AERCO BMK 2000DF User Manual

Page 105

Benchmark 1500DF - 2000DF Boilers

CHAPTER 8 – TROUBLESHOOTING GUIDE

OMM-0098_0A

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

Page 105 of 196

GF-144

Ph.: 800-526-0288

04/01/2014

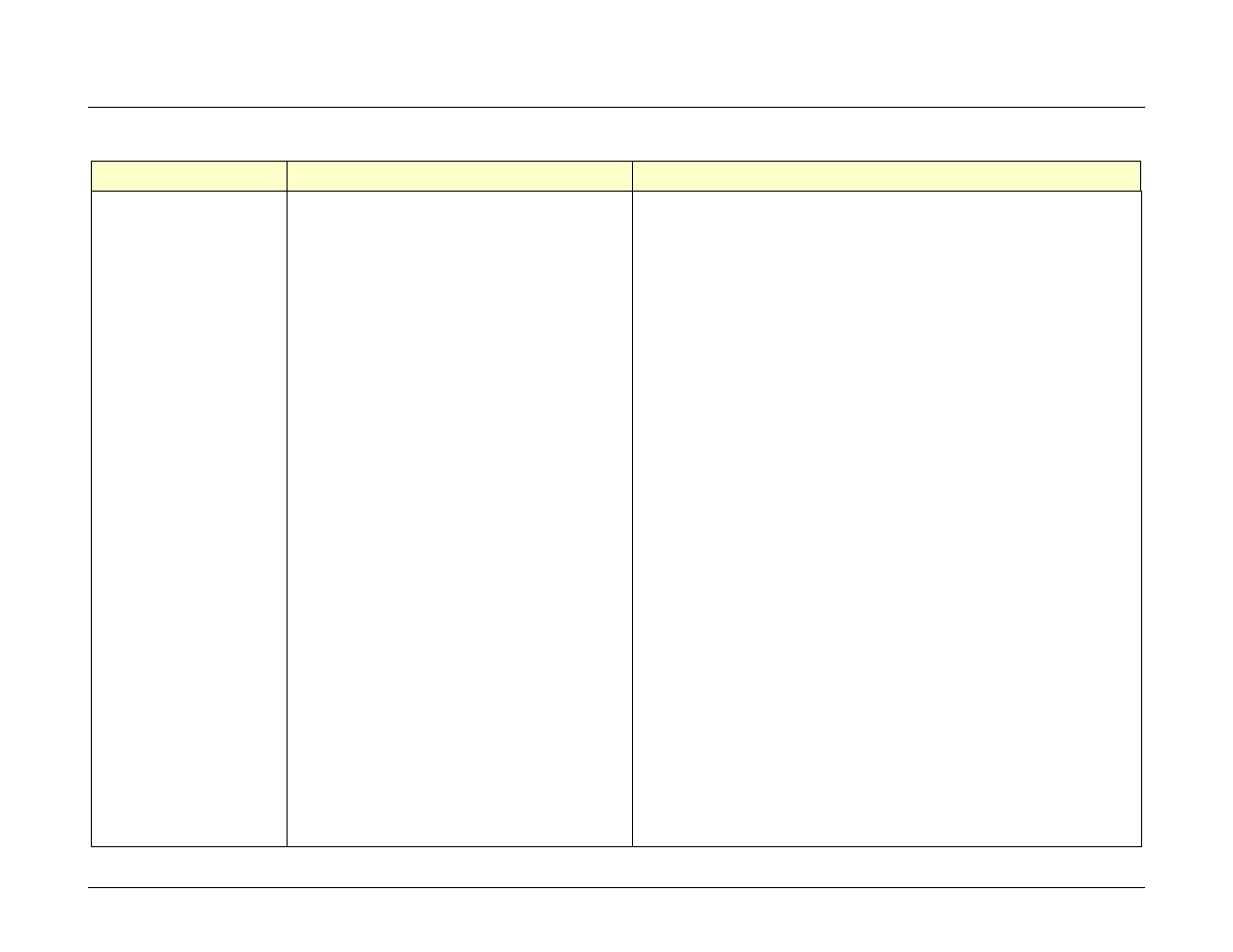

TABLE 8-1: BOILER TROUBLESHOOTING

FAULT INDICATION

PROBABLE CAUSES

CORRECTIVE ACTION

AIRFLOW FAULT

DURING IGNITION

1.

Blower stopped running due to thermal

or current overload.

2.

Blocked Blower inlet or inlet air filter.

3.

Blockage in Blower Proof switch.

4.

Blockage in Blocked Inlet switch.

5.

Defective Blower Proof switch.

6.

Defective Blocked Inlet switch.

7.

Loose temperature to AUX connection in

I/O Box.

8.

Defective temperature sensor.

9.

Loose wire connection between the 0-

10V signal from I/O box to the Blower

input.

10.

Defective I/O Box.

11.

Wrong 0-10V output selection on the

control box.

12.

Defective Air-Fuel Valve potentiometer.

13.

Hard light.

1.

Check combustion blower for signs of excessive heat or high

current drain that may trip thermal or current overload devices.

2.

Inspect the inlet to the combustion blower including the air

filter at the air/fuel valve for signs of blockage.

3.

Remove the Blower Proof switch and inspect for signs of

blockage, clean or replace as necessary.

4.

Remove the Blocked Inlet switch and inspect for signs of

blockage, clean or replace as necessary.

5.

Check the continuity of the Blower Proof switch with the

combustion blower running. If there is an erratic resistance

reading or the resistance reading is greater than zero ohms,

replace the switch.

6.

Turn off unit and check the continuity of the Blocked Inlet

switch. If there is an erratic resistance reading or the

resistance reading is greater than zero ohms, replace the

switch.

7.

Check the actual inlet air temperature and measure voltage at

AUX input in the I/O Box. Verify that the voltage conforms to

the values shown in the tabular listing provided in Appendix C.

8.

Refer to CORRECTIVE ACTION 7 and verify that the voltage

conforms to the values shown in Appendix C.

9.

Check wire connection from I/O Box 0-10V signal to the

Blower Motor.

10.

Measure voltage at the I/O box 0-10V output. A voltage of

10V equates to a 100% open valve position.

11.

Check the Analog Out option on the C-More Configuration

Menu. Valve Position 0-10V should be selected.

12.

Check Air/Fuel Valve position at 0%, 50% and 100% open

positions. The positions on the VALVE POSITION bargraph

should match the readings on the Air/Fuel Valve dial.

13.

Check igniter-injector for soot or erosion of electrode. Check

injector solenoid valve to insure proper open/close operation.