AERCO BMK 2000DF User Manual

Page 62

Benchmark 1500DF - 2000DF Boilers

CHAPTER 4 – INITIAL START-UP

Page 62 of 196

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

OMM-0098_0A

04/01/2014

Ph.: 800-526-0288

GF-144

PROPANE Combustion Calibration – Continued

23. Next, press the down (▼) arrow key until CAL Voltage 80% is displayed.

24. Press the CHANGE key and observe that CAL Voltage 80% is flashing.

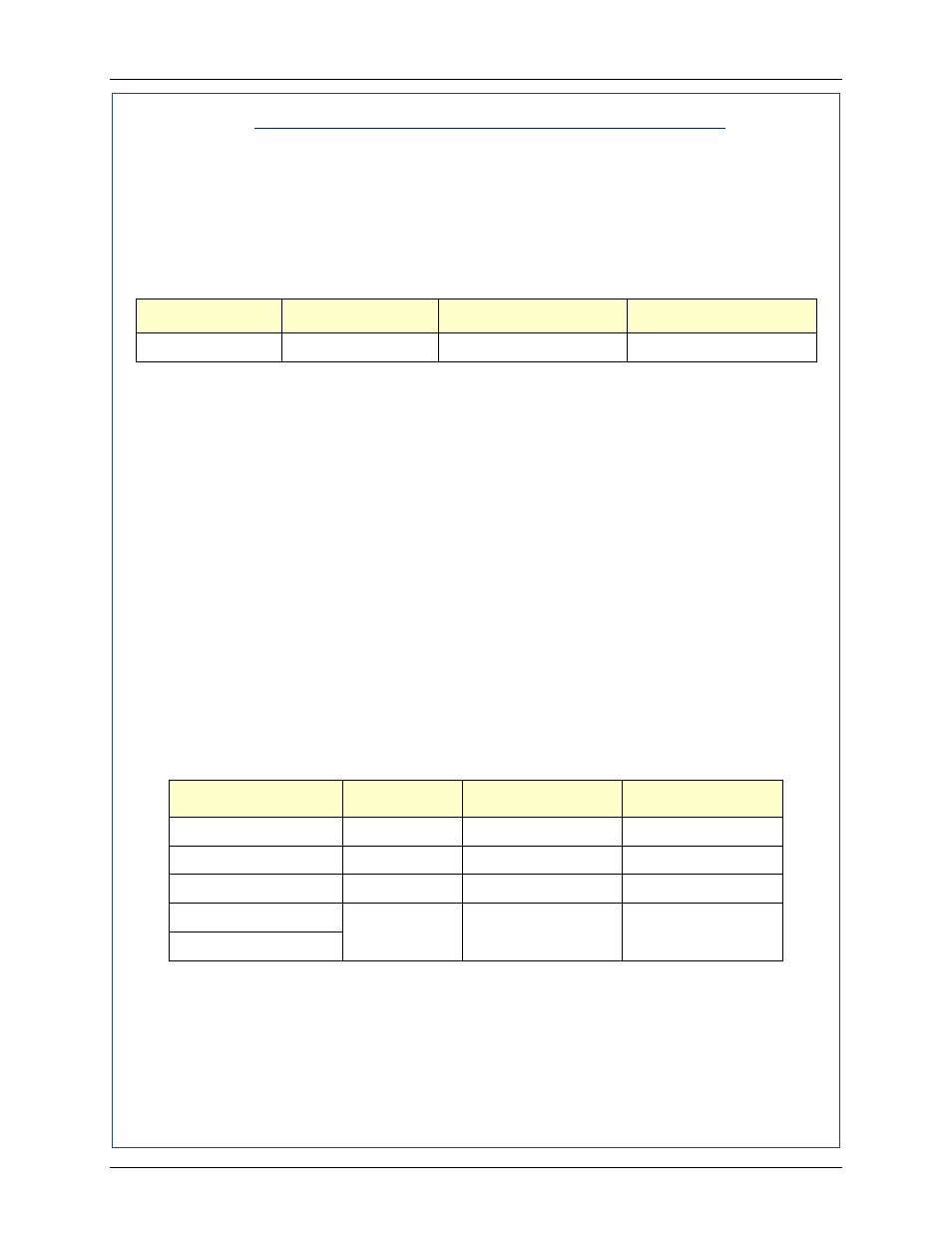

25. The oxygen level at the 80% valve position should be as shown below. Also, ensure that

the nitrogen oxide (NOx) and carbon monoxide (CO) readings do not exceed the

following values:

Combustion Calibration Readings – 80% valve Position

Valve Position

Oxygen (O

2

) %

Nitrogen Oxide (NOx)

Carbon Monoxide (CO)

80%

5.4% ± 0.5%

≤50 ppm

<150 ppm

26. If the oxygen level is not within the specified range, adjust the level using the ▲ and ▼

arrow keys. This will adjust the output voltage to the blower motor as indicated on the

display. Pressing the ▲ arrow key increases the oxygen level and pressing the down ▼

arrow key decreases the oxygen level.

27. Once the oxygen level is within the specified range at 80%, press the ENTER key to

store the selected blower output voltage for the 80% valve position. Record all readings

on the Combustion Calibration Sheets provided.

28. Repeat steps 20 through 27 for valve positions of 60%, 45%, 30% and 18% (on the BMK

1500DF only) or 16% (on the BMK 2000DF only). The oxygen (O

2

), nitrogen oxide (NOx)

and carbon monoxide (CO) should remain within the same limits for all valve positions as

shown in the following table.

NOTE

If NOx readings exceed the target values shown (<50 ppm),

increase the O

2

level up to 1% higher than the listed calibration

range shown in the table. Record the increased O

2

value on the

Combustion Calibration sheet.

Combustion Calibration Readings

Valve Position

Oxygen (O

2

)

%

Nitrogen Oxide

(NOx)

Carbon Monoxide

(CO)

60%

5.5% ± 0.5

<50 ppm

<150 ppm

45%

5.5% ± 0.5

<50 ppm

<150 ppm

30%

6.3% ± 0.5

<50 ppm

<150 ppm

18% BMK 1500DF

6.0% ± 0.5

<50 ppm

<150 ppm

16% BMK 2000DF

29. If the oxygen level at the 18% (BMK1500DF) or 16% (BMK2000DF) valve position is too

high and the Blower voltage is at the minimum value, you can adjust the idle screw (TAC

valve) which is recessed in the top of the Air/Fuel Valve (see Figure 4-4). Rotate the

screw 1/2 turn clockwise (CW) to add fuel and reduce the O

2

to the specified level.

Recalibration MUST be performed again from 60% down to 18% (BMK1500DF) or 16%

(BMK2000DF) after making a change to the idle screw (TAC valve).

30. This completes the PROPANE combustion calibration procedure.