AERCO BMK 2000DF User Manual

Page 93

Benchmark 1500DF - 2000DF Boilers

CHAPTER 7 – MAINTENANCE

OMM-0098_0A

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

Page 93 of 196

GF-144

Ph.: 800-526-0288

04/01/2014

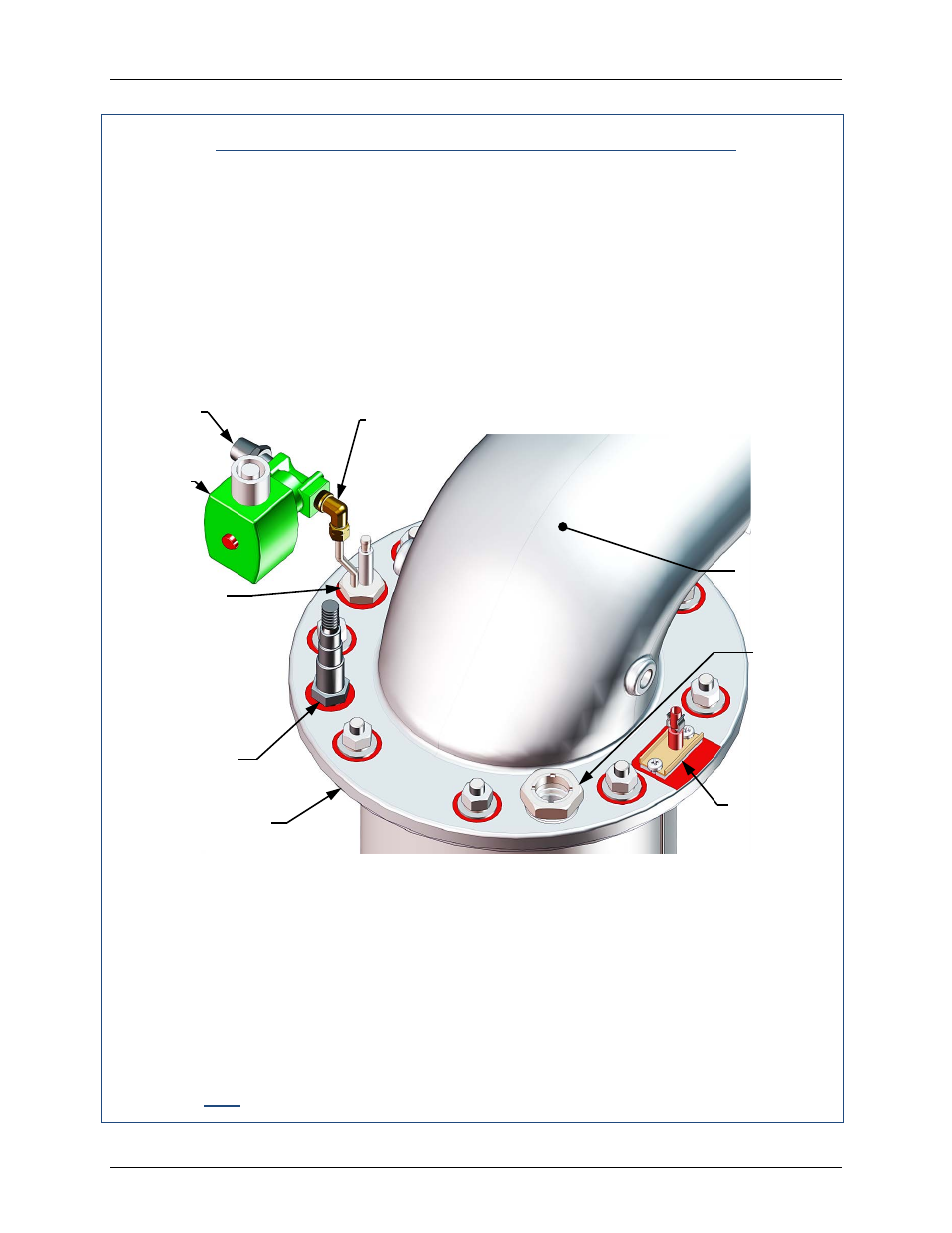

Igniter-Injector Maintenance Procedures – Continued

4.

Refer to the partial exploded view in Figure 7-2. Using a 7/16” open-end wrench,

disconnect the compression nut securing the gas injector tube of the igniter-injector to the

elbow of the staged ignition assembly. Disconnect the staged ignition assembly from the

igniter-injector.

5.

Next, loosen and remove the igniter-injector from the burner plate using a 1" open-end

wrench.

6.

Check the igniter-injector for evidence of erosion or carbon build-up. If there is evidence

of substantial erosion or carbon build-up, the igniter-injector should be replaced. If carbon

build-up is present, clean the component using fine emery cloth. Repeated carbon build-

up is an indication that the combustion settings of the unit should be checked. Refer to

Chapter 4 for combustion calibration procedures.

Figure 7-2: Igniter-Injector & Flame Detector Mounting Details

7.

Next, loosen and remove the igniter-injector from the burner plate using a 1" open-end

wrench.

8.

Check the igniter-injector for evidence of erosion or carbon build-up. If there is evidence

of substantial erosion or carbon build-up, the igniter-injector should be replaced. If carbon

build-up is present, clean the component using fine emery cloth. Repeated carbon build-

up is an indication that the combustion settings of the unit should be checked. Refer to

Chapter 4 for combustion calibration procedures.

9.

Prior to reinstalling the igniter-injector, a high temperature, conductive, anti-seize com-

pound must be applied to the threads.

STAGED

IGNITION

SOLENOID

FLAME

DETECTOR &

GASKET

FLAME

OBSER-

VATION

PORT

INJECTOR-

IGNITOR

ASSY WITH

INDEXING

(CLOCKING)

WASHERS

(0-3 as

needed)

O2 SENSOR

& WASHER

FLEX GAS

HOSE

NIPPLE

COMPRESSION FITTING & ELBOW

BURNER PLATE

FLANGE

BLOWER

PLENUM