7 condensate drain & piping – AERCO BMK 2000DF User Manual

Page 20

Benchmark 1500DF - 2000DF Boilers

CHAPTER 2 – INSTALLATION

Page 20 of 196

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

OMM-0098_0A

04/01/2014

Ph.: 800-526-0288

GF-144

are allowed in the discharge line. In multiple unit installations the discharge lines must not be

manifolded together. Each must be individually run to a suitable discharge location.

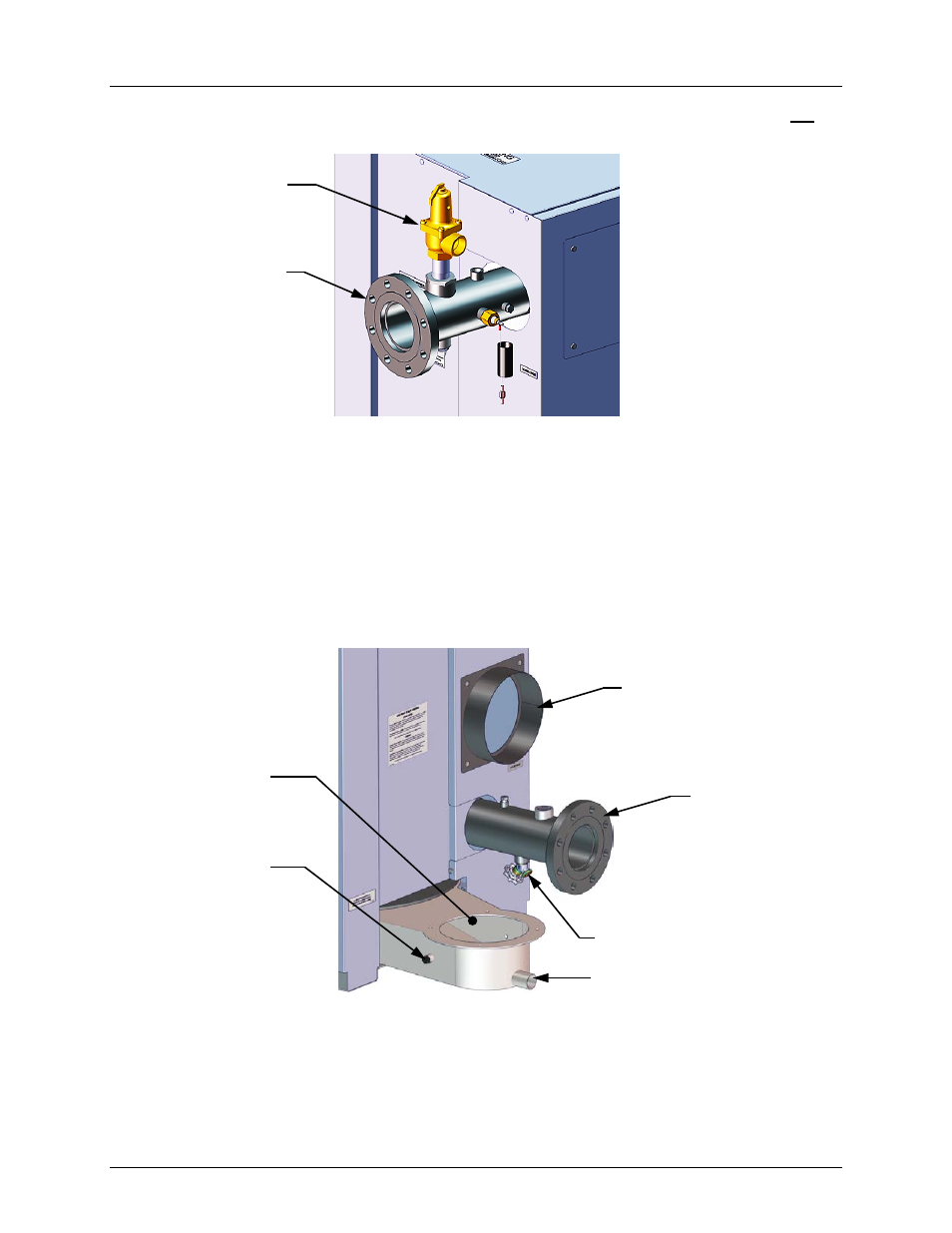

Figure 2-4: P&T Relief Valve Location

2.7 CONDENSATE DRAIN & PIPING

The Benchmark Boiler is designed to condense water vapor from the flue products. Therefore,

the installation must have provisions for suitable condensate drainage or collection.

The condensate drain port located on the exhaust manifold (Figure 2-5) must be connected to

the condensate trap (P/N 24060) which is packed separately within the unit’s shipping container.

The condensate trap inlet features two integral O-rings and a thumbscrew to allow direct

connection of the drain port into the trap inlet. See the Condensate trap Installation instructions

and Figure 2-6 on the next page.

Figure 2-5: Condensate Drain Connection Location

A sample condensate trap installation is shown in Figure 2-6. The following general guidelines

must be observed to ensure proper condensate drainage:

•

The condensate trap inlet (Figure 2-6) must be level the exhaust manifold drain port.

•

The base of the condensate trap must be supported to ensure that it is level (horizontal).

•

The trap must be removable for routine maintenance.

PRESSURE

RELIEF VALVE

4” HOT BOILER

WATER OUTLET

AIR INLET

PRIMARY

WATER INLET

DRAIN VALVE

CONDENSATE DRAIN PORT

1/4” ANALYZER

NPT PORT

EXHAST

MANIFOLD