AERCO BMK 2000DF User Manual

Page 112

Benchmark 1500DF - 2000DF Boilers

CHAPTER 8 – TROUBLESHOOTING GUIDE

Page 112 of 196

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

OMM-0098_0A

04/01/2014

Ph.: 800-526-0288

GF-144

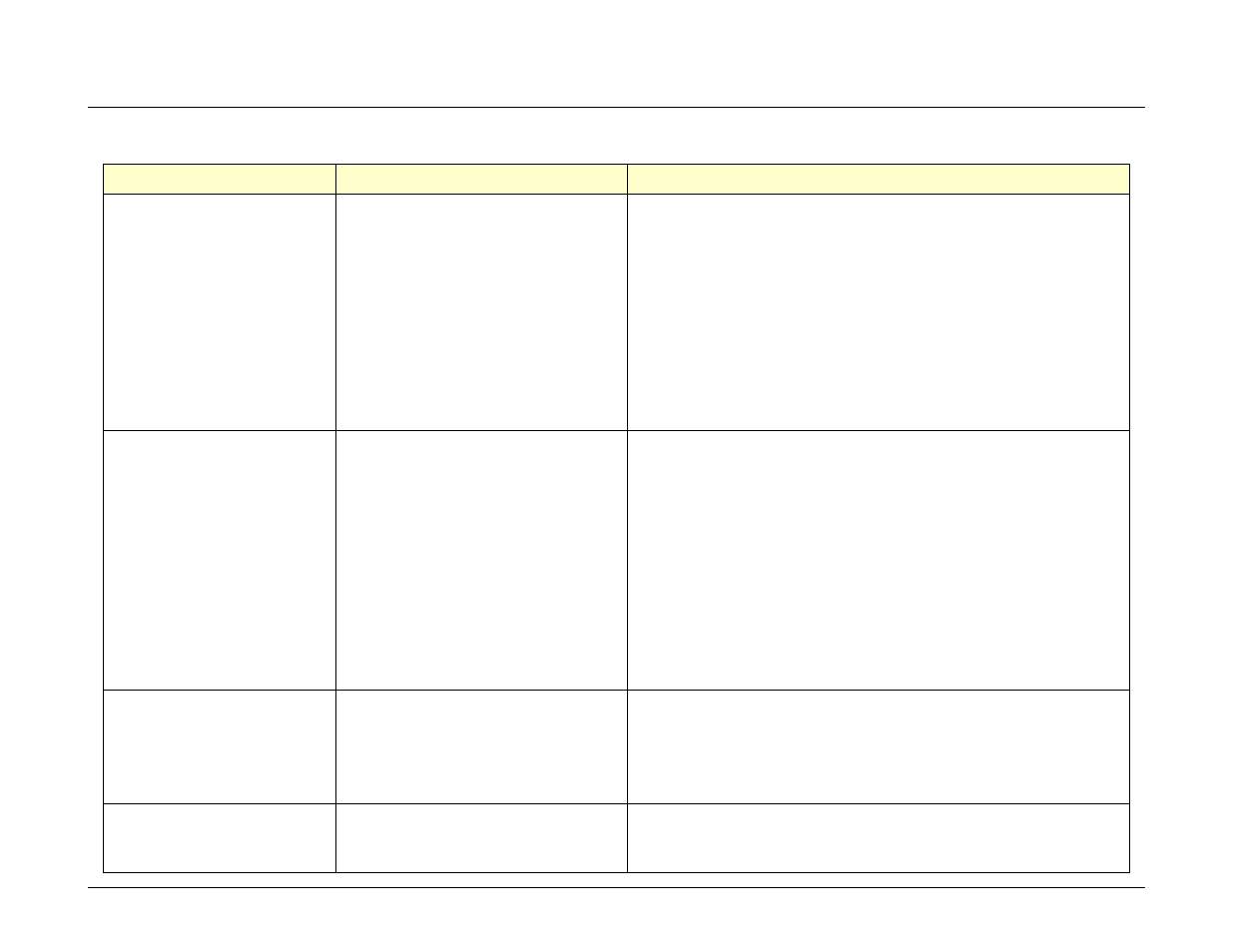

TABLE 8-1: BOILER TROUBLESHOOTING – Continued

FAULT INDICATION

PROBABLE CAUSES

CORRECTIVE ACTION

(continued)

2.

Defective or shorted switch.

3.

Switch wired incorrectly.

4.

Defective Power Supply Board or

fuse.

5.

Defective IGST Board.

2.

If the Air/Fuel Valve does rotate to the ignition position, check

the purge switch for continuity between the N.O. and COM

terminals. If the switch shows continuity when not in contact

with the cam, check to ensure that the switch is wired

correctly (correct wire numbers on the normally open

terminals).

3.

If the switch is wired correctly, replace the switch.

4.

Check DS1 & DS2 LEDs on Power Supply Board. If they are

not steady ON, replace Power Supply Board.

5.

Check “Heartbeat” LED DS1 and verify it is blinking ON &

OFF every second. If not, replace IGST Board.

PRG SWTCH OPEN

DURING PURGE

1.

Defective purge switch.

2.

No voltage present at switch.

3.

Switch wired incorrectly.

4.

Defective Power Supply Board or

fuse

5.

Defective IGST Board.

1.

If the air-fuel valve does rotate, check purge switch for

continuity when closing. Replace switch if continuity does not

exist.

2.

Measure for 24 VAC from each side of the switch to ground. If

24VAC is not present, refer fault to qualified service

personnel.

3.

Check to ensure that the switch is wired correctly (correct

wire numbers on the normally open terminals).

4.

Check DS1 & DS2 LEDs on Power Supply Board. If they are

not steady ON, replace Power Supply Board.

5.

Check “Heartbeat” LED DS1 and verify it is blinking ON &

OFF every second. If not, replace IGST Board.

OUTDOOR TEMP

SENSOR FAULT

1.

Loose or broken wiring.

2.

Defective Sensor.

3.

Incorrect Sensor.

1.

Inspect Outdoor Temperature sensor for loose or broken

wiring.

2.

Check resistance of sensor to determine if it is within

specification.

3.

Ensure that the correct sensor is installed.

O2 % OUT OF RANGE

1.

Combustion Calibration incorrect.

2.

Blocked inlet air duct or louver.

1.

Check Combustion Analyzer and recalibrate the boiler.

2.

Unblock air inlet and measure open area for combustion air to

the room.