Terminations – Northern Connectors Harting DIN 41 612 Connectors User Manual

Page 26

00

.

20

Gen

er

al

in

fo

rma

tio

n

Terminations

THT soldering technology

The term "soldering" is defined in DIN 8505:

"Soldering is a method of connecting metallic materials

using an additional melting metal, if necessary with the as-

sistance of a flux and/or protective gas. The melting tempe-

rature of the solder must lie beneath the minimum melting

temperature of the base metals being connected. These

base metals shall be tinned without melting themselves."

Soft solders commonly used on electronic equipment are to

DIN 1707-100. Todays lead free solders have a melting range

between 217 °C and 227 °C depending on the composition of the

alloy. For soldering metallic materials the flux is defined in DIN

EN 29 454-1. Tests are explained in DIN 8526. For soldering male

connectors into printed circuit boards, see recommendations for

soldering on page 00.06.

SMC soldering technology

The continuing trend towards miniaturisation has

revolutionised the assembly of electronic components. For the

past 15 years, most components have been secured directly

to the pcb surface by means of Surface Mount Technology

(SMT). By dispensing with drilled holes on the pcb, a space

saving of up to 70 percent is achieved.

Today, typical components such as resistors, ICs, capacitors, and

connectors with straight terminal pins are almost exclusively fitted

using SMD (Surface Mount Device) technology in mass production.

In contrast, angled SMD connectors at the edge of the board have

not been successful because of tolerance problems (co-planarity)

and stresses during mating. Modified solder connectors for

assembly with "Pin in Hole Intrusive Reflow" process offer a better

solution. These can be mounted at low cost, utilising existing SMD

production lines.

“Pin in Hole Intrusive Reflow”

In this process, the connector is inserted into plated through holes

in a comparable way to conventional component mounting. All

other components can be assembled on the pcb surface.

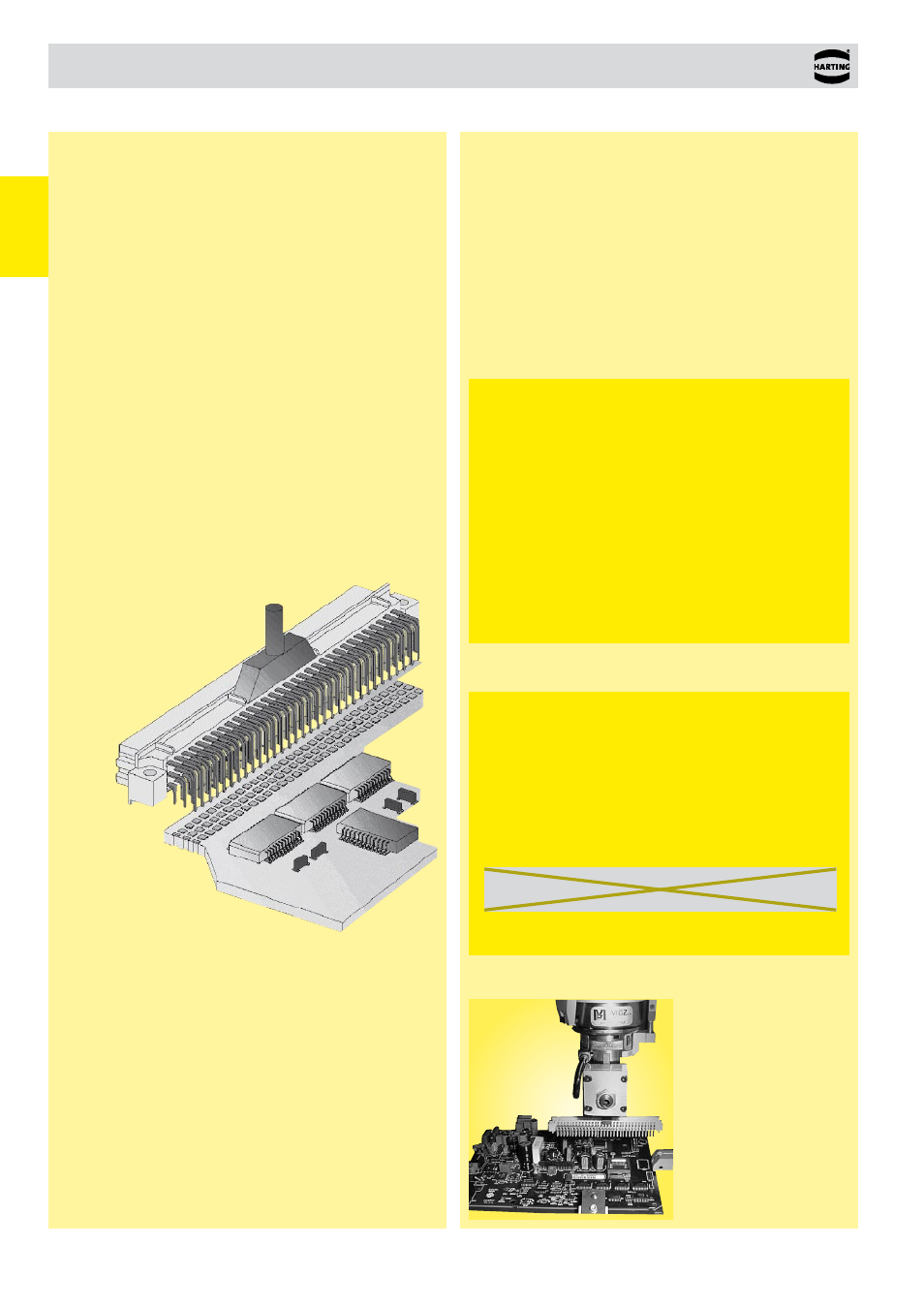

Fig. 1:

SMT board with connector for

"Pin in Hole Intrusive Reflow" assembly

Fig. 2:

Pick-and-place machine for

odd form components

(Courtesy of JOT Automation GmbH)

The components are positioned using pick-and-place machines.

These automatic assembly machines differ according to whether

the components are small, lightweight or bulky. Connectors are

considered bulky (odd form) because of their comparatively heavy

weight and large volume which makes them more difficult to grip.

Furthermore, machines for odd form components must have

higher insertion power to fit the components into pcb holes, which

are filled with solder paste. As a rule, modern SMC production

lines are equipped with both types of machine, therefore the

"Pin in Hole Intrusive Reflow" process generally entails no extra

investment costs for the user.

Conventional assembly process:

1. Application of solder paste

2. Positioning the components

3. Positioning odd form components

4. Reflow soldering

5. Pressing in or partially dip soldering the

connector at the board edge

6. Quality inspection

“Pin in Hole Intrusive Reflow” assembly:

1. Application of solder paste

2. Positioning the components

3. Positioning odd form components

4. Reflow soldering

5. Pressing in or partially dip soldering the

connector at the board edge

6. Quality inspection