Hand bench presses / pneumatic presses, Cpm press-in machines – Northern Connectors Harting DIN 41 612 Connectors User Manual

Page 208

30

.

12

F

To

ol

in

g

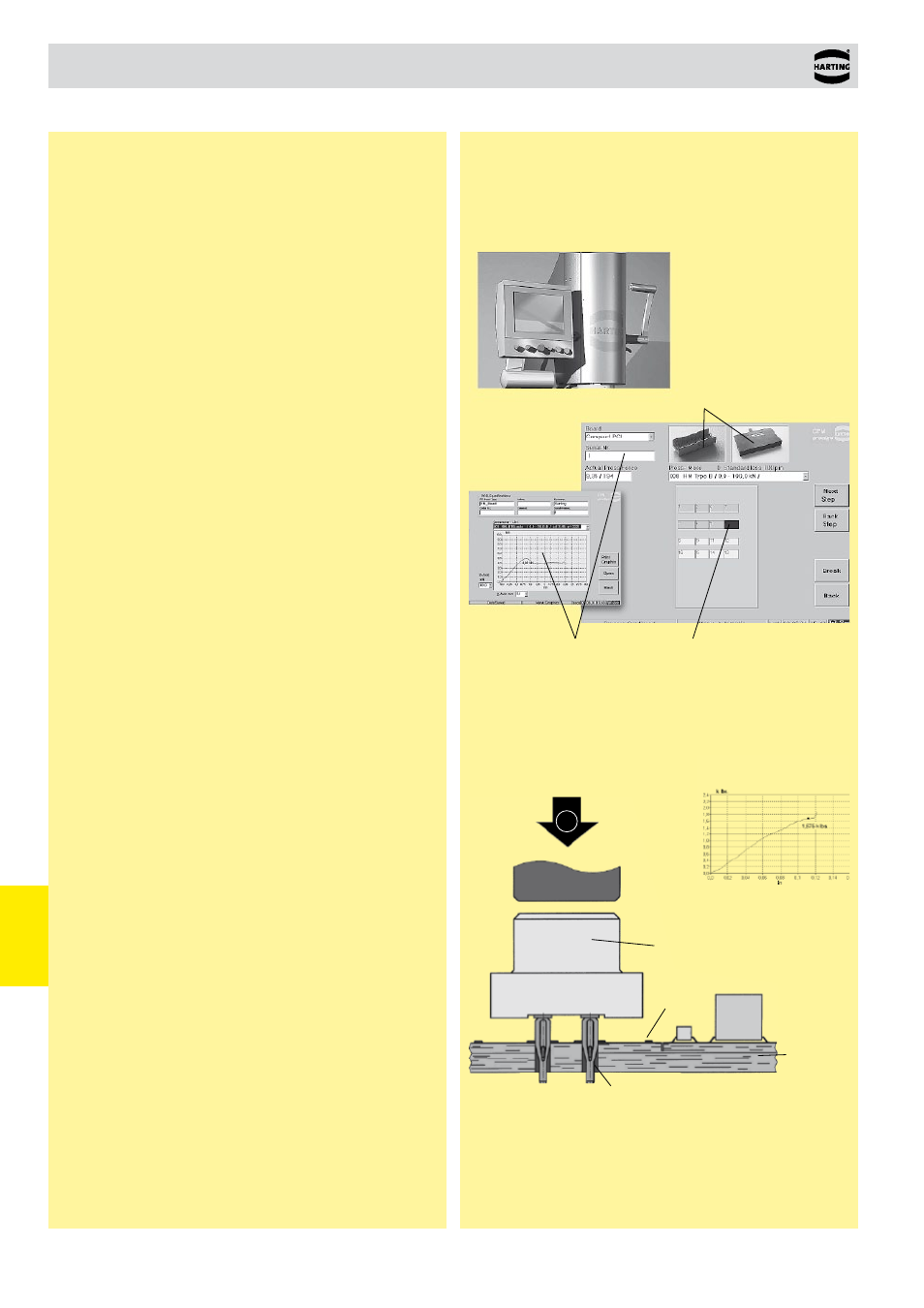

CPM press-in machines

The

CPM prestige press-in machine

with a graphical user interface

The

CPM prestige is a consequential develop-

ment of the successful CPM 2001 press-in

machines. The excellent design, supported by a

wide range of tools presents a convenient, easy

and comfortable way of processing backplanes

and daughtercards. The machine is fully

programmable and is supplied with a graphical

user interface for control and visualisation of the

complete process. The use of a microprocessor

control allows the recognition and storage

of

different component heights, so that the

pressing-in of different components is initiated

simultane ously with only one button. The user-

friendly touch-screen guides the user through

the menu-orientated process controls.

The visualisation of the entire press-in process

(the position of the connector, press-in forces

etc.) allows the rapid recognition and eradication

of the possible error sources. With the addition of

a barcode reader (1D and 2D)

1)

the parameters

of every pcb layout can be stored, recalled and

loaded into the automated press-in programme.

The extensive operation monitor functions

simplify the service and support of the machine.

The machine employs the automatic switch-

off

system “autosense”, known worldwide for

its reliability. The different connector types and

the

tolerances of the pcb are automatically

recognised and taken into consideration at the

press-in operation, thus maximising the process

security.

Connector

type

Pcb

surface

Board

thickness

Force vs. distance curve

Hole diameter

Shown are the four most considerable influences of the press-in

process.

Visual guiding system

via touch monitor

Real photos of connectors

and tools

Process data

Layout with current

position highlighted

1)

optional