Rockwell Automation FactoryTalk Report Expert User Guide User Manual

Page 69

Understanding Report Templates Chapter 5

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

69

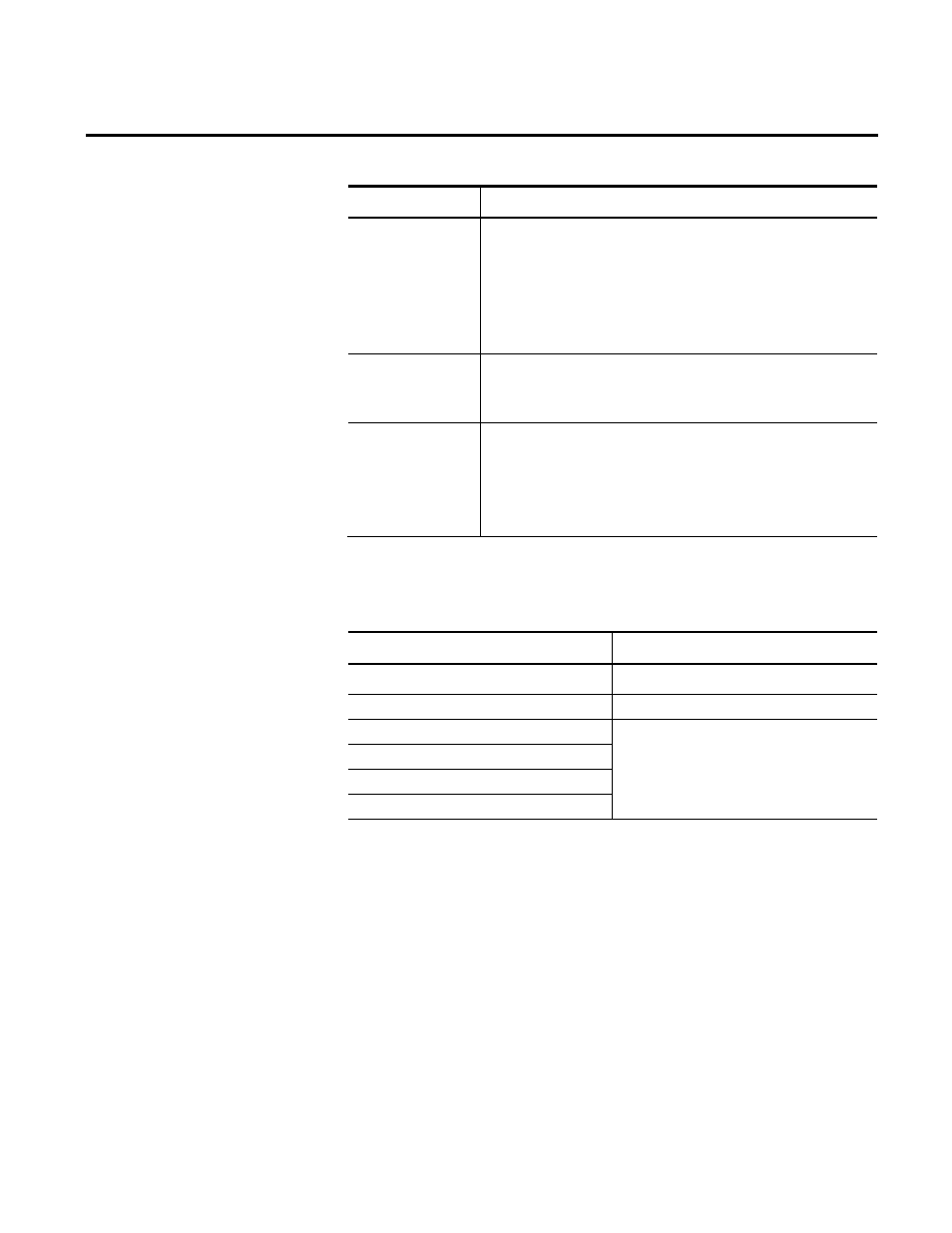

Item

Description

Cycle Time Diff.

The difference, represented by a negative number, between the

ideal amount of time it should take to produce a part and the actual

amount of time it took to produce parts. Better cycle time

differences are indicated by a lower negative number. The

calculation for this field is:

CycleTimeDifference = IdealCycleTime - RealizedCycleTime.

Cycle Time Diff. %

The Cycle Time Difference as a percentage of the Ideal Cycle Time.

The calculation for this field is:

CycleTimeDiff% = -CycleTimeDifference / IdealCycleTime.

Throughput %

The performance of a machine when it is running compared to its

ideal cycle time. The ideal cycle time depends upon the product

being produced and is measured in units of seconds per part. The

calculation for this field is:

Throughput = (TotalParts x IdealCycleTime) / Running Time.

The values of the report template and other report templates to

which the values link using the drillthrough hierarchy:

Click a value in this column:

To display this report template:

Total Parts

Production

Running Time

Uptime

Realized Cycle Time

Throughput (grouped by the next value in

the drillthrough hierarchy)

Cycle Time Diff.

Cycle Time Diff. %

Throughput %

The report template bar charts: a horizontal bar chart showing

Throughput % and a line chart showing Realized vs. Ideal Cycle

Time.

The bar chart fields: