Repair tooling – Northern Connectors Harting DIN 41 612 Connectors User Manual

Page 206

30

.

10

To

ol

in

g

Repair tooling

Identification

for use with

Part No.

Drawing

Dimensions in mm

rear

I/O shroud

har-bus

®

64

rear

I/O shroud

Type C, 2C

R, 2R

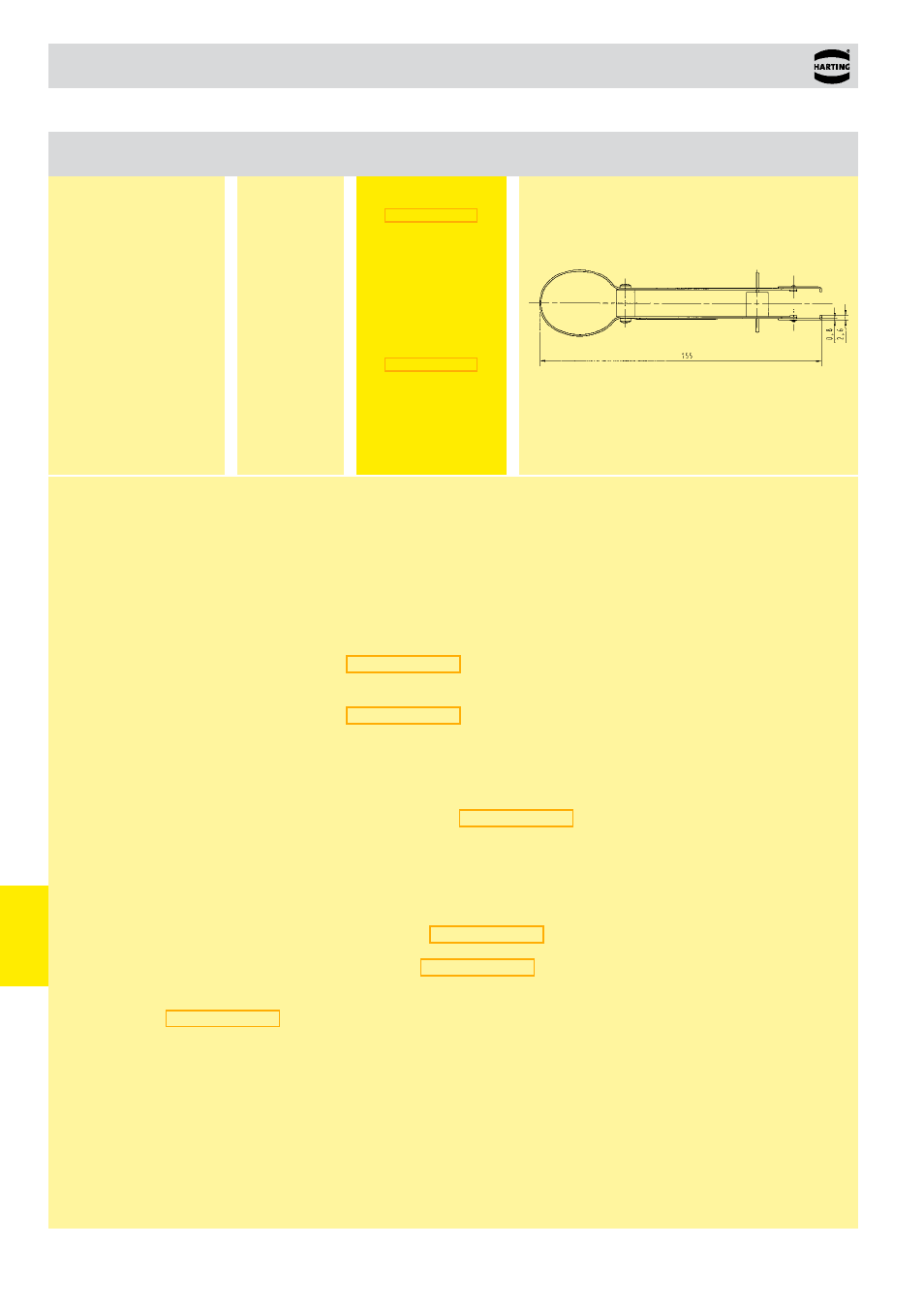

Removal tool

for shroud

Replacement of complete

har-bus

®

64 press-in connectors

Steps in detail

1. Lever up the moulding by using a removal tool

a)

The removal tool with Part No.le for repairing small quantites. It can only be used

if the adjacent components on the pcb are at least 2 mm apart from the moulding of the connector.

b) The removal tool with Part No.le for repairing large quantities. Due to its

design it can also be used if components on the pcb are in close proximity to the moulding of the

connector.

