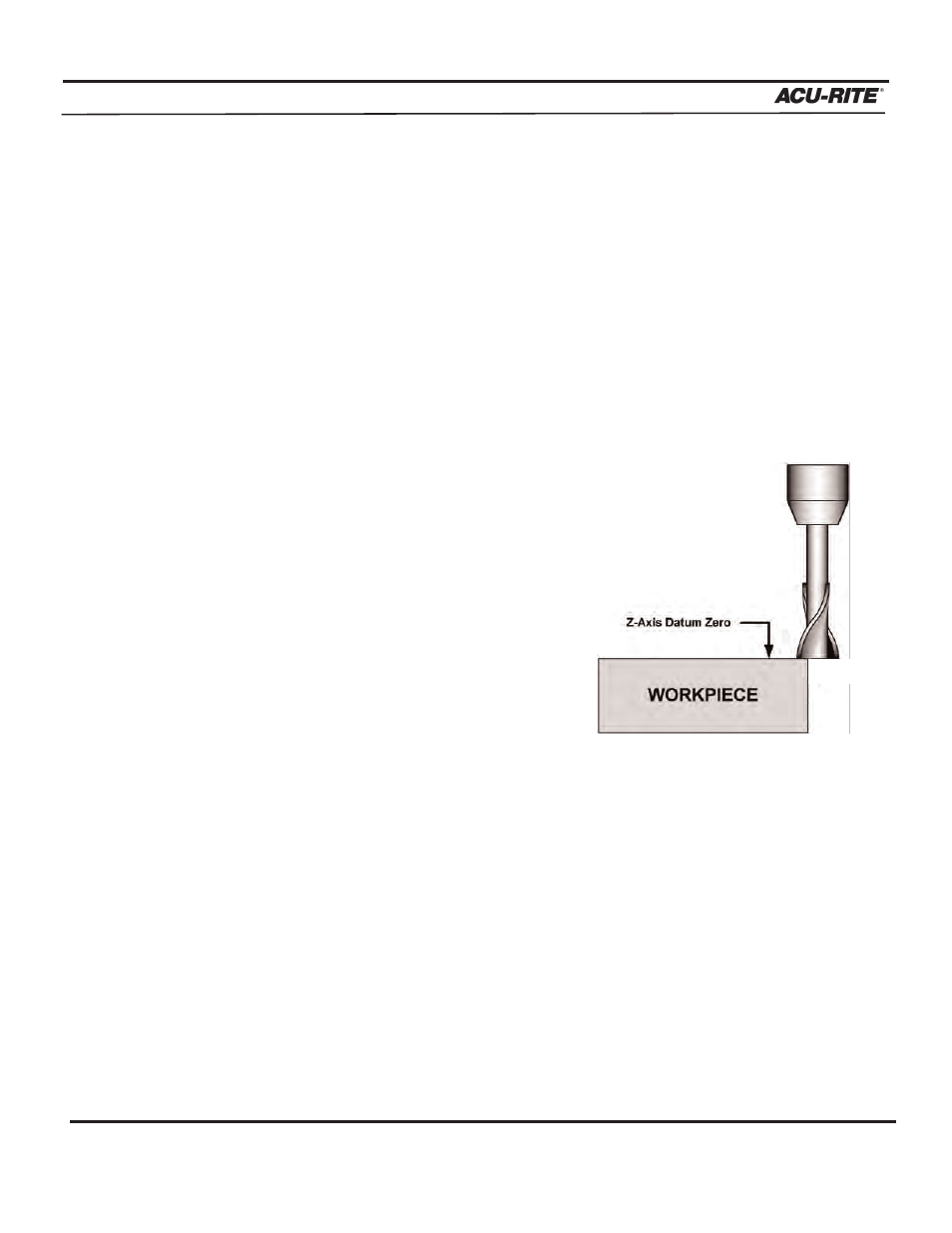

Be sure the Z-axis datum was set using a tool from

the library (See: Using the Tool Library above).

•

When programming the tool step, enter the tool

diameter, then place the tool in the spindle and touch

Z-datum.

•

Highlight the length field and press the

TEACH TOOL

LENGTH

softkey. The tool length offset will appear

in the length field.

•

Enter any of the remaining information you need in

the tool step and press

USE

.

When this tool step is executed, the length offset will take

effect and the tool tip will be offset correctly.

Changing to a Tool of unknown, non-repeatable length when executing a program

When running a program, it is possible to switch between tools of known length from the

library, to tools that have a non-repeatable length such as a counter-bore held in an R-8 collet.

Follow this program as an example:

Step 1 is a tool step, tool 1-a center drill-programmed from the tool library and is repeatable.

Step 2 in the program is a bolthole pattern.

Step 3 is a tool step using tool 2-a drill-from the library and is also repeatable.

Step 4 is the same hole pattern repeated.

Step 5 is a tool step programmed as a counter bore of unknown length and does not repeat.

Step 6 is the same hole pattern repeated.

7-9