Festo Контроллер позиционирования CPX-CMAX User Manual

Page 131

5. Diagnostics and error handling

5−9

Festo P.BE−CPX−CMA X−SYS−EN en 0908NH

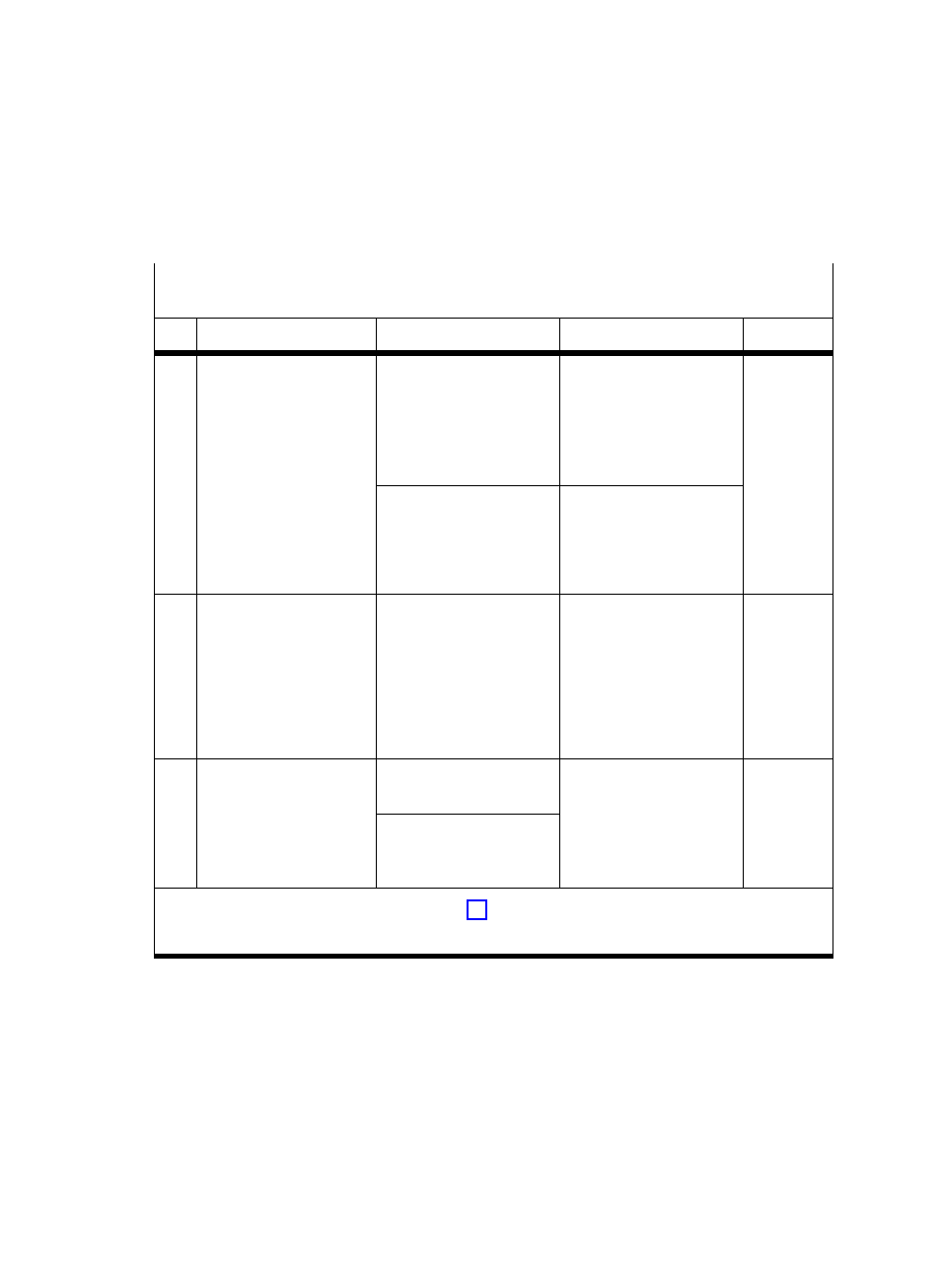

Malfunction group 0 ć Configuration error

CPX error group 100 (CPX−MMI: [Configuration error] )

Continued

No.

Message

Cause/description

Error handling

Type

1)

05

Project is not completely

loaded or block downĆ

load is still active

The controller cannot be

enabled because the

target configuration is not

yet complete. (ConfigurĆ

ation status C00, C01 or

C02).

·

Complete the target

configuration, e.g.

project download.

Error

level: F2

Reset: R

The controller cannot be

enabled because the

block download is still acĆ

tive.

·

End the block downĆ

load. If necessary,

check the PLC program

(parameterisation)

and correct.

08

Cylinder, valve or sensor

interface was replaced

2)

The serial number of a

component on the axis

string has changed:

Ĉ Drive (displacement

encoder)

Ĉ Valve

1. Accept the serial

number of the

component.

2. Carry out a movement

test (recommendaĆ

tion):

3. Carry out identification

(recommendation):

Error

level: W

Reset: F

09

Project contains incorrect

parameters

Software end positions

inconsistent.

·

Read out diagnostic

memory, determine

parameters via addiĆ

Error

level: F2

Reset: N

Invalid values for axis

parameters or hardware

configuration.

parameters via addiĆ

tional information.

·

Check the parameters

and correct.

Reset: N

1)

For the error level and reset type, see section 5.2.3.

2)

To avoid tubing errors, the movement test is reset. CMAX has the status C03. The movement test

should be executed again afterwards.