Cpm press-in machines – Northern Connectors Harting DIN 41 612 Connectors User Manual

Page 211

30

.

15

To

ol

in

g

CPM press-in machines

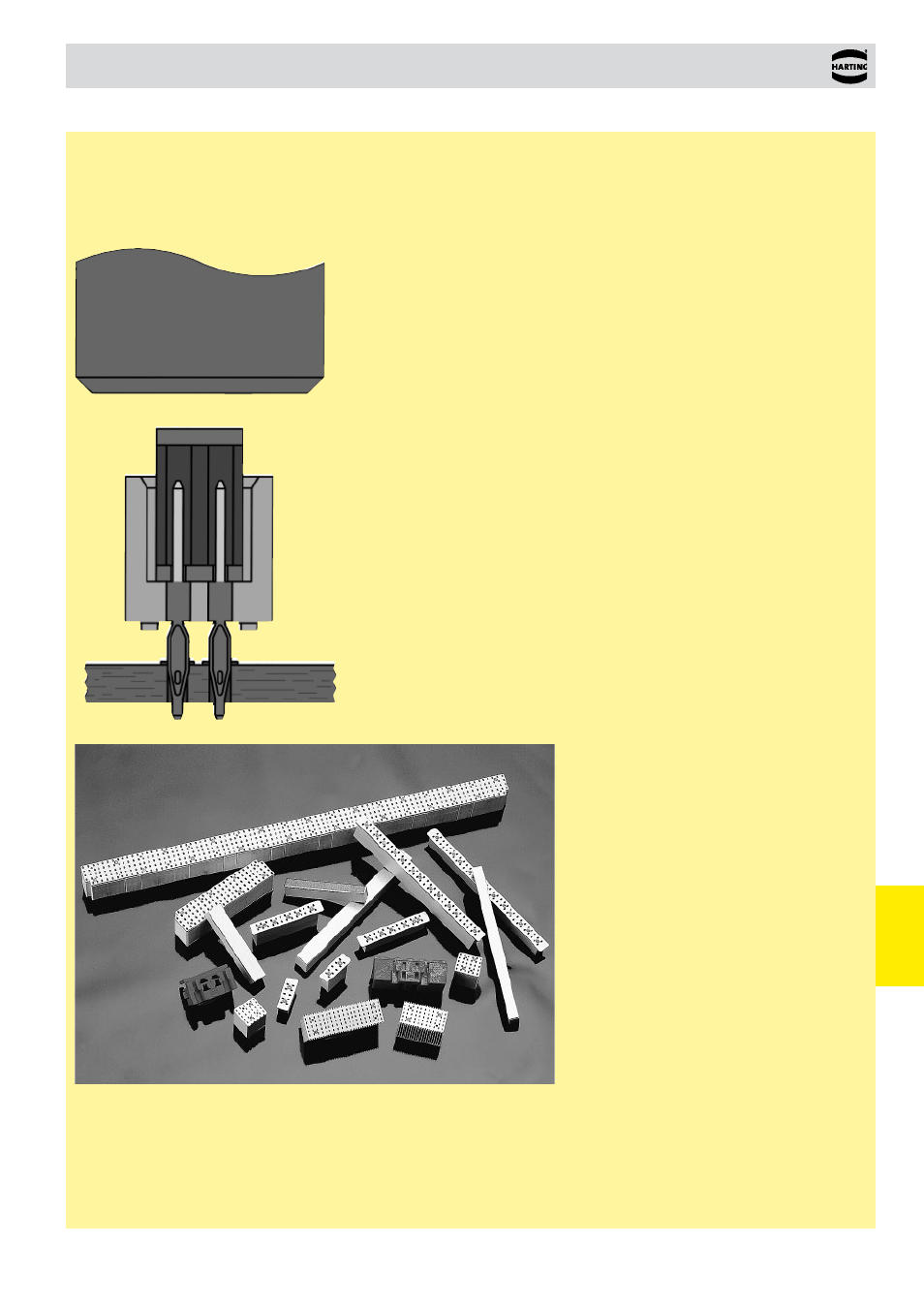

Today nearly all female connectors are designed for flat rock tooling. For every type of male connector specific

tooling and a high degree of X-Y-process accuracy is required. Therefore HARTING offers press-in insert blocks

that transfer all well known assembling advantages from female connectors to male headers.

Advantages of press inserts

Robust tooling

No lateral force to pcb hole

No abrasion of the contact mating surface by the press tool

HARTING has already developed press-

in inserts for all major male connector

families on 2.54 mm, 2.5 mm and 2 mm

pitches.

Inserts for any other special components

can be developed on request.

The additional process for inserting and

removing the press-in inserts can be

efficiently done with the insertion removal

station. This station removes all press-

in inserts with a magnetic plate in one

operation and inserts them into the next

pre-assembled pcb with the necessary

precision. (Principle see page 30.14).

The cycle time for loading all headers is between 4 and 6 seconds, independent from the amount of press-in

inserts.

To load the inserts automatically means also that connectors assembled in a wrong way will be recognised and

errors consequently prevented.