Rockwell Automation FactoryTalk Report Expert User Guide User Manual

Page 61

Understanding Report Templates Chapter 5

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

61

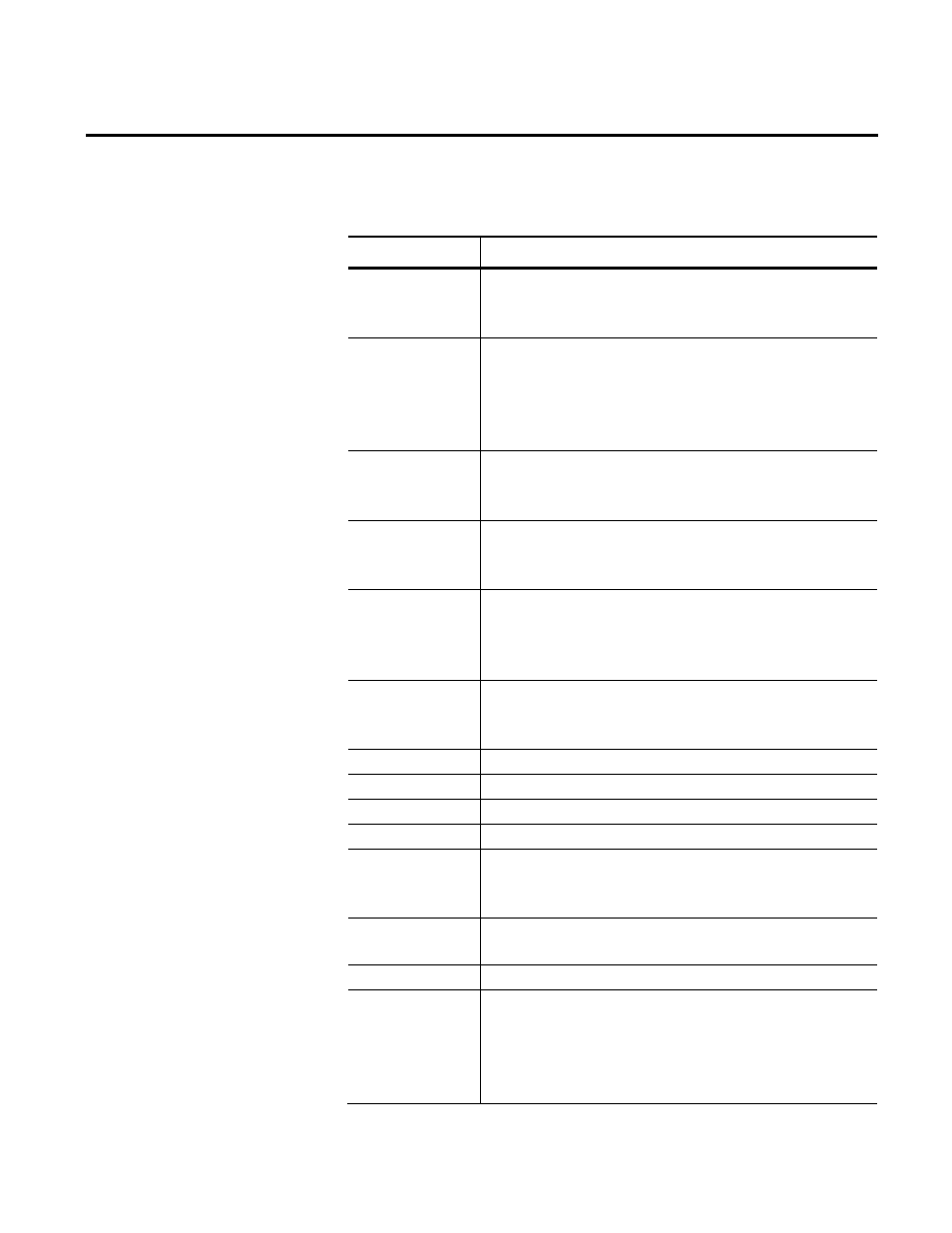

The fields of the report template grid:

Item

Description

Uptime %

The percentage of available time that the machine was actually

running. The calculation for this field is:

Uptime % = RunningTime/AvailableTime.

Throughput %

The performance of a machine when it is running compared to its

ideal cycle time. The ideal cycle time depends upon the product

being produced and is measured in units of seconds per part. The

calculation for this field is:

Throughput = (TotalParts x IdealCycleTime) / Running Time.

Quality %

The percentage of total parts produced that were of good quality.

The calculation for this field is:

Quality % = GoodParts / Total Parts.

OEE %

The product of Uptime, Throughput, and Quality. The calculation for

this field is:

OEE % = Uptime x Throughput x Quality.

Available Time

It may be defined by a schedule or by information from the control

system. Available time may be impacted by scheduled unavailable

time and by the use of Monitored Availability in the work cell's

configuration.

Downtime

The amount of time the machine was available, but was not

running. The calculation for this field is:

DownTime = AvailableTime - RunningTime.

Running Time

The number of seconds the machine was in a running state.

Good Parts

The number of good parts produced.

Scrap Parts

The number of parts rejected due to poor quality.

Total Parts

The total number of parts produced.

Ideal Parts

The total number of parts that could have been produced in the

available time. The calculation for this field is:

IdealParts = AvailableTime / IdealCycleTime.

Scheduled

Unavailable Time

The scheduled unavailable time as defined by the work cell

schedule.

Faults

The number of fault states.

TEEP

(Total Effective Equipment Productivity (or Total Capacity).) A Key

Performance Indicator (KPI) that is similar to the OEE calculation,

but it uses Total Time instead of Available Time in the calculation:

TEEP = (Good Parts * Ideal Cycle Time)/Total Time

TEEP = OEE*(Available Time/Total Time).