Specifications, assembly instructions, Design of connectors, Building up card frame systems – Northern Connectors Harting DIN 41 612 Connectors User Manual

Page 13: Complementary components

00

.

07

Gen

er

al

in

fo

rma

tio

n

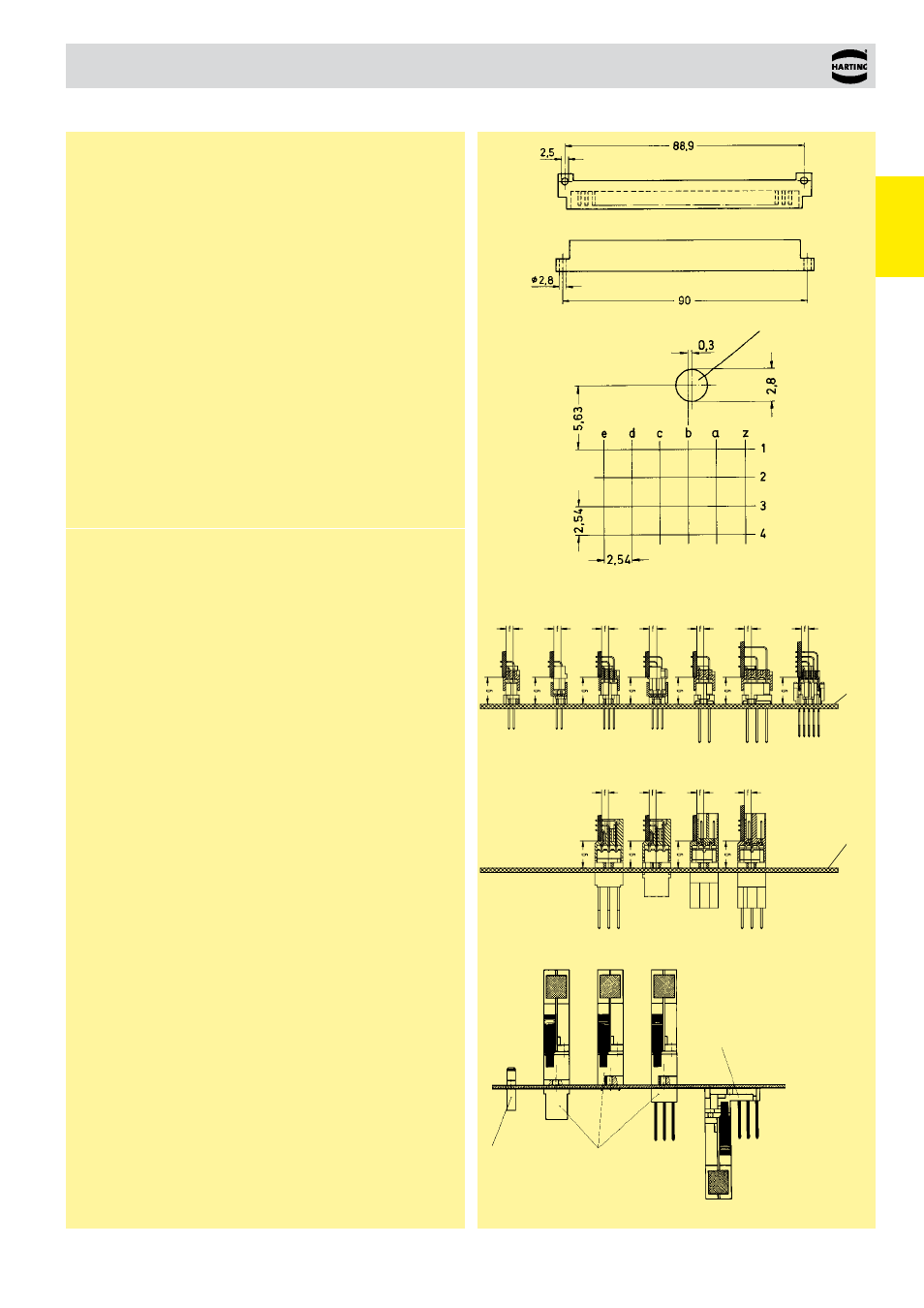

Specifications, assembly instructions

Mounting hole

Type F

Interface connector U

Type F

Distributor

Type F

Interface connector I

Contact spacing

g = 12.4 -14.2

f = 3.55

g = 12.4 -14.2

f = 3.55

Design of connectors

●

Standard fixing arrangement

●

Standard positions for pcb´s and connectors provide a modular

system in the card frame and a standard front panel system.

●

Standard wiring matrix on the connection side for female connectors

built up on a 2.54 mm (0.1" centres) grid. (This facilitates automatic

wiring).

●

Printed circuit boards with standard dimensions 100 x 160

resp. 233.4 x 160 mm as set out in DIN EN 60 297-3 standard sizes

3 U and 6 U.

Building up card frame systems

In the basic frame unit according to DIN EN 60 297-3 pcb’s are

insert ed from the front and make contact with the connectors fitted

to the back. This basic arrangement gives the following advantages:

●

When using conventional connectors on the back of the card frames,

space is left above, below and in the middle along the hor izontal

line of the frame which can be used to fit extra connectors for cross

connection or making plug connections by means of flying lead

connectors.

●

Using the HARTING system one can also connect flying lead

connectors onto the front of the frame or even onto the inside of the

back of the frame. This means that external equipment can easily

be monitored, controlled or tested from the card frame itself.

Complementary components

All connectors can be supplied with a complete range of accessories.

These can be fitted above or below the wiring plane on the back of

the card frame or on the front of the card frame. These connectors

and accessories provide a complete connector system suitable for

commonly used wiring techniques.

●

The flying lead connector consists of a connector with crimp or

solder contacts and a shell housing. The flying lead connector is

latch ed or retained in position using screw fixings and is compatible

with a corresponding male connector and interface connectors I

and U.

●

Fixing brackets prohibit the withdrawal of the pcb when a flying lead

connector is used on the front side of the card frame.

●

The interface connector I has blade contacts on the plug side and

solder pins, wrap posts or crimp terminals on the termination side.

It replaces the female connector type F fitted into the frame and

allows interfacing to the internal wiring with the help of the flying

lead connector on the back of the card frame unit.

●

On the one plane the interface connector U has male contacts that

are compatible with the flying lead connector. On the other plane

it has wrap posts for interfacing to the internal wiring of the card

frame. It can be mounted on the back of the card frame above

or below other connectors arranged upright. Its wrap posts follow

the same pitch as other connectors therefore allowing automated

wiring. By using the U connector with the flying lead connector

plug-in connections between the card frame and the peripheral

equipment/ out lying stations are made easy.

Type

B Q C R D E har-bus 64

Type

F H MH

Mounting

level

Mounting

level