Terminations, Press-in technology – Northern Connectors Harting DIN 41 612 Connectors User Manual

Page 29

00

.

23

Gen

er

al

in

fo

rma

tio

n

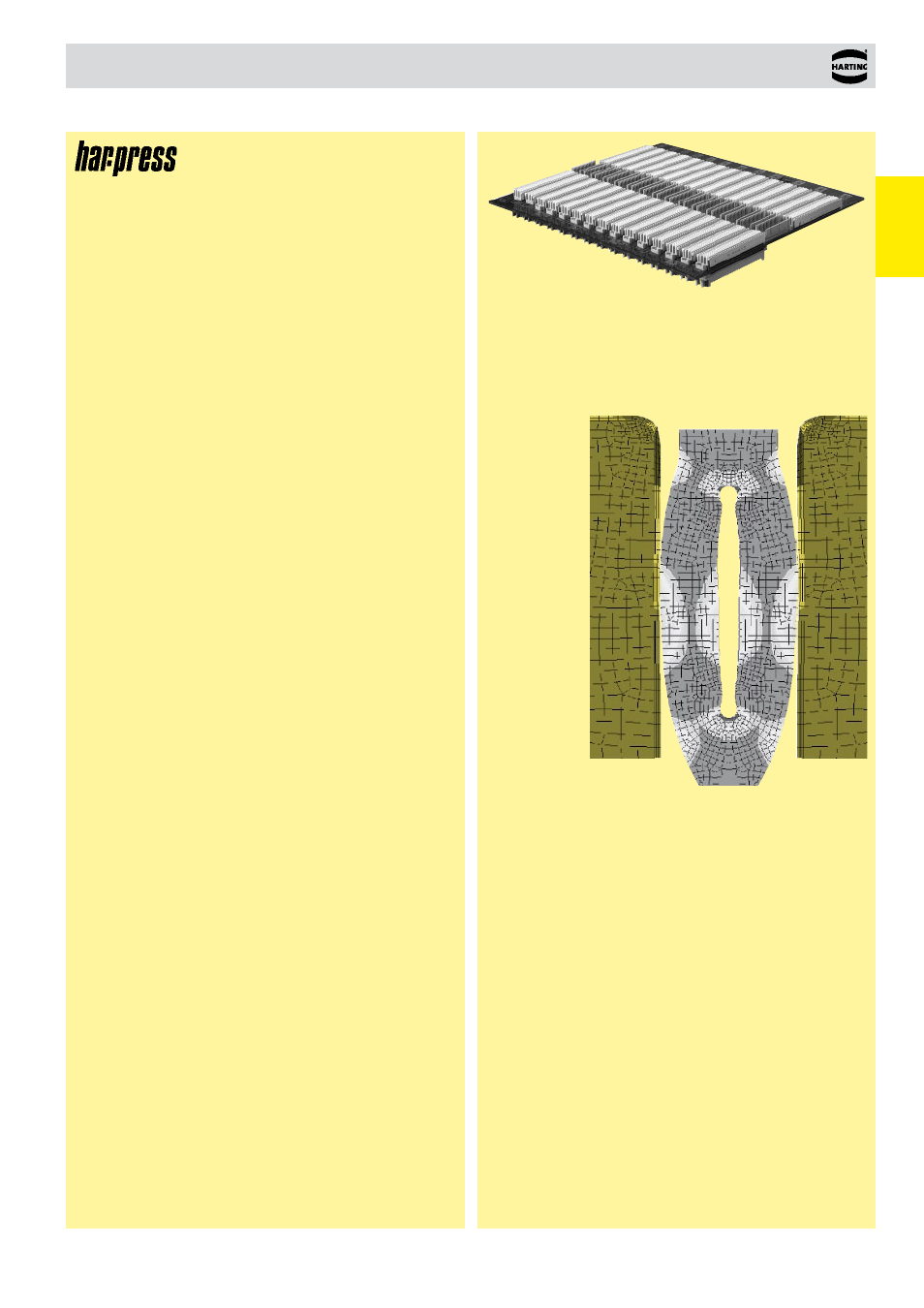

bus board with

press-in connectors

FEM simulation

of the needle eye

press-in zone

Terminations

Press-in technology

Solderless termination for connectors has proven to be reliable for

decades. Today the use of press-in connectors encompasses all

fields of electrical and electronical applications.

Pressing of electrical components, mainly connectors, is characte-

rised through the matching of the connector pin and the plated

through hole of the pcb. Whereas the desired electrical characteri-

stics can be attained relatively independant from the design of the

press-in zone, the mechanical characteristics of the press-in zone

are crucial for the reliable assembly of connectors where pcb's

have different surfaces.

Although the scope of requirements at the press-in process is

generally defined in time-tested specifications, the novel press-in

zones should offer an optimal handling and a reliable termination.

Essentially, this is guaranteed through the design of the press-in

zone and the meticulous observance of tolerances. HARTING has

been using FEM simulations for the calculation and optimisation of

press-in zones for a long period of time. This expertise allows us to

simulate various pcb configurations very accurate.

Benefits of the press-in technology

●

Thermal shocks associated with the soldering process and the

risk of the board malfunction are avoided.

●

No need for the subsequent cleaning of the assembled pcb’s

●

Additional wrap connections are made possible by using

connectors with long pins

●

Unlimited and efficient processing of partially gold-plated pins

for rear I/O - manual soldering is no longer necessary!