Dwyