Terminations, Press-in technology – Northern Connectors Harting DIN 41 612 Connectors User Manual

Page 30

00

.

24

Gen

er

al

in

fo

rma

tio

n

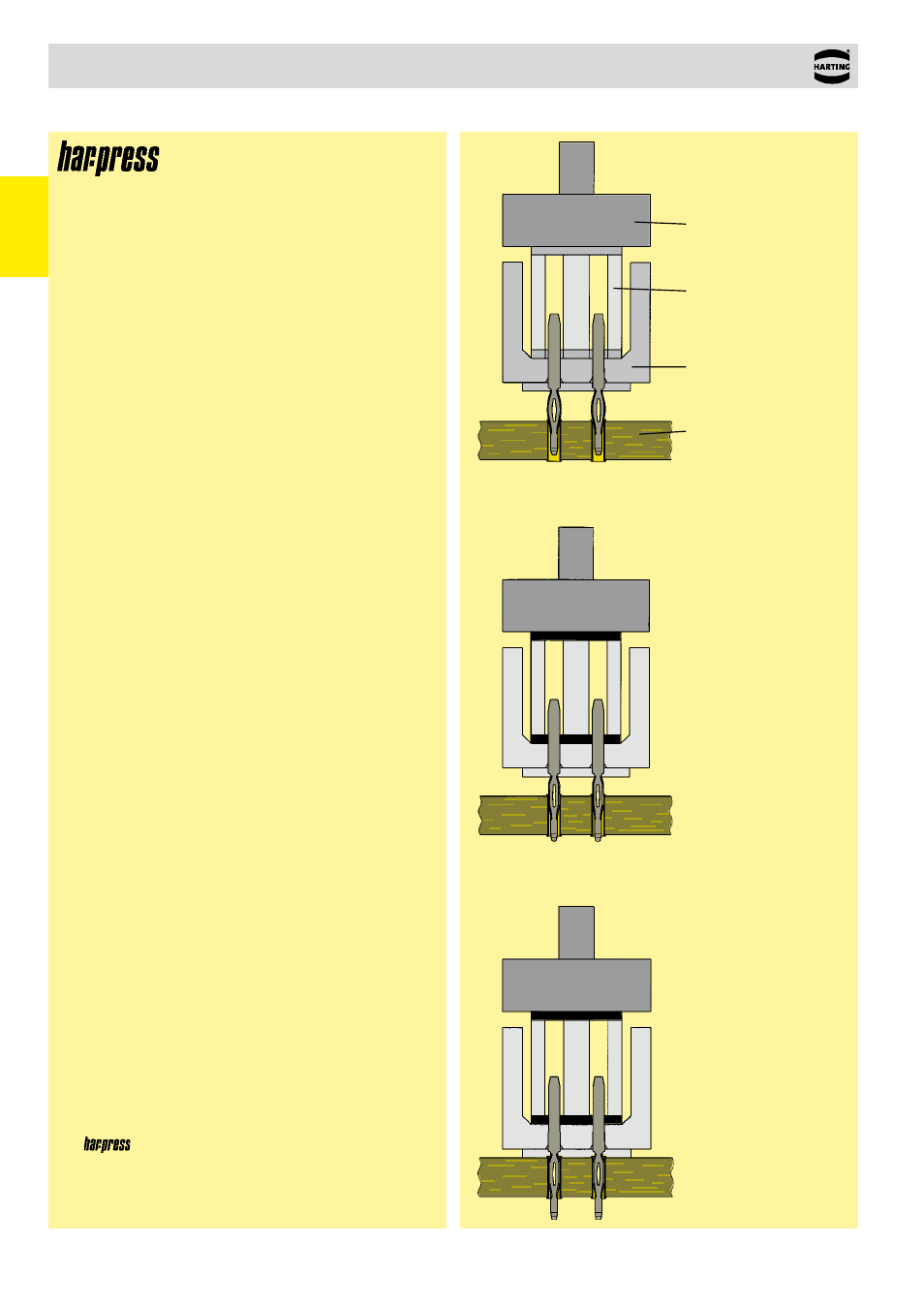

Press-in technology

The processing of press-in connectors can be divided into 3 pha-

ses, containing both mechanical and metallurgical operations:

1. Centering and placing of the termination pins

The centering of connectors before pressing is important in

order to prevent damage to the pcb and the termination pins.

Centering can be omitted when connectors are pressed using

a flat rock die.

HARTING offers insert blocks for male connectors to make

the centering of connectors unnecessary.

2.

Pressing in the pins

In the press-in process the insertion force is continuously

transformed into compression force. The resulting friction

frees the contacting bars of insulating films. Superfluous

plating (tin) is transferred within the plated through hole. A

gas-tight connection of fresh non-oxidised metal surfaces is

obtained.

3.

Obtaining the final position

The press-in operation should be terminated as soon as

the connector obtains its final position on the pcb to avoid

unnecessary compressive stress. The press-in machines

of HARTING feature automatic termination of the press-

in operation independant of pcb thickness and surface

properties.

The entire dynamic press-in process is characterised through

changes of the press-in force that can be statistically evaluated.

HARTING records the changes of force with the help of special

software. This is an important step towards permanent process

control and documented manufacturing data.

The

-zone is based on the industry renowned needle eye

technology. Its special design allows for compensation of tolerances

of pcb surface properties (eg. superfluous tin plating). The excessive

material is displaced within the plated through hole, whereby a gas-

tight and corrosion resistant electrical connection is assured.

Phase 2

Phase 3

Terminations

Press die

(Flat rock)

Connector

Multilayer

pcb

Insert block

Phase 1