HP Anab EQ5 User Manual

Page 108

EQ5 AC Drive Operations Manual

______________________________________________________________________

TECO – Westinghouse Motor Company Insulation Testing &Parts Replacement 102

7- 4 Insulation Test

It is not necessary to do an insulation test on the inverter as this was completed at the factory. If an

insulation test with a megger test must be completed, then proceed as described below as an

incorrect testing method may result in product damage.

If a dielectric strength test must be completed, the specifications for the test must be followed as

Improper testing may result in damage to the inverter. Please contact your local distributor or nearest

TWMC sales office for further guidance.

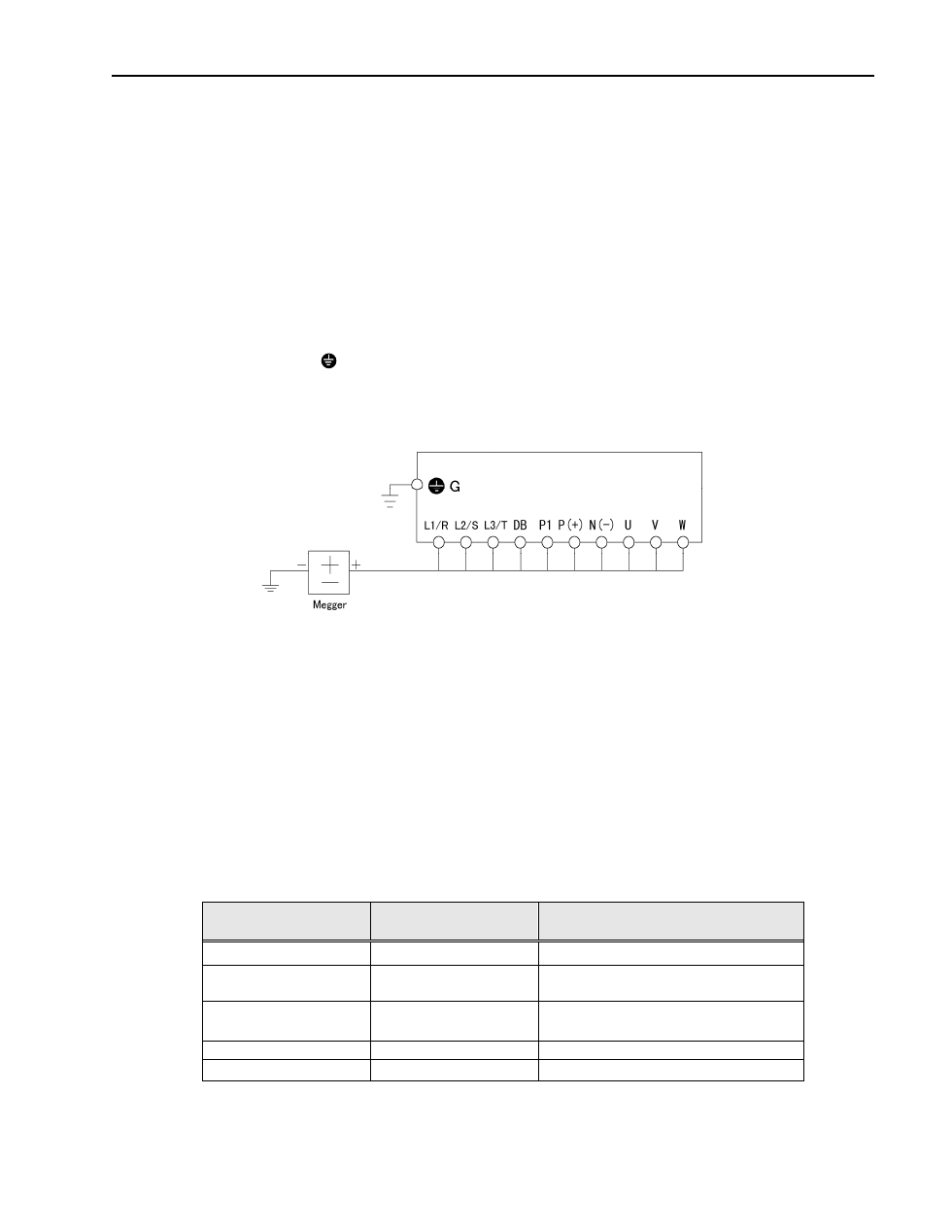

(1) Megger test for the main power circuit.

a - Use a 500V DC type megger and isolate the main power before commencing measurement.

b - If the test voltage is connected to the control circuit, remove all connection cables to the control

circuit.

c - Connect the main circuit terminals together using common cables as shown in Fig. 7-4-1.

d - Perform the megger test only between the common cables connected to the main circuit and the

ground (terminal G).

e - A megger indicating a reading of 5M

Ω or more is normal. (This is the value measured with only

the inverter connected.)

Fig. 7-4-1 Main Circuit Insulation Test

(2) Insulation test in the control circuit.

A megger test and a dielectric strength test must not be performed on the control circuit or damage

will result. To test the control circuit, use a high resistance range multimeter and proceed as follows.

a - Remove all external cables from the control circuit terminals.

b - Conduct a continuity test between the isolated control circuit grounds. A result of 1M

Ω or more is

normal.

(3) Exterior main circuit and sequence control circuit.

Remove all cables from inverter terminals to ensure the test voltage is not applied to the inverter.

7-5 Parts Replacement

The life expectancy of a part depends on the type of part, the environment, and usage

conditions. Parts should be replaced as shown in Table 7-5-1 Parts Replacement.

Table 7-5-1 Parts Replacement

Part Name

Standard Period for

Replacement

Comments

Cooling fan

3 years

Exchange for a new part.

Smoothing capacitor

5 years

Exchange for a new part (determine

after checking).

Electrolytic capacitor

on the PC board

7 years

Exchange for a new PC board

(determine after checking).

Fuse

10 years

Exchange for a new part.

Other parts

-

Determine after checking.