Terminations, Recommended configuration of plated through holes – Northern Connectors Harting DIN 41 612 Connectors User Manual

Page 31

00

.

25

M 29:1

M 58:1

M 58:1

II

I

I

II

M 29:1

M 58:1

M 58:1

II

I

I

II

M 29:1

M 58:1

M 58:1

II

I

I

II

Gen

er

al

in

fo

rma

tio

n

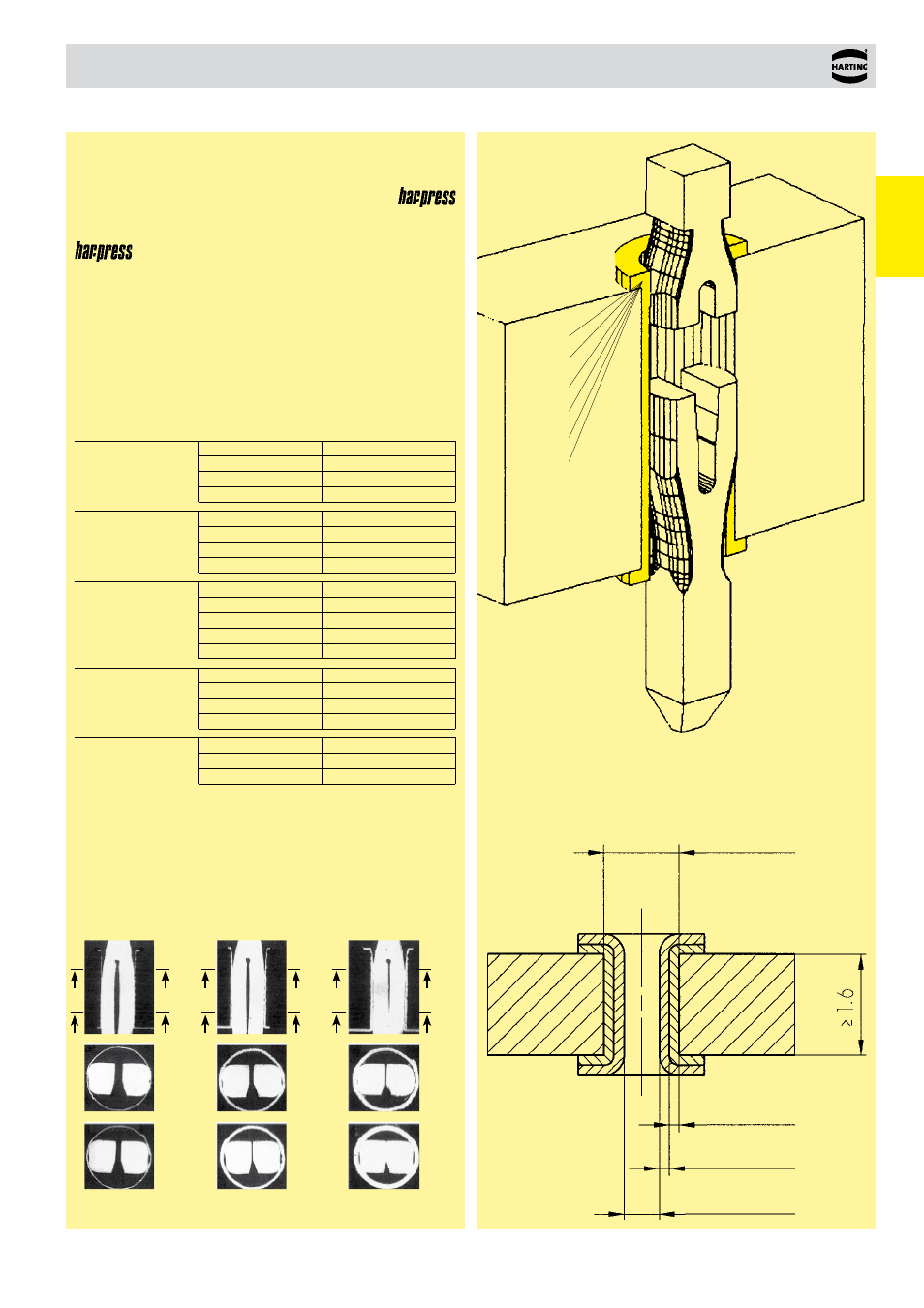

Sketch:

press-in zone

in plated through hole

pcb holes

for press-in

process in acc.

to EN 60 352-5

Sn (HAL)

chem. Sn

Au

Ag

pure Cu

Pd

Recommended configuration of plated

through holes

Due to the high deformation resistance and resilience of

contacts, they can be easily and repeatedly removed in case of

repairs without impairment to their functioning.

is extremely versatile and offers a reliable electrical

contact, therefore it is especially well suited for applications with

these surfaces.

Please contact us for detailed test reports.

In addition to the hot-air-level (HAL) other pcb

surfaces are

getting more important. Due to their different properties, such as

mechanical strength and coefficient of friction we recommend the

following configuration of pcb through holes.

Tin-lead plated

Hole-Ø 1.15

±0.025

mm

PCB

Cu

min. 25 µm

(HAL)

Sn

max. 15 µm

acc. EN 60 352-5

Plated hole-Ø

0.94-1.09 mm

Chemical

Hole-Ø 1.15

±0.025

mm

tin-plated PCB

Cu

min. 25 µm

Sn

min. 0.8 µm

Plated hole-Ø

1.00-1.10 mm

Au / Ni plated PCB

Hole-Ø 1.15

±0.025

mm

Cu

min. 25 µm

Ni

3-7 µm

Au

0.05-0.12 µm

Plated hole-Ø

1.00-1.10 mm

Silver plated PCB

Hole-Ø 1.15

±0.025

mm

Cu

min. 25 µm

Ag

0.1-0.3 µm

Plated hole-Ø

1.00-1.10 mm

OSP

Hole-Ø 1.15

±0.025

mm

copper plated PCB

Cu

min. 25 µm

Plated hole-Ø

1.00-1.10 mm

PCB board thickness: ≥ 1.6 mm

Hole-Ø

Cu

e. g. Sn

Plated hole-Ø

Terminations

Cross section of a pcb 2.4 mm thick with various hole diameters

Diameter

plated through hole

1.09 mm

(max.)

Diameter

plated through hole

0.99-1.00 mm

(nominal)

Diameter

plated through hole

0.92-0.94 mm

(min.)