Root cause analysis – Rockwell Automation FactoryTalk Report Expert User Guide User Manual

Page 64

Chapter 5 Understanding Report Templates

64

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

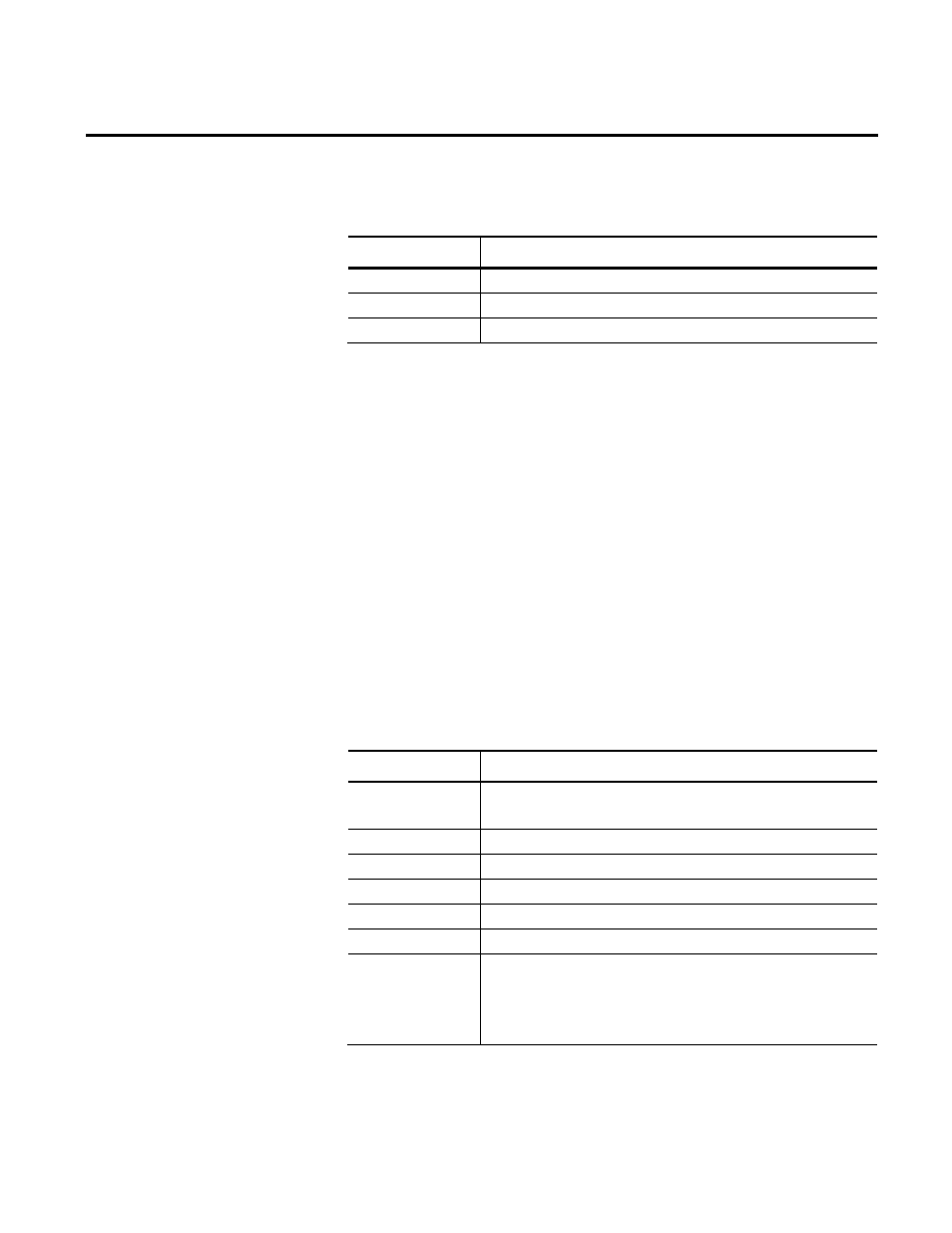

The bar chart fields:

Item

Description

Value

Quality %

X axis grouping

First non-page grouping parameter

Series

Second non-page grouping

Calculations used by Report Expert to obtain values in the resulting

report:

• Quality = GoodParts / TotalParts

The Root Cause Analysis report template consists of a Gantt chart

displaying work cell state occurrences over time. The chart will

display the work cells in the order specified in the Line Order (page

164) tab. Below the Gantt chart for each line is a table of data

showing the same data used in the chart.

Query: State Detail.

The fields of the report template grid:

Item

Description

Work Cell

A level of the plant model (which is constructed by enterprise, site,

area, line, and then work cell).

Shift

The shift during which the data was collected.

Shift Start

The start time of the shift during which the data was collected.

State Name

The machine state. This field is color coded.

Start Time

The date and time that the event or state started.

End Time

The date and time that the event or state ended.

Duration

The length of the event, calculated as the difference between start

time and end time and displayed using the format

HH:MM:SS.mmm. The calculation for this field is:

Duration = End Time - Start Time.

The maximum number of rows in the resulting report: 1000.

Root Cause Analysis