3 faults and malfunctions, 1 error messages, 2 malfunctions and their rectification – Metrohm 792 Basic IC User Manual

Page 165

5 Notes – Maintenance – Faults

792 Basic IC

156

5.3

Faults and malfunctions

5.3.1 Error

messages

If any type of malfunction occurs during operation of the 792 Basic IC,

this is shown by error messages in the PC program, which appear ei-

ther in an

error window or in the

SYSTEM STATE

window.

Follow the instructions given in the

error window and close this win-

dow with

.

You will find further details of the error messages of the

SYSTEM STATE

window, their possible causes and the procedure for their rectification in

section 4.3.7.

5.3.2

Malfunctions and their rectification

If difficulties appear with the 792 Basic IC during analyses, their causes

are best investigated in the order

separating column o

o

o

o high-

pressure pump o

o

o

o eluent o

o

o

o connections. Several of the malfunc-

tions which may appear are listed in the following table with details of

possible causes and countermeasures.

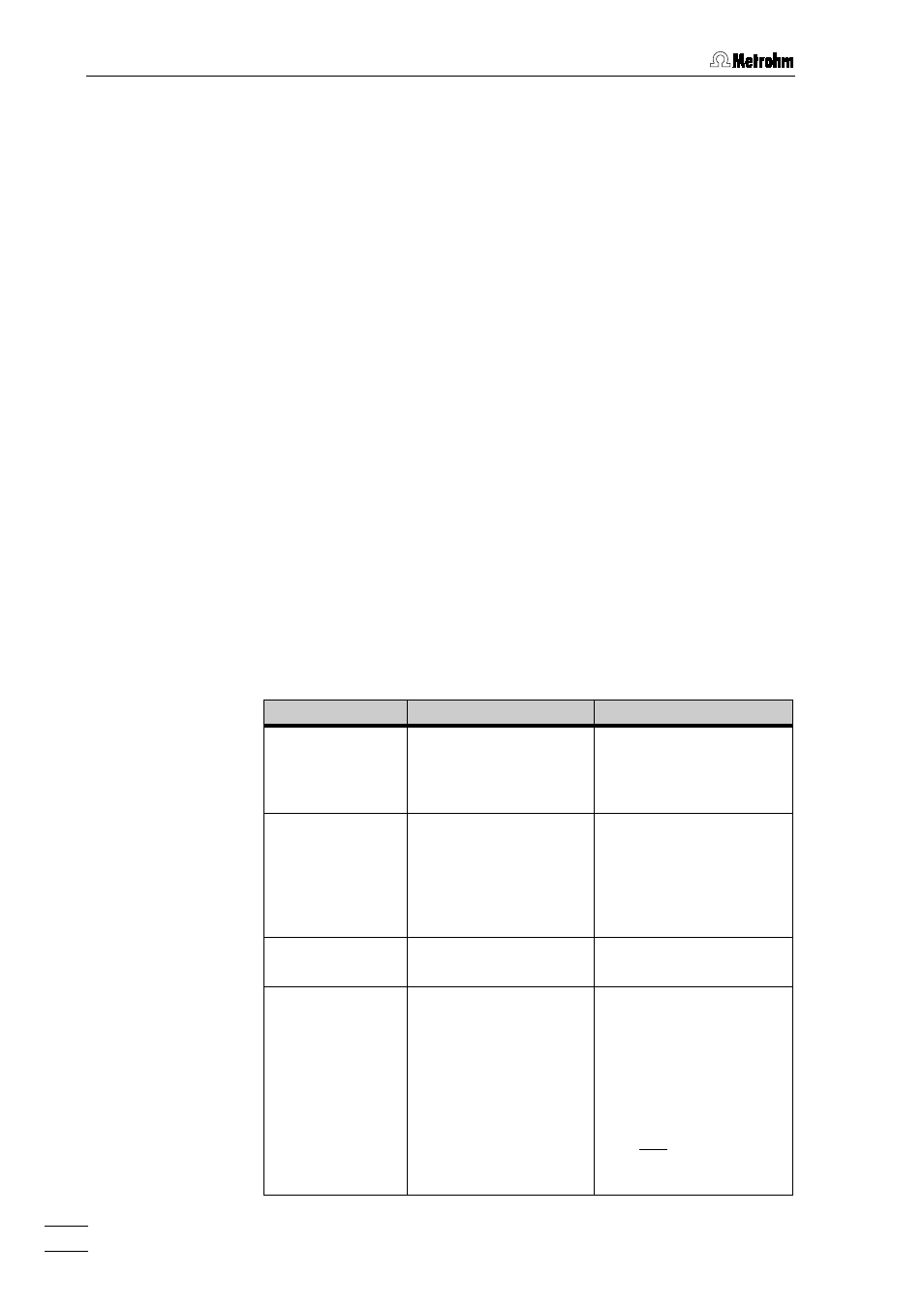

Malfunction

Cause

Rectification

Baseline with high

noise level,

pulsation

x Contaminated pump

valves

x Faulty piston seals

x Clean the valves (see

section 5.1.5)

x Replace the piston seals

(see section 5.1.5)

Drift of the

baseline

x Thermal equilibrium not

yet reached

x Leak in system

x Evaporation of organic

solvent in eluent

x Condition system with

heating switched on

x Check connections and

make leakproof

x Ensure better closure of

eluent supply vessel

Considerable

pressure drop

x Leak in system

x Check connections and

make leakproof

Considerable

pressure rise

x Contamination of the

filter in the 6.2821.100

Filter unit PEEK

x Contamination of the

column inlet filter

x Change of column

packing by injection of

contaminated samples

x Replace the 6.2821.110

Filter (see section 2.3.5)

x Clean or replace

6.2821.020 Steel mesh(es)

x Regenerate column (see

section 5.1.1) or replace

column

Note:

Samples should always

be microfiltered.