Cpm press-in machines, Quality control of press-in termination – Northern Connectors Harting DIN 41 612 Connectors User Manual

Page 209

30

.

13

CPM prestige

To

ol

in

g

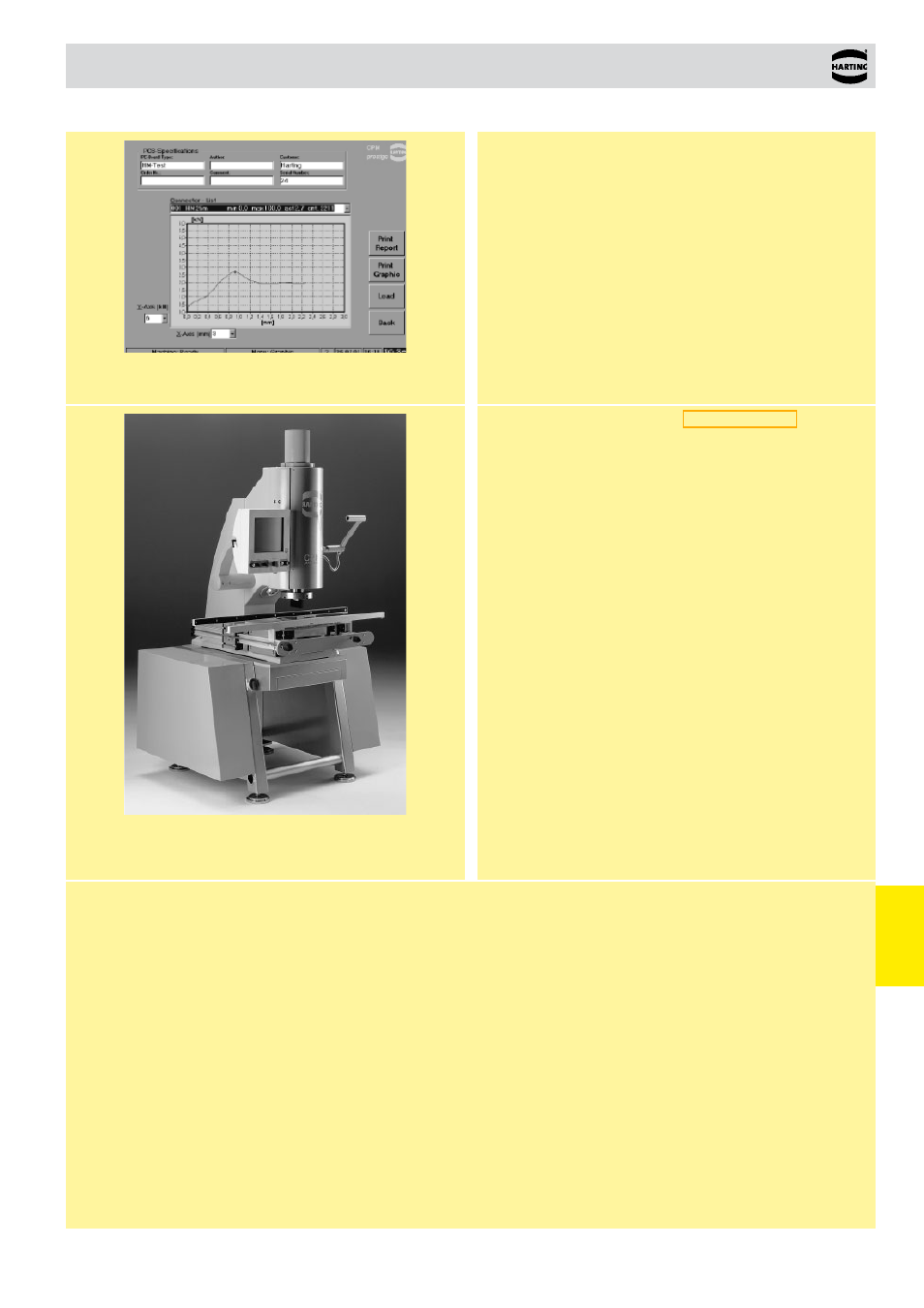

CPM press-in machines

Quality control of press-in termination

The press-in force correlates with the diameter of the

plated through hole and with the friction coefficient of

the surface; therefore it can be used for a continuous

monitoring of the process.

The retention force, as an indirect measure of the

normal force, serves to qualify the process or random

tests.

Built-in features:

●

Guiding rails (carbon/spring-loaded) for the secure positioning of the pcb

●

Touch-screen and Industrial PC with UPS (uninterruptable power supply)

●

Barcode reader for management ease of press-in programs

●

All dimensions allow an easy integration into production lines

Process monitoring

and quality assurance:

●

Touch screen interface with graphical and verbal menus for all machine functions

●

Autosense: automated press-in interruption at incorrect press-in forces

●

Storage and validation of all press-in parameters via quality assurance software

(press-in force tolerances)

●

Continuous high-precision measurement and recording of press-in forces and

distances

●

Remote determination of errors and maintenance

●

High flexibility through a modular tool range

Options:

●

Rotatable tool changer

●

Insertion removal station

Part No.

Technical characteristics

Drive

electro-mechanical,

servo

Press-in force

100 kN

max. pcb dimensions

600 x 1000 mm

Floor space

1200 x 1150 mm

Weight

980 kg

Power supply

208 / 380 / 400 / 415 V

Consumption

< 1 kW

Colour

on request

CPM prestige

(incl. PC, control software, barcode reader, keyboard,

touch screen)