3 high gas pressure test – AERCO BMK 2000DF User Manual

Page 79

Benchmark 1500DF - 2000DF Boilers

CHAPTER 6 – SAFETY DEVICE TESTING

OMM-0098_0A

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

Page 79 of 196

GF-144

Ph.: 800-526-0288

04/01/2014

Low Gas Pressure Fault Test – Continued

7. The unit should shut down and display a GAS PRESSURE fault message at

approximately 2.6” W.C..

8. Fully open the external manual gas shut-off valve and press the CLEAR button on the

Control Box.

9. The fault message should clear and the FAULT indicator should go off. The unit should

restart.

10. Upon test completion, close the ball valve and remove the manometer. Replace the 1/4“

plug removed in step 1.

6.3 HIGH GAS PRESSURE TEST

The instructions below apply to both the BMK 1500DF and BMK 2000DF and to both the

NATURAL GAS and PROPANE gas trains.

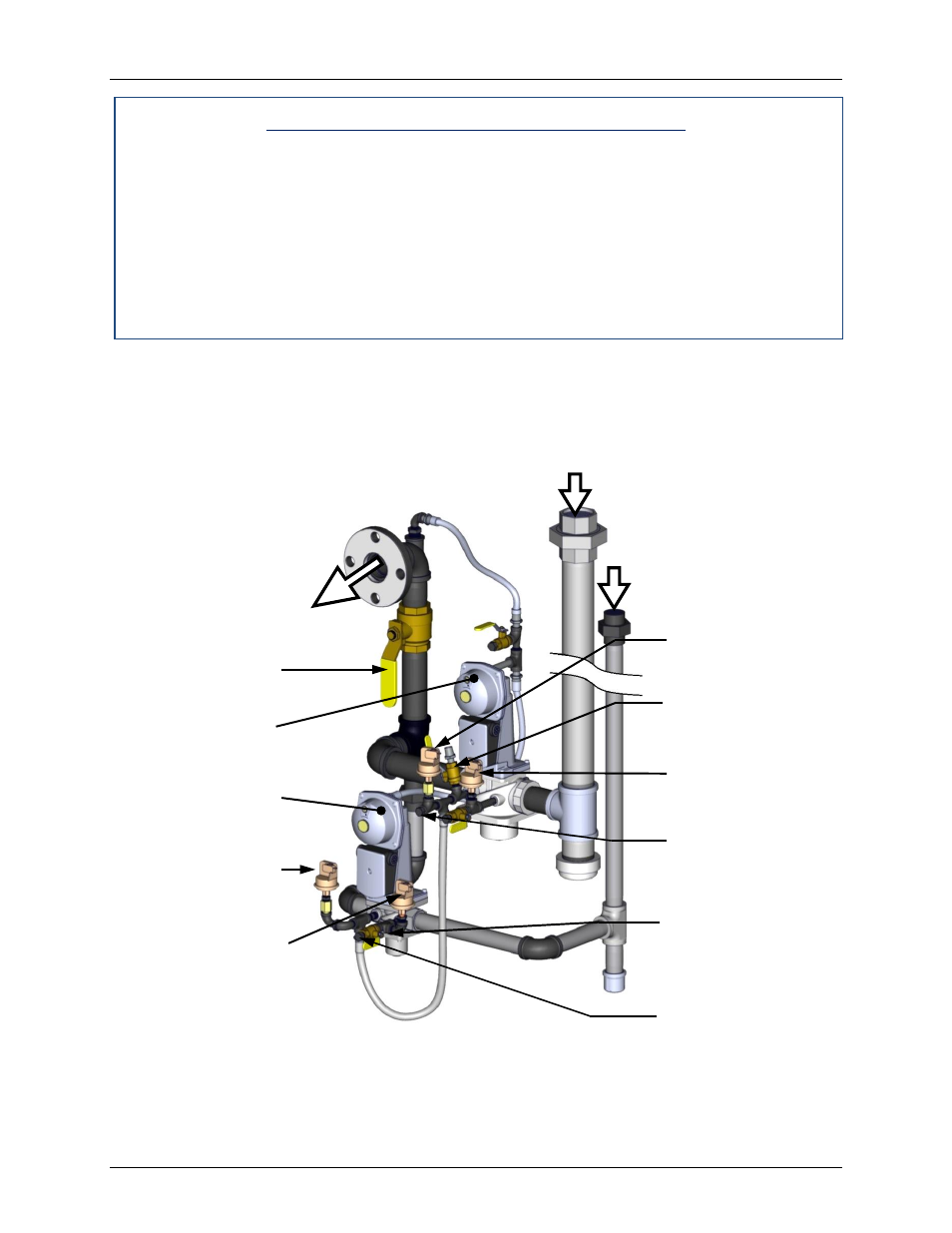

Figure 6-1b:

BMK 1500DF/2000DF:

High Gas Pressure Fault Test

To simulate a high gas pressure fault, refer to Figure 6-1b and perform the following steps:

TO AIR/FUEL VALVE

MANUAL SHUT-

OFF VALVE

NATURAL GAS

LOW GAS PRESSURE

SWITCH

NATURAL GAS

HIGH GAS

PRESSURE SWITCH

PROPANE

SSOV

PROPANE INLET

NATURAL GAS

SSOV

PROPANE

LOW GAS PRESSURE

SWITCH

PROPANE

HIGH GAS PRESSURE

SWITCH

1/4” NPT PLUG

(Install manometer here for

NATURAL GAS

HIGH gas

pressure fault test

1/4” NPT PLUG

(Install manometer here for

PROPANE

HIGH gas pressure

fault test

NATURAL GAS INLET

NATURAL GAS

HIGH GAS PRESSURE

LEAK

DETECTION

BALL VALVE

PROPANE

GAS

LEAK DETECTION

BALL VALVE