Chapter 10. boiler sequencing technology, 1 introduction, Chapter 10 – AERCO BMK 2000DF User Manual

Page 123: Boiler sequencing technology

Benchmark 1500DF - 2000DF Boilers

CHAPTER 10. BOILER SEQUENCING TECHNOLOGY

OMM-0098_0A

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

Page 123 of 196

GF-144

Ph.: 800-526-0288

04/01/2014

CHAPTER 10. BOILER SEQUENCING TECHNOLOGY

10.1 INTRODUCTION

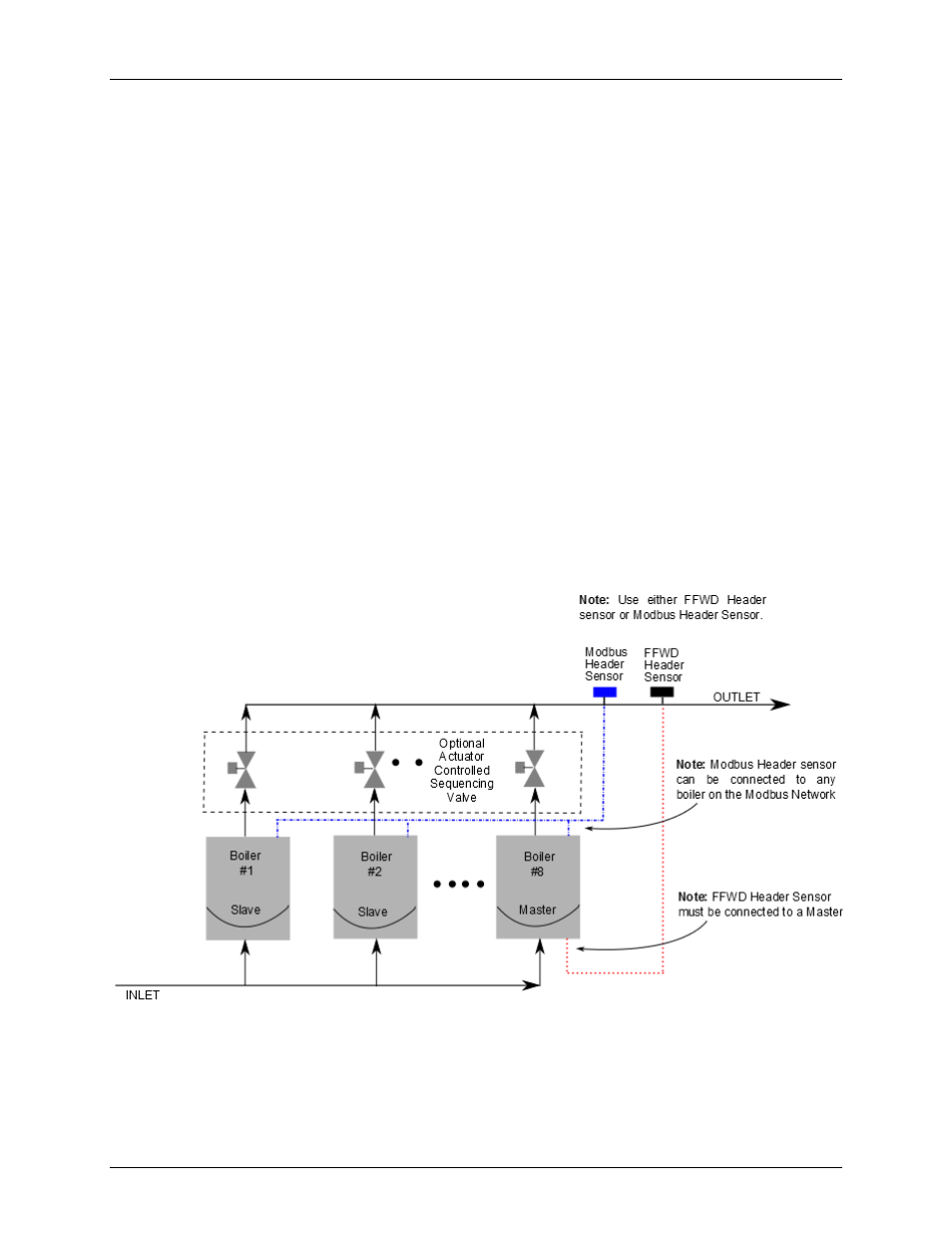

The C-More on-board Boiler Sequencing Technology system (BST) is an integrated 8 boiler

control system designed into the C-More controller. The BST has its own sophisticated PID

control system designed to simultaneously control the light off and modulation of up to 8 boilers

while achieving maximum operational efficiency.

BST is designed to ensure that all Boilers in the system operate at maximum efficiency. This is

accomplished by lighting off boilers only if all ignited boilers reach or exceed a defined Valve

Position (Fire Rate). Operating all boilers below the defined Fire Rate “Next on VP” (for Next

Turn on Valve Position) insures that they are firing at their most efficient Fire Rate. One C-More

unit is defined as the MASTER unit and all other C-More units on the BST Modbus Network are

defined as SLAVE units. The Master unit will monitor the system Header Temperature, monitor

all Slave units’ status information and efficiently control all units in order to achieve and maintain

the required BST Setpoint Temperature.

When there is a demand, the Master unit will light off one of the boilers based on the BST

Sequencing selection in the BST menu. As system load increases and the valve position of the

ignited units reach the Next On VP (% valve position), the BST master will light off the next

available unit. A simplified block diagram of multiple Boilers connected to a BST is shown in

Figure 9-1 below.

Figure 10-1. Simplified BST Block Diagram