Eq5 ac drive operations manual – HP Anab EQ5 User Manual

Page 100

EQ5 AC Drive Operations Manual

_______________________________________________________________________

TECO – Westinghouse Motor Company Trouble Shooting Chart 94

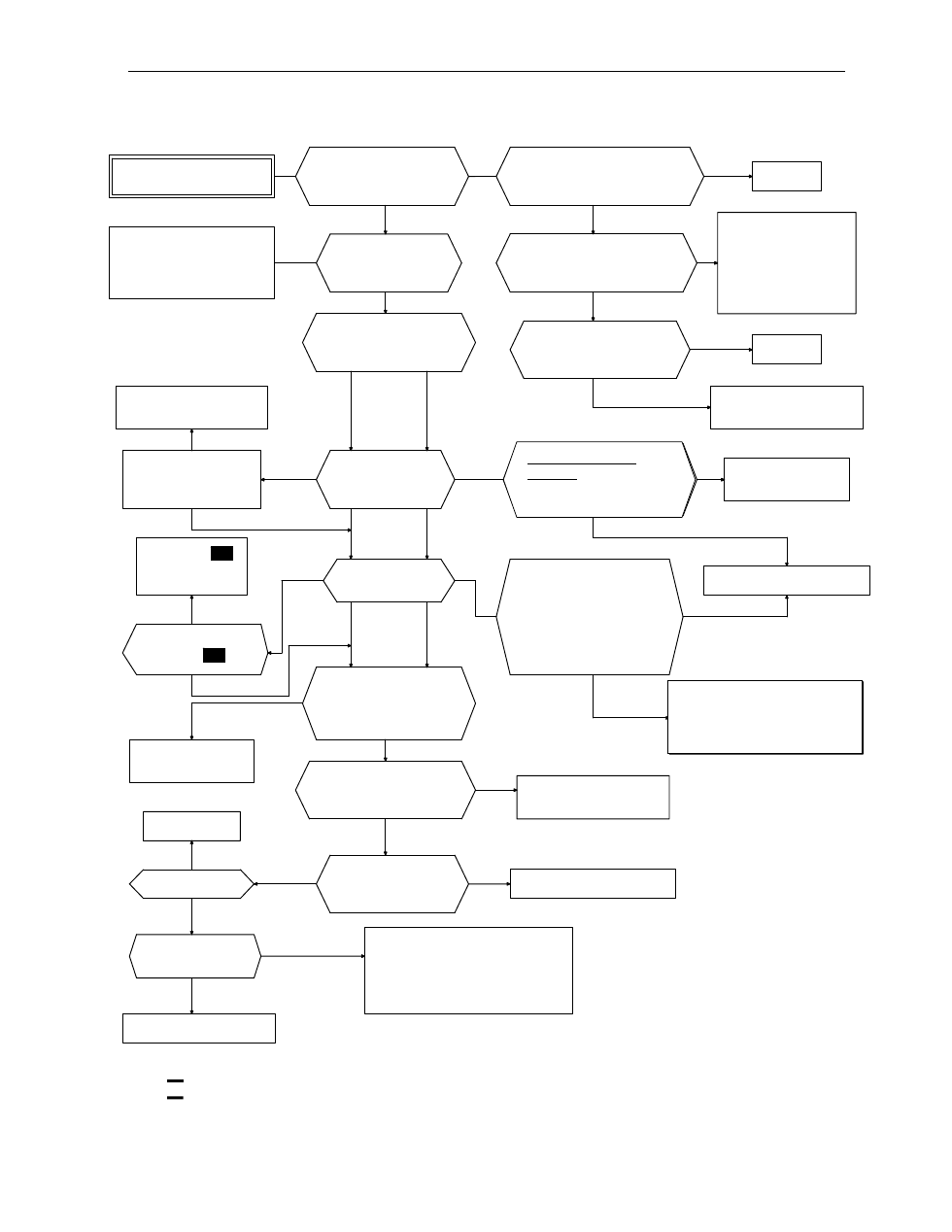

6-4 Abnormal motor rotation

(1) If motor does not rotate

YES

NO

YES

YES

NO

NO

YES

NO

YES

Motor does not rotate.

Charge lamp (CRG)

lights and LCD monitor

lights up?

Are the circuit breaker and

magnetic contactor on the

power supply side switched on?

Turn on.

Is the LCD monitor

displaying an alarm

mode screen?

Is operation method

the keypad panel or

control terminal input?

Is a jumper or DC reactor

connected between

terminals P1 and P(+)?

Connect.

If no error is detected,

continue operation.

Keypad

panel

Control

terminals

Does the motor run

if FWD or REV is

pressed?

Was the forward or

reverse operation

command given?

Replace the faulty

switch or relay.

Has the frequency

been set?

Correct the wiring error.

Set the frequency

correctly.

Are the inverter output

terminals (U,V,W) provided

with the proper voltage?

Faulty motor

Excessive load?

Correct the wiring error.

Is the torque boost

set correctly?

The load is excessive,

resulting in motor lock.

Reduce the load and check

that the brake is released

(if a mechanical brake is used).

NO

NO

Remove the cause of

alarm function activation

and reset the alarm,

then run the motor.

YES

YES

Are the voltages

on the power terminals

(R/L1, S/L2, T/L3) normal?

NO

YES

YES

NO

NO

YES

NO

YES

YES

NO

NO

YES

NO

NO

Replace the faulty

frequency setting POT (VR)

, signal converter, switch,

or relay contacts as required.

NO

Check for problems

(low voltage,

an open-phase,

a loose connection,

poor contact) and

remedy accordingly.

Are the frequency limiter

(High) and the frequency

setting lower than

the starting frequency?

YES

Are the cables to

the motor connected

correctly?

YES

NO

NO

YES

NO

YES

Raise the torque boost.

YES

Note: Monitor the operation

command or frequency setting

values, etc., on the LED or LCD

monitor after selecting

the respective functions.

Is the external wiring

between control terminals

13, 12, 11, C1and V2 or

between X1-X9 and

CM for the multistep

frequency selection

connected correctly?

Inverter may be faulty.

Contact TWMC.

Press the

key and set

the frequency.

Does the motor start

when the key

is pressed?

Are external wiring between

control circuit terminals

FWD, REV -CM

connected correctly?

Inverter may be faulty.

Contact TWMC.

The motor does not rotate if the following commands are issued.

An operation command is issued while the coast-to-stop or DC braking command is output

A reverse operation command is issued with the “H08 Rev. phase sequence lock” value set to 1.

∧

Are external wiring

between control circuit

terminals FWD, REV-

CM connected

Replace the faulty

frequency setting POT (VR),

signal converter, switch,

or relay contacts as required.

∧