Earthing the drives/displacement encoders – Festo Контроллер позиционирования CPX-CMAX User Manual

Page 64

3. Electrical installation

3−4

Festo P.BE−CPX−CMA X−SYS−EN en 0908NH

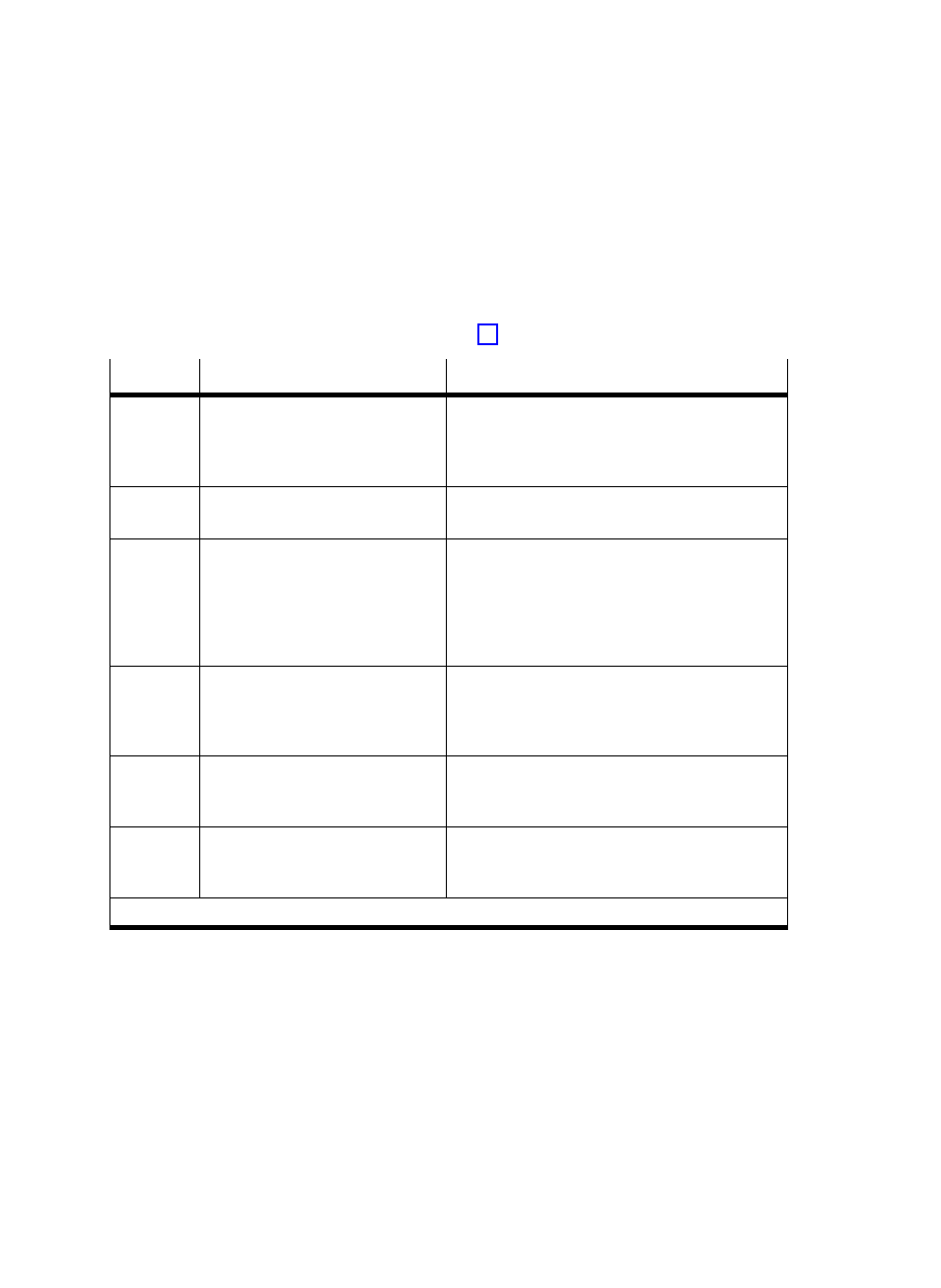

Earthing the drives/displacement encoders...

Depending on the drive or displacement encoder used, these

must be earthed. See Tab. 3/1.

Drive

Description

Earthing instructions

DGCI

Linear drive with permanently

integrated position measuring

system.

·

Make a low−impedance connection (earthing

strap) between the flat pin of the position

measuring system and the earth potential!

ć Flat pin (DIN 46246−2, width: 4.8 mm)

DGP(L)

Linear drive with external position

measuring system MLO−POT−...−TLF.

·

Mount the position measuring system so that it

is electrically isolated.

1)

DNCI

Standard cylinder with integrated

position measuring system.

·

Make a low−impedance connection (short

cable with large cross section) between the

earth terminal on the cylinder and the earth

potential.

1)

A self−tapping screw for mounting an earth strap

is supplied with the displacement encoder.

DNC

Standard cylinder with external

position measuring system

MLO−POT−...−LWG.

·

Make a low−impedance connection (earthing

strap supplied) between the flat pin of the

position measuring system and the earth

potential!

DNCM

Standard cylinder with external

position measuring system already

mounted on delivery.

No earthing is required.

DSMI

Semi−rotary drive with integrated

position measuring system.

·

Make a low−impedance connection (earthing

strap) between the earth terminal of the DSMI

and the earth potential.

1)

Alternatively: Mount the drive on an earthed machine frame.

Tab. 3/1: Instructions for earthing the drive and position measuring systems