2. Lever up the rear I/O shroud with the remov

termination length.

3. Pull out the female contacts with the press-out tool

a) for 17 mm termination length use Part No.

b) for 5 mm termination length use Part No.

During this process the press-out tool replaces the top tool and the pcb is supported by the support block

(Part No.

- Hummel M40 Circular Power Connectors (20 pages)

- Hummel M27 Circular Connectors (10 pages)

- Hummel M23-Signal - Circular Connectors (32 pages)

- Hummel M23-Power - Circular Connectors (24 pages)

- Hummel M23 RJ45 Circular Connectors (10 pages)

- Hummel M23 Fast Ethernet PoE Circular Connectors (12 pages)

- Hummel M16 Circular Connectors (26 pages)

- Hummel M16 Stainless Steel Connector Housings (10 pages)

- Hirschmann NR-Series Circular Connectors (23 pages)

- Hirschmann CM-Series Plastic Screw Locking Connectors (MIL-C-5015) (11 pages)

- Hirschmann CA-Series Plastic Screw Locking Circular Connectors (2 pages)

- Normek PCB Connectors (2 pages)

- Harting Har-flexicon Connectors (34 pages)

- Harting Har-flex PCB Connectors (17 pages)

- Harting D-sub Connectors, Housings & Accessories (203 pages)

- D-Sub Plastic Hoods (10 pages)

- D-Sub Metalized Plastic Hoods (8 pages)

- D-Sub Full Metal Hoods (22 pages)

- Conec D-Sub Hoods & Accessories (54 pages)

- Lumberg Automation M12 Single-Ended Cordsets (2 pages)

- Lumberg Automation M12 Field-Attachable Cable Connectors (2 pages)

- Mennekes Plugs - IP67 (1 page)

- Mennekes Wall Mounted Inlet (1 page)

- Souriau UT0 Metal Circular Connectors (12 pages)

- Souriau UT0W Metal High Density Circular Connectors (12 pages)

- Souriau UTG Plastic Circular Connectors with Metal Coupling (32 pages)

- Souriau UTL Series Push-Pull Connectors (60 pages)

- Souriau UTP Plastic Circular Connectors (24 pages)

- Souriau UTS Hi Seal Plastic Circular Waterproof Connectors (8 pages)

- Souriau UTS Screw Termination' Plastic Circular Waterproof Connectors (4 pages)

- Souriau UTS Plastic Circular Waterproof Connectors (5 pages)

- Souriau 840 Series Metal Circular Connectors (10 pages)

- Souriau MBG Plastic Circular Connectors (24 pages)

- Souriau Mixed Power / Signal Circular Connectors (5 pages)

- Souriau Overmoulded Cable Assemblies (8 pages)

- Souriau VGE1 / FER1 Ruggedized Metal MIL-DTL-5015 & VG 95234 Connectors (1 page)

- Souriau VGE1 / FER1 Ruggedized Metal MIL-DTL-5015 & VG 95234 Connectors (31 pages)

- Mennekes Panel Mounted Sockets (5 pages)

- Mennekes Panel Mounted Inlet (1 page)

- Mennekes Connectors - IP67 (1 page)

- Mennekes Connectors - IP44 (1 page)

- Lumberg Automation M8 Single-Ended Cordsets (2 pages)

- Alpha Wire XTRA-GUARD Performance Cable (94 pages)

- Alpha Wire Hook-Up Wire (48 pages)

- Alpha Wire FIT Heat-Shrink Tubing (34 pages)