Section 2.3 – Festo Контроллер позиционирования CPX-CMAX User Manual

Page 36

2. Fitting and pneumatic installation

2−6

Festo P.BE−CPX−CMA X−SYS−EN en 0908NH

2.3

Installation of the drive and position measuring system

Use only the drive/displacement encoder combinations

approved by Festo for the CMAX.

Note

In order to avoid damage due to uncushioned movement

into the end positions:

·

Use appropriate shock absorbers.

·

Define the software end positions.

To avoid damage to the displacement encoder when the

displacement encoder is shorter than the drive stroke:

·

Limit the travel range with additional end stops.

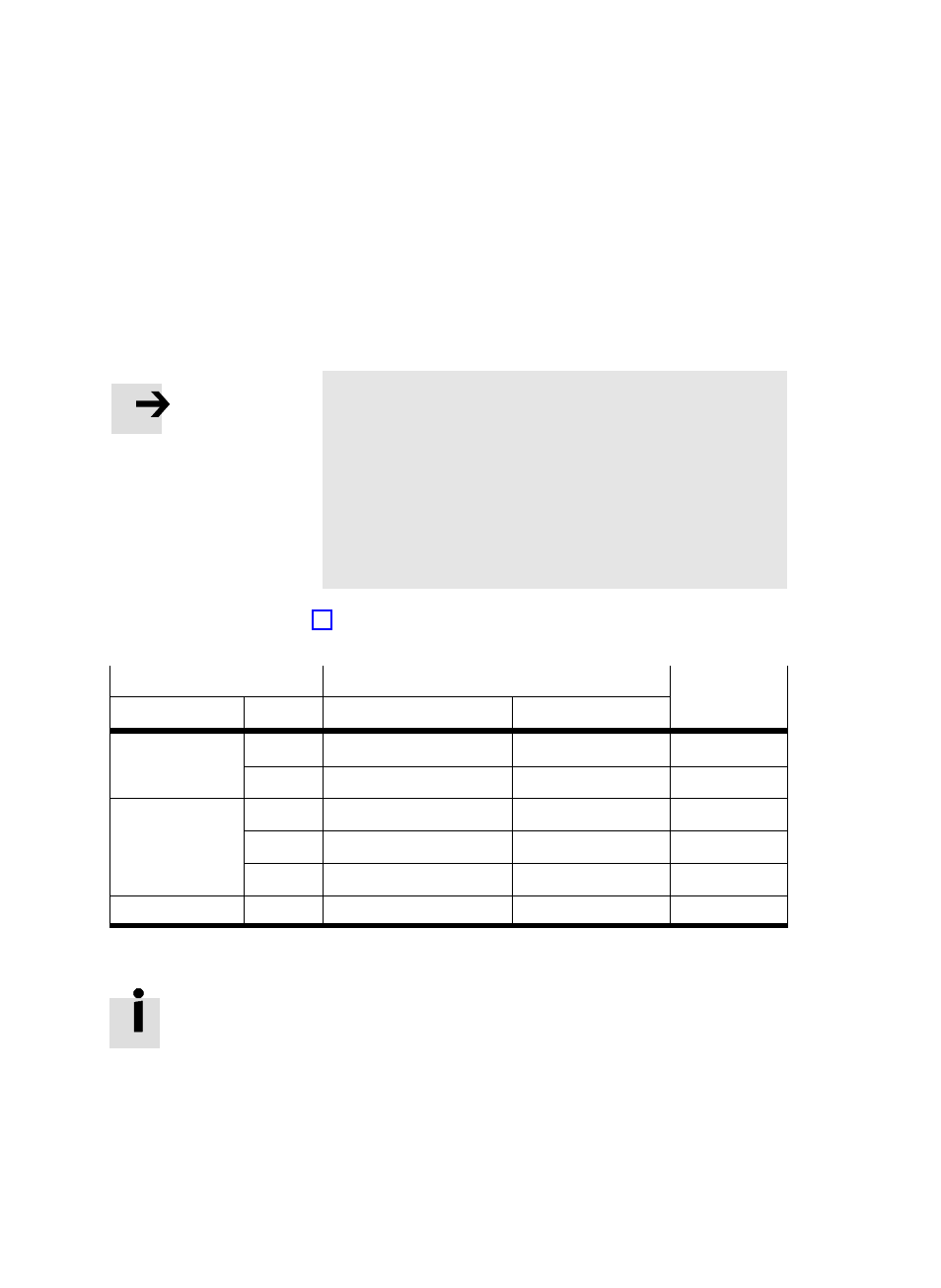

Tab. 2/1 shows the approved drive/displacement encoder

combinations:

Drive

Displacement encoder

Sensor

i t f

Design

Type

Design, function

Type

interface

Linear drive

DGCI

Digital (absolute)

Integrated

ć

DGP(L)

Potentiometer (absolute)

MLO−POT−TLF−...

CASM−S−D2−R3

Cylinder

DNCI

Encoder (incremental)

Integrated

CASM−S−D3−R7

DNC

Potentiometer (absolute)

MLO−POT−LWG−...

CASM−S−D2−R3

DNCM

Potentiometer (absolute)

Integrated

CASM−S−D2−R3

Semi−rotary drive

DSMI

Potentiometer (absolute)

Integrated

CASM−S−D2−R3

Tab. 2/1: Drive overview (as of August 2009)

Further drives are in preparation.