Maintenance and inspection, Danger – HP Anab EQ5 User Manual

Page 103

_______________________________________________________________________

TECO – Westinghouse Motor Company Maintenance & Inspection 97

7. Maintenance and Inspection

It is recommended that daily and periodic inspections be carried out to insure trouble-free operation

and long-term reliability. The following are recommendations for conducting these inspections.

7-1 Daily Inspection

During operation, a visual inspection for abnormal operation can be completed externally without

removing the covers.

The inspections should cover the following:

(1) The performance is as expected and is within specifications.

(2) The environment conforms to the drive specifications.

(3) The digital operator is functioning normally.

(4) There are no abnormal sounds, vibrations, or odors.

(5) There are no indications of overheating or discoloration.

7-2 Periodic Inspections

Periodic inspections are carried out after stopping drive operations, disconnecting the power source,

and removing the protective cover(s).

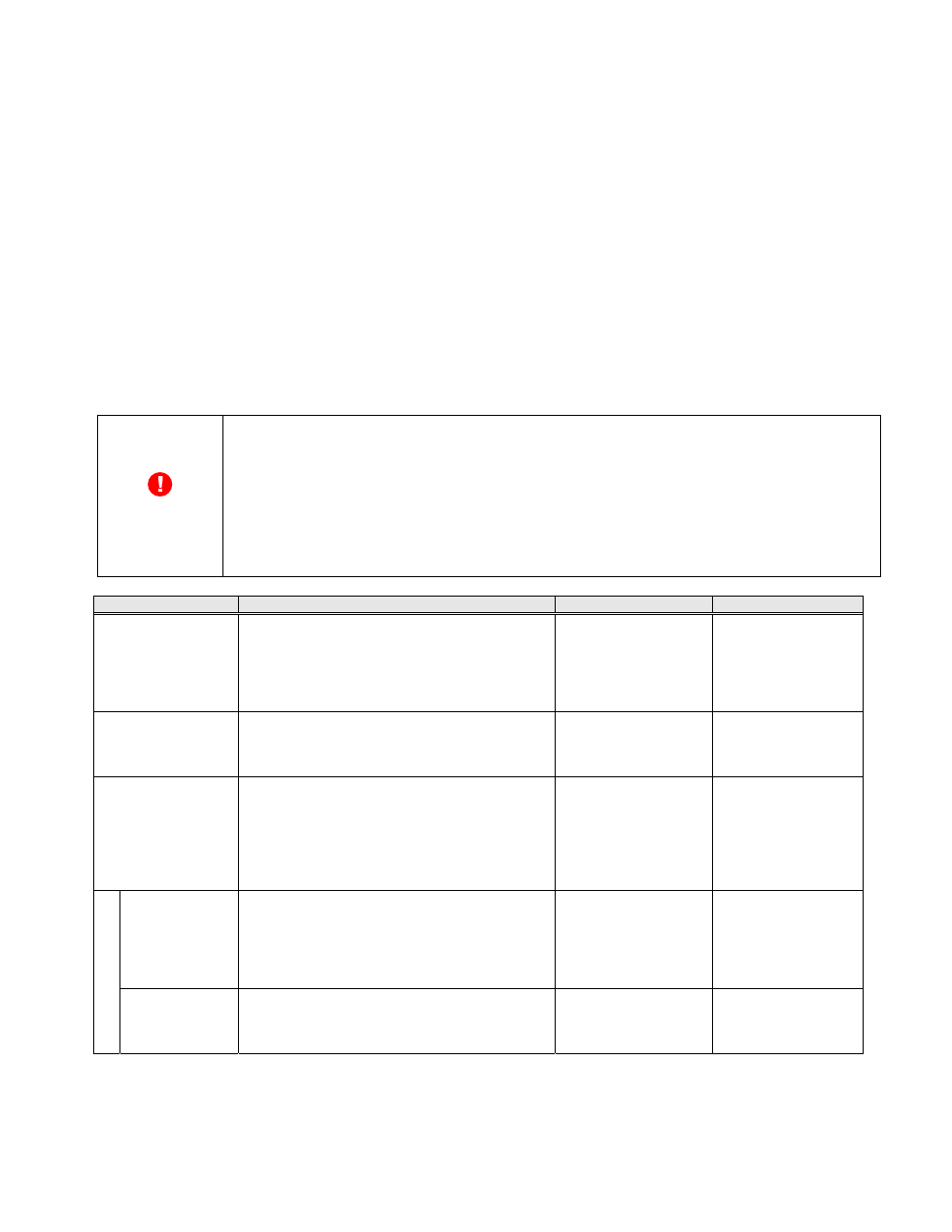

DANGER

•

Because the large capacitors in the main DC circuit retain lethal voltage levels after power

is disconnected and take time to discharge, wait at least five minutes after turning off the

power supply for inverter rated at 30HP/CT, 40HP/VT or less, and ten minutes for inverter

rated at 40HP/CT, 50HP/VT or more. (Check that the charge lamp (CRG) is off, and that

the voltage is 25V DC or less between terminals P(+) and N(-). Otherwise, electric shock

or injury may result.

•

Only authorized personnel should carry out maintenance and component replacement

operations. (Remove metal jewelry such as watches and rings and use insulated tools.)

•

Never modify the inverter. Otherwise, electric shock or injury may result.

Table 7-2-1 Periodic Inspection List

Area to Check

Items to Check

How to Inspect

Evaluation Criteria

Environment

1) Check the ambient temperature, humidity,

Vibration and atmosphere (dust, gas, oil mist,

water drops).

2) Is the area surrounding the equipment free of

foreign objects?

1) Conduct visual

inspection and use

the appropriate

equipment.

2) Visual inspection.

1)Results comply

with specifications.

2) The area is clear.

Digital operator

1) Is the display hard to read?

2) Are the characters complete?

1) Visual inspection.

2) Visual inspection.

1) The display can be

read.

2) Characters are

complete.

Structure

(frame & cover)

1) Is there abnormal sounds or vibration?

2) Are fasteners loose?

3) Is there deformation or damage?

4) Is there discoloration as a result of

overheating?

5) Are there stains or accumulated dust?

1) Visual and aural

Inspection.

2) Tighten.

3) Visual inspection.

4) “

5) “

1) No abnormalities

2) “

3) “

4) “

5) “

Main circuit

Common

1) Are there loose or missing fasteners?

2) Is there deformation, cracks, damage, and

discoloration due to overheating or

deterioration in the equipment and insulation?

3) Are there stains and accumulated dust?

1) Tighten.

2) Visual inspection.

3) “

1) No abnormalities

2) No abnormalities

Note: Discoloration

of the bus bar does

3) not indicate a

problem.

Conductor and

wire

1) Is there discoloration or distortion of a

conductor(s) due to overheating?

2) Are there cracks, crazing or discoloration of

the cable sheath?

1) Visual inspection.

2) “

1) No abnormalities

2) “

Cont.