Technical characteristics types f, f9, fm and 2f – Northern Connectors Harting DIN 41 612 Connectors User Manual

Page 126

03

.

26

DIN

P

ow

er

up t

o 6 A

Technical characteristics

Types F, F9, FM and 2F

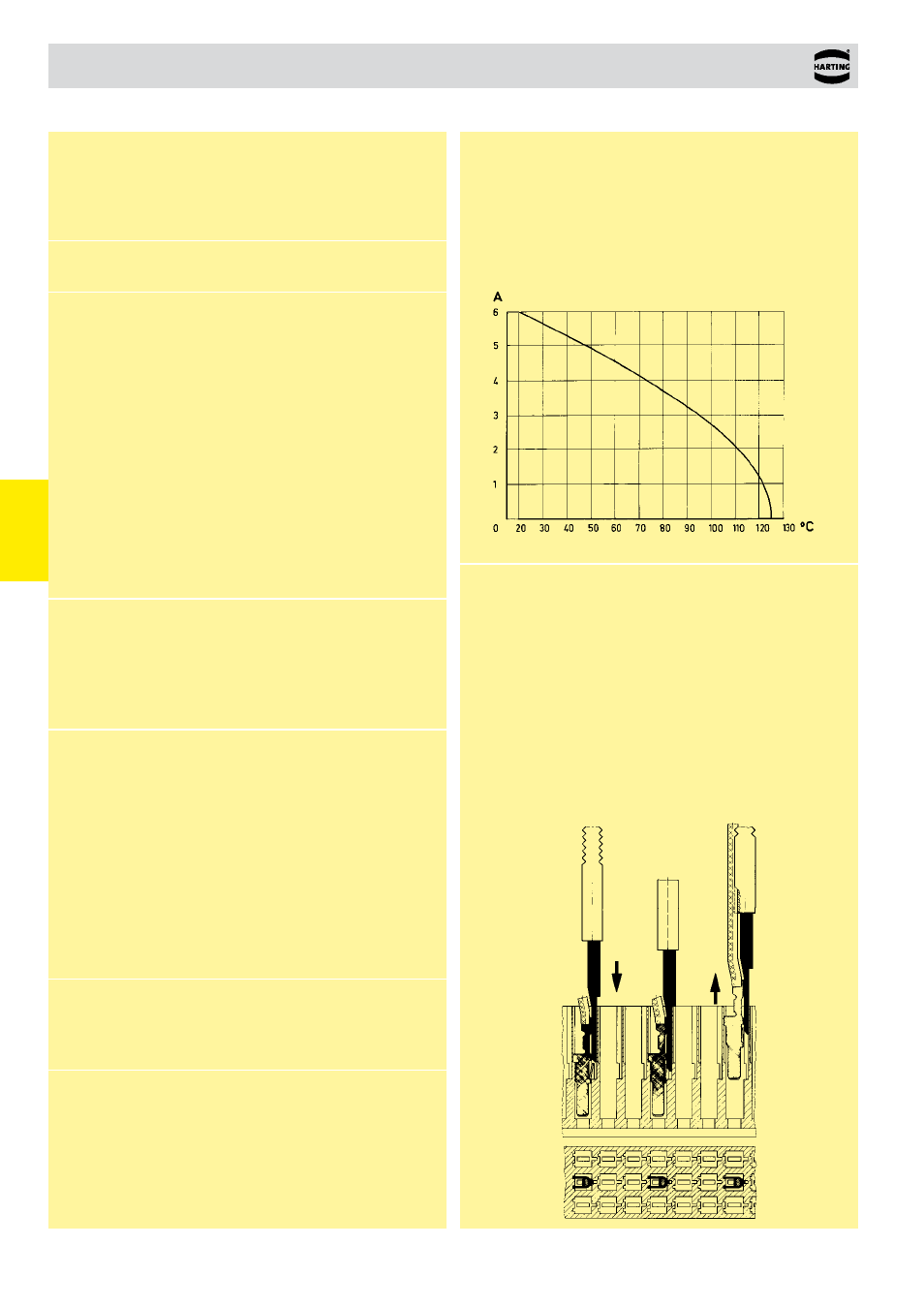

Current carrying capacity

The current carrying capacity is limited by maximum temperature of

materials for inserts and contacts including terminals . The current

capacity curve is valid for continuous, non interrupted current loaded

contacts of connectors when simultaneous power on all contacts is

given, without exceeding the maximum temperature .

Control and test procedures according to DIN IEC 60 512

Fitting the crimp contacts

After crimping the wires onto the contacts with the help of a crimping

tool or an automatic crimping machine the contacts should be correctly

oriented and inserted into the cavities of the connector moulding in the

required configuration . They snap into position and are firmly held in

place . A light pull on the wire assures the correct tensile strength of

the contact . When using stranded wires with a gauge below 0 .37 mm²

an insertion tool is necessary .

Removing the crimp contacts

The removal tool is inserted into a slot on the termination side of the

respective crimp cavity . This action compresses the contact retaining

spring therefore the contact can then be easily withdrawn using a

light pull on the wire . This action will cause no damage to the contact/

wire which can be repositioned/refitted as necessary . The drawing

demonstrates the crimp removal procedure (max . 5x) .

W

or

king current

Ambient temperature

Removal tool

Number of contacts

Type F

48, 32

Type FM

45

Type 2F

max . 24

Type F9

max . 9

Contact spacing (mm)

5 .08

Working current

6 A max .

see current carrying capacity chart

Clearance

≥ 1 .6 mm

Creepage

≥ 3 .0 mm

Working voltage

The working voltage also depends

according to the safety

on the clearance and creepage

regulations of the equipment

dimensions on the pcb itself

Explanations see chapter 00

and the associated wiring

Test voltage U

r .m .s .

1 .55 kV (contact-contact)

2 .5 kV (contact-ground)

Contact resistance

≤ 15 mΩ

Insulation resistance

≥ 10

12

Ω for standard articles

≥ 10

11

Ω for special NFF articles

(with part-no . ending 222)

Temperature range

– 55 °C … + 125 °C

The higher temperature limit

– 40 °C … + 105 °C

includes the local ambient

for press-in connector

and heating effects of the

contacts under load

During reflow soldering

max . + 240 °C for 15 s

for SMC connectors

Electrical termination

Solder pins for pcb

connections Ø 1 ± 0 .1 mm

according to IEC 60 326-3

Wrap posts 1 x 1 mm

diagonal 1 .34-1 .45 mm

Crimp terminal 0 .09-1 .5 mm²

Angled solder pins 1 x 1 mm

for pcb connections

Ø 1 .6 ± 0 .1 mm

Solder lugs

Compliant press-in

terminations

pcb thickness

≥ 1 .6 mm

Recommended pcb holes

See recommendation page 00 .25

for press-in technology

in acc . to EN 60 352-5

Insertion and withdrawal force

48 way ≤ 75 N

45 way ≤ 70 N

32 way ≤ 50 N

24 way ≤ 37 N

Materials

Mouldings

Thermoplastic resin,

glass-fibre filled, UL 94-V0

Contacts

Copper alloy

Contact surface

Contact zone

Selectively plated according

to performance level

1)

1)

Explanation of performance levels see chapter 00

Mating conditions

see chapter 00

Coding systems

see chapter 00

Mounting clips

see chapter 00