Terminations, Solder requirements – Northern Connectors Harting DIN 41 612 Connectors User Manual

Page 27

00

.

21

Gen

er

al

in

fo

rma

tio

n

Volume of solder paste

Connector

termination

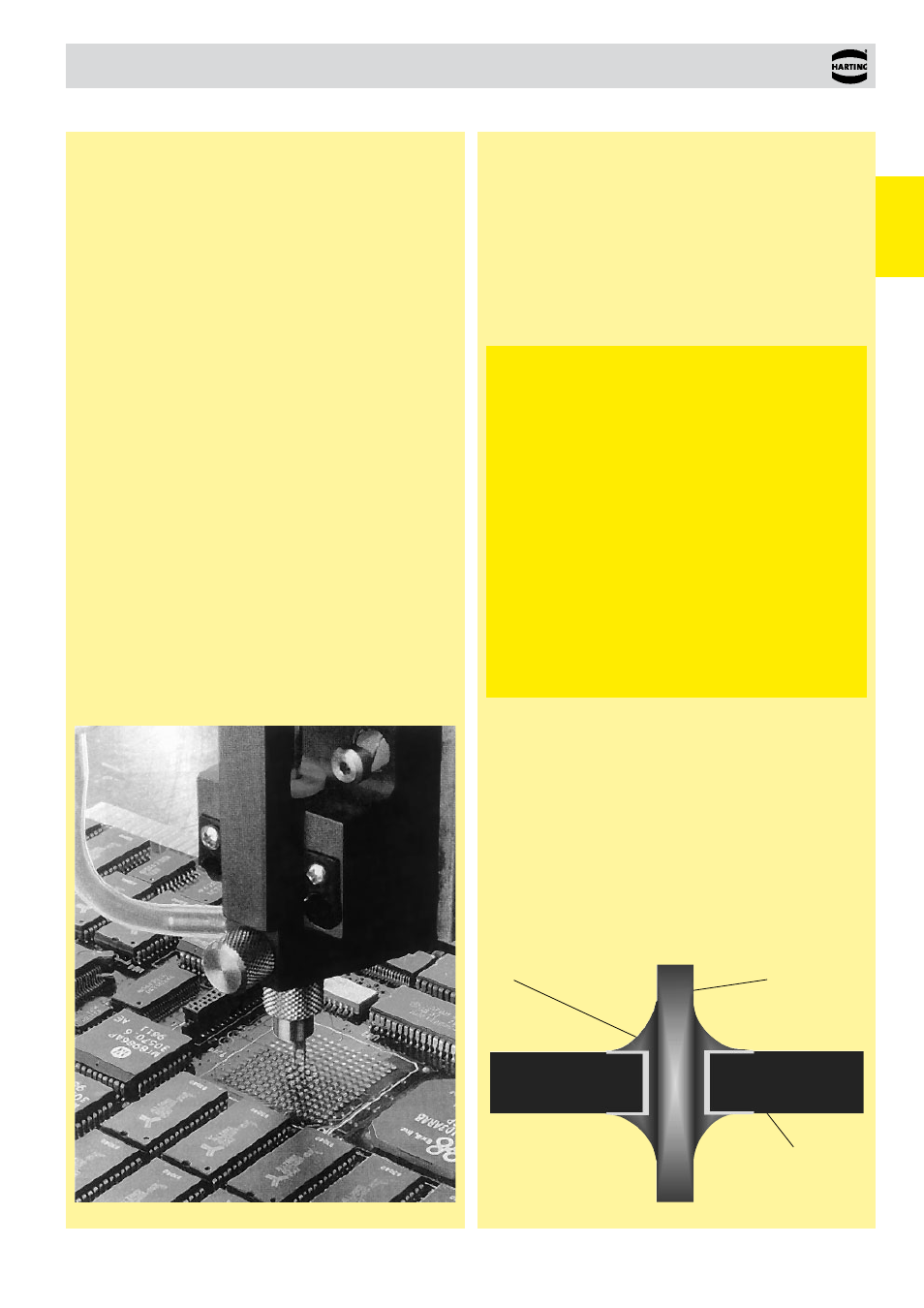

Fig. 3: Dispenser in operation

Fig. 4: Plated through hole with connector termination

pcb

Terminations

Solder requirements

Application of solder paste

Before the components are assembled, solder paste must be

applied to all the solder pads (for connecting surface-mount

components) and the plated through contacts (pcb holes for "Pin

in Hole Intrusive Reflow" insertion). Usually a screen printing

process is used for this purpose. A squeegee moves across

the pcb, which is masked with screens and presses the solder

paste into all unmasked areas. To ensure that the plated through

holes are completely filled, significantly more solder paste must

be applied than traditional solder pads on the pcb surface. The

required quantity can be set exactly via several parameters.

As an alternative to screen printing, the solder paste can be

applied by means of a dispenser. A high- precision robot moves

the dispenser to all required positions on the pcb. The dispensing

method is particularly suitable for small pcb’s or applications

which demand high precision and flexibility in

dispensing

volumes.

Requirements for the solder connection

There are numerous scientific studies dealing with calculation of

the required quantity of solder paste. These studies use various

parameters, e.g. the shrinking factor of the paste during soldering

or the thickness of the screens used for masking the pcb. Since

such calculation methods are complicated to apply, the following

rule of thumb has proved valuable in practice:

V

Paste

= 2(V

H

– V

P

)

in which:

V

Paste

= Required volume of solder paste

V

H

= Volume of the plated through hole

V

P

= Volume of the connector termination

in the hole

Comment: the multiplier “2” compensates for solder paste

shrinkage during soldering. For this purpose, it was

assumed that 50 % of the paste consists of the actual

solder, the other 50 % being soldering aids.

At the beginning of a new production batch, the process

parameters, such as quantity of solder paste and soldering

temperature, can be set by interpreting simple cross-sections

of the soldered connection. A reliable measure for achieving

optimum parameters is the quantity of solder required to fill the

hole. In soldered connections of high quality, the holes are filled

to between 75 % and 100 %.