3 flame detector – AERCO BMK 2000DF User Manual

Page 94

Benchmark 1500DF - 2000DF Boilers

CHAPTER 7 – MAINTENANCE

Page 94 of 196

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

OMM-0098_0A

04/01/2014

Ph.: 800-526-0288

GF-144

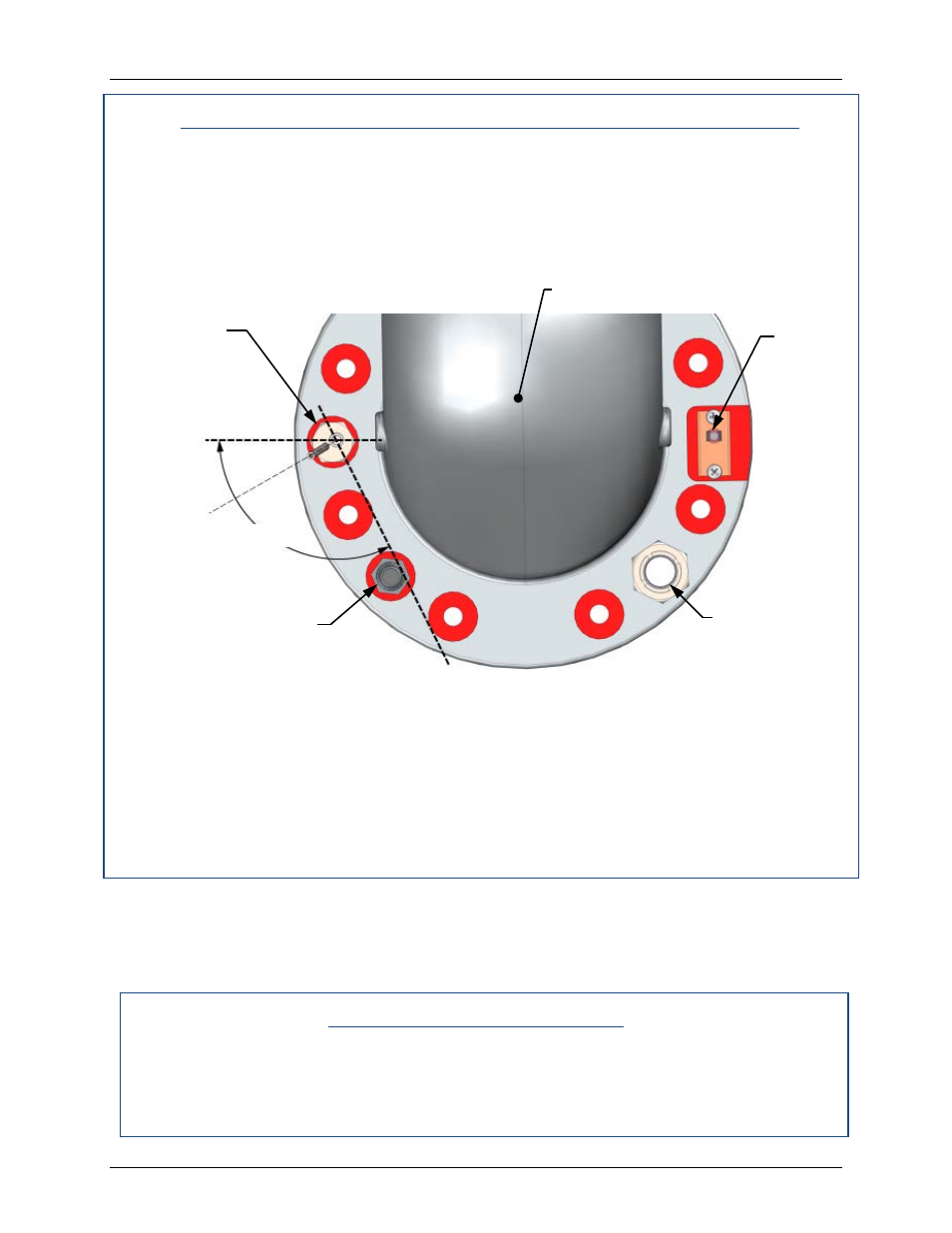

IGNITER-INJECTOR MAINTENANCE PROCEDURES – Continued

NOTE

If a replacement igniter-injector (part no. 66026) is being installed,

a compression nut containing a built-in ferrule will be included with

the replacement part. If needed, 3 indexing washers are also

included These washers may be needed to properly position the

gas injector tube of the igniter-injector within the 120° angle range

shown in Figure 7-3.

Figure 7-3: Igniter-Injector Orientation (Viewed Looking Down from Above)

10.

Reinstall the igniter-injector in the burner plate. Torque to 170 - 180 in-lbs. DO NOT over

tighten.

11.

Connect the staged ignition assembly to the gas injector tube of the igniter-injector by

securing the compression nut to the elbow of the staged ignition assembly.

12.

Reconnect the igniter-injector cable.

13.

Reinstall the shroud on the unit.

7.3 FLAME DETECTOR

The flame detector (part no. 66020) is located on the burner plate at the top of the unit (see

Figures 7-1 and 7-2). The flame detector may be hot. Allow the unit to cool sufficiently before

removing the flame detector. Inspect or replace the flame detector as follows:

Flame Detector Maintenance

1.

Set the control panel ON/OFF switch to the OFF position. Disconnect AC power from the

unit.

2.

Remove the top shroud from the unit by grasping the top handle and lifting straight up.

This will disengage the shroud from the four (4) pins in the side panels.

O2 SENSOR

BLOWER PLENUM

IGNITER-

INJECTOR

FLAME

OBSERVATION

PORT

ANGLE OF GAS

INJECTOR

TUBE

120°

FLAME

ROD