Motor cable, Wiring of the standard device – Lenze EVS9332xS User Manual

Page 87

Wiring of the standard device

Notes on project planning

Motor cable

5.2

5.2.10

l

5.2−8

EDSVS9332S EN 6.0−07/2013

5.2.10

Motor cable

ƒ The used motor cables must

– meet the requirements on site (e.g. EN 60204−1, UL),

– comply with the following voltage data: EN 0.6/1 kV, UL 600 V.

ƒ For shielded motor cables, only use cables with braid made of tinned or

nickel−plated copper. Shields made of steel braid are not suitable.

– The overlap rate of the braid must be at least 70 % with an overlap

angle of 90°.

ƒ Use low−capacitance motor cables:

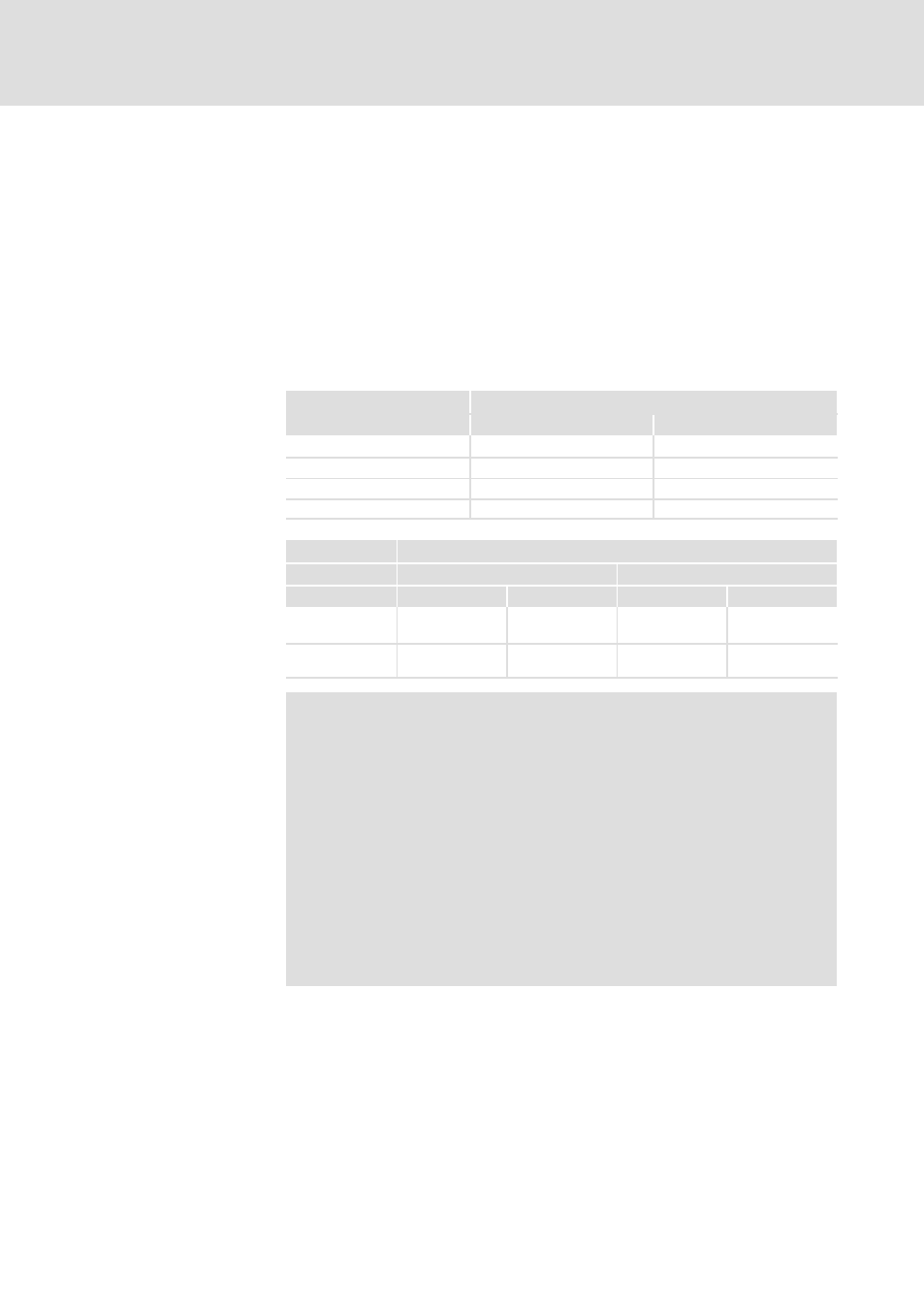

Power class

Capacitance per unit length

Core/core

Core/shield

3 ... 11 kW

from 2.5 mm

2

£100 pF/m

£ 150 pF/m

15 ... 30 kW

£ 140 pF/m

£ 230 pF/m

45 ... 55 kW

£ 190 pF/m

£ 320 pF/m

75 ... 90 kW

£ 250 pF/m

£ 410 pF/m

9300

Maximum permissible motor cable length

U

r

= 400 V

U

r

= 480 V

Type

f

chop

= 8 kHz

f

chop

= 16 kHz

f

chop

= 8 kHz

f

chop

= 16 kHz

EVS9321−xS,

EVS9322−xS

50 m

45 m

50 m

25 m

EVS9323−xS ...

EVS9332−xS

50 m

50 m

50 m

50 m

)

Note!

ƒ

The motor cable must be as short as possible for having a

positive effect on the drive behaviour.

ƒ

If EMC requirements must be met, the permissible cable

length may be affected.

ƒ

EVS9321−xSand EVS9322−xS: At a mains voltage of 480 V and

a switching frequency f

chop

= 16 kHz, the maximum

permissible cable length is reduced if the motor cable has

more than a single core:

– The following holds true for two parallel single cores:

l

max

= 17 m

– The following holds true for three parallel single cores:

l

max

= 9 m

Specification

Cable length