Specifications, assembly instructions – Northern Connectors Harting DIN 41 612 Connectors User Manual

Page 12

00

.

06

➀ + ➂

➁

Gen

er

al

in

fo

rma

tio

n

Specifications, assembly instructions

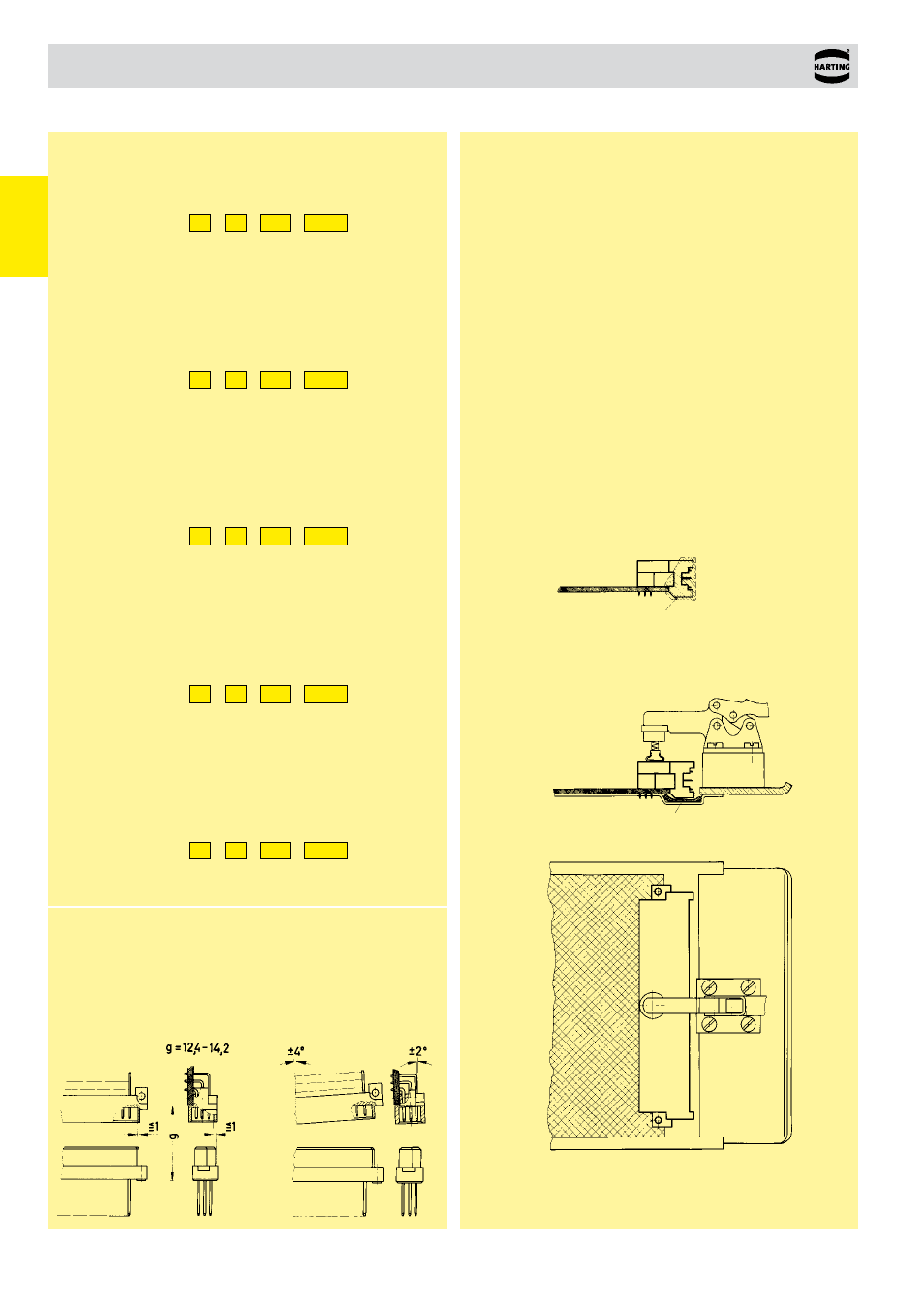

Soldering the male connectors into pcb´s

Male connectors should be protected when being soldered in a dip,

flow or film soldering baths. Otherwise, they might become contami-

nated as a result of soldering operations or deformed as a result of

overheating.

➀

For prototypes and short runs protect the connectors with an

indus

trial adhesive tape, e.g. Tesaband 4331 (www.tesa.de).

Cover the underside of the connector moulding and the adjacent

parts of the pcb as well as the open sides of the connector. This will

prevent heat and gases of the soldering apparatus from damaging

the connector. About 140 + 5 mm of the tape should suffice.

➁

For large series a jig is recommended. Its protective cover with

a fast action mechanical locking device shields the connectors

from gas and heat generated by the sol dering apparatus. As an

additional protection a foil can be used for cov ering the parts that

should not be soldered.

➂

For prototypes and short runs the protection described under

point

➀

can be replaced by a solder protection cap. This cap can

be ordered under the part no. 09 02 000 9935.

Performance level 3 as per IEC 60 603-2

50 mating cycles

then visual inspection.

No gas test.

No functional impairment.

Part No. explanation

09

. .

. . .

7 . . .

Performance level 2 as per IEC 60 603-2

400 mating cycles.

200 mating cycles

then 4 days gas test using 10 ppm SO

2

.

Measurement of contact resistance.

200 mating cycles

then visual inspection. No abrasion of the

contact finish through to the base material.

No functional impairment.

Part No. explanation

09

. .

. . .

6 . . .

Performance level 1 as per IEC 60 603-2

500 mating cycles.

250 mating cycles

then 10 days gas test using 10 ppm SO

2

.

Measurement of contact resistance.

250 mating cycles

then visual inspection. No abrasion of the

contact finish through to the base material.

No functional impairment.

Part No. explanation

09

. .

. . .

2 . . .

Performance level 2 as per IEC 61 076-4-113

250 mating cycles.

125 mating cycles

then 4 days gas test using 10 ppm SO

2

.

Measurement of contact resistance.

125 mating cycles

then visual inspection. No abrasion of the

contact finish through to the base material.

No functional impairment.

Part No. explanation

02

. .

. . .

2 . . .

Performance level 1 as per IEC 61 076-4-113

500 mating cycles.

250 mating cycles

then 10 days gas test using 10 ppm SO

2

.

Measurement of contact resistance.

250 mating cycles

then visual inspection. No abrasion of the

contact finish through to the base material.

No functional impairment.

Part No. explanation

02

. .

. . .

1 . . .

Other plating finishes available on request.

Mating conditions

To ensure reliable connections and prevent unnecessary damage,

please refer to the application data diagrams.

These recommendations are set out in IEC 60 603-2.

The connectors should not be coupled and decoupled under electrical

load.

Adhesive tape or

protection cap

Intermediate foil