Terminations, Wire wrap terminals, Wrapping tools – Northern Connectors Harting DIN 41 612 Connectors User Manual

Page 33

00

.

27

Gen

er

al

in

fo

rma

tio

n

Terminations

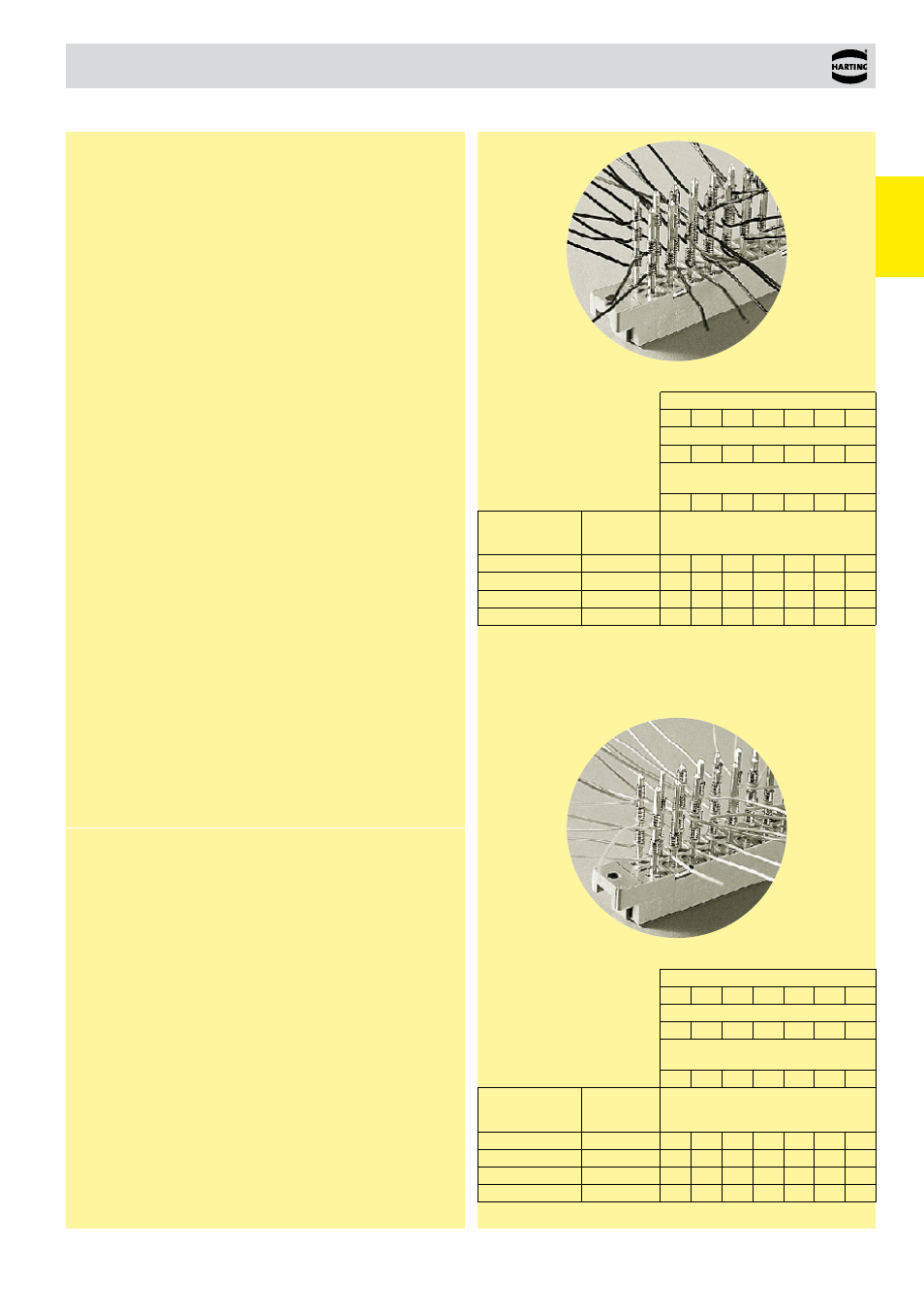

Wire wrap terminals

This technique permits high wiring density and takes over where other

techniques would take up too much real estate. As a result of this

process, there is a great time saving factor and cost per connection is

relatively low when large numbers of connections are to be made.

When wires are correctly wrapped onto a precision manufactured

rectangular post produced to the recommended specifications, one

can state the following:

A low resistance, mechanically strong and highly reliable con-

nection is made which is unaffected by normal climatic or tem-

perature changes.

Production of wrapped connections and associated material are de fined

in DIN EN 60 352-1.

Wrapping techniques

Standard wrap

Only the non-insulated part of the wire is wrapped around the

post. This means that the size of the wrapped connection is

kept to the very minimum.

Modified wrap

The top part of the wrapped connection is made using the

cable conductor as stated above but an extra turn is made at

the bottom. For this turn insulation is also wrapped around the

post to give a great mechanical strength to the joint and also

to provide insulation between adjacent posts.

Wrapping tools

To produce quality wrapped connections one must use a special

wrapping tool, which can be pneumatic, electric or hand operated.

Such tools have interchangeable wrapping heads and sleeves to suit

the particular size of the wrap post being used.

The choice of accessories for these wrapping tools depends from the

wrapping technique, the size of the wrap post itself and the conductor

and insulation diameters of the wire.

The adjacent tables show the maximum amount of wrapped connections

that can be placed on the wire wrap post (in acc. to IEC 60352-1).

Standard wrap

Dimension

of wire wrap

post [mm]

Length

of wire wrap

post [mm]

possible wrap connections

per wrap post

Wire diameter [mm]

0.25 0.32 0.4 0.5 0.65 0.8 1.0

0.7 0.9 1.17 1.27 1.32 1.5 1.78

7 7 6 5 4 4 4

max. allowed wire Ø incl. wire insulation [mm]

min. necessary turns per wrap

connection (for non-insulated wire)

0.6

x

0.6

13

6 5 4 4 4 3 2

0.6

x

0.6

17

8 6 6 5 5 4 3

1

x

1

20

10 7 7 6 6 5 4

1

x

1

22

11 8 7 7 6 5 4

Valid for

standard wrap

Table 00.05

Table 00.06

Modified wrap

Dimension

of wire wrap

post [mm]

Length

of wire wrap

post [mm]

possible wrap connections

per wrap post

Wire diameter [mm]

0.25 0.32 0.4 0.5 0.65 0.8 1,0

0.7 0.9 1.17 1.27 1.32 1.5 1.78

7 7 6 5 4 4 4

max. allowed wire Ø incl. wire insulation [mm]

min. necessary turns per wrap

connection (for non-insulated wire)

0.6

x

0.6

13

4 3 2 2 2 2 1

0.6

x

0.6

17

5 4 3 3 3 2 2

1

x

1

20

6 4 4 3 3 3 2

1

x

1

22

6 5 4 4 4 3 2

Valid for

modified wrap