Toshiba e-Studio Imaging 6520c User Manual

Page 28

e-STUDIO5520C/6520C/6530C

© 2008 TOSHIBA TEC CORPORATION All rights reserved

1-18

1. General Adjustments – Copying, Printing and e-Filing (Output from Box)

A large number of sheets are printed (hundreds of copies or more per day) and the image

quality needs to be constantly maintained:

Set the value for code 08-572 within a range of "1" to "9" (Value

× 100 sheets) to reduce the accumulated

number of printed sheets. It will determine the interval until the next image quality control is performed.

* After a copy or print job is completed, if the accumulated number of printed sheets exceeds the specified

value, image quality control will be performed.

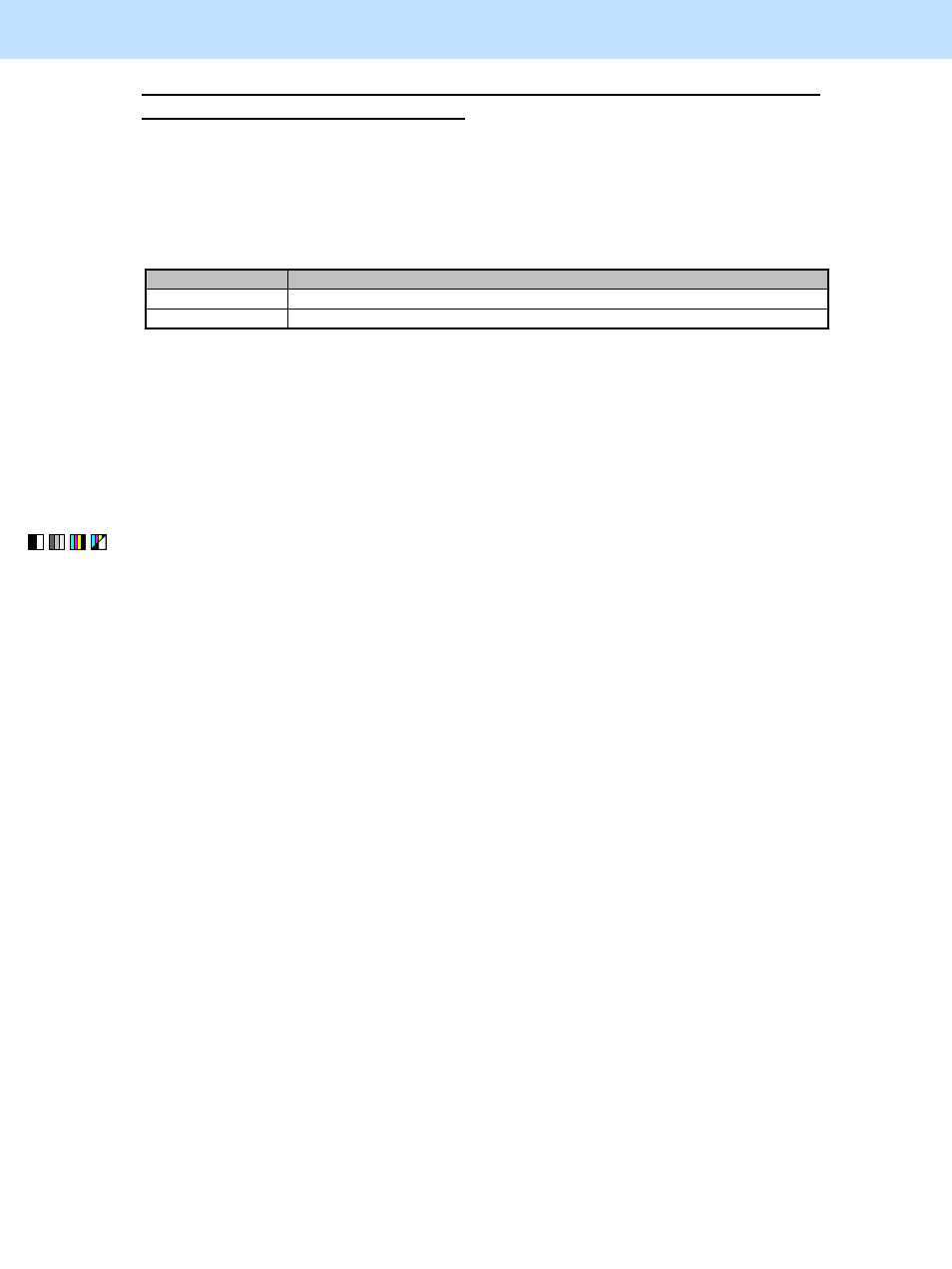

Value for 08-572 Accumulated number of printed sheets before image quality control is performed

1 to 9

100 to 900 sheets

10

1,000 sheets (default)

• After setting the value for code 08-572, forcibly perform image quality control, as follows:

Enter adjustment mode [05], select code [396], and then press the [START] button.

After performing the adjustment, print and check the image quality.

If further image quality adjustments are still necessary, use the next procedure.

(2) The image density or color during continuous printing on the plain paper can be stabilized by changing the

fusing related settings by means of the following procedures.

Procedures

Follow the procedure below.

(a) Change each value of the [08] codes [411-0] "Temperature of the fuser unit at ready status (Heat

roller) – normal temperature" and [407-0] "fusing temperature at ready status (side / fuser belt –

normal temperature)" from the default value (10: 170°C) to "9" in order to lower the temperature by

5°C. The same value must be set for the [08] codes [411-0] and [407-0] unless otherwise required.

(b) Change the value of the [08] code [5241-1] "fusing temperature correction at ready status (pressure

roller – normal temperature)" from the default value (2: 0°C) to "0" in order to lower the temperature

by 10°C. Change each value of the [08] codes [2124-0] "fusing temperature at ready status (center /

pressure roller – normal temperature)" and [5236-0] "fusing temperature at ready status (side /

pressure roller – normal temperature)" from the default value (4: 140°C) to "2" in order to lower the

temperature by 10°C. The same value must be set for the [08] codes [2124-0] and [5236-0] unless

otherwise required.

• Confirm if the firmware version is the latest one before the setting. If not, update it to the latest one.

• After these settings, the machine may go into the "wait" status since the fusing temperature can not follow

depending on the usage conditions, such as low temperature, thick paper, just recovering after warming up, etc.

• After these settings, the fusing performance may degrade depending on the usage conditions, such as low

temperature, thick paper, just recovering after warming up, etc. In such a case, return the setting to default.

• These settings extend the First Print Out Time by the period of time required for pre-running of the first

printing.

• These settings always perform the pre-running for the first printing of each job by the time required for pre-

running of the first print. This results in reducing the life of consumables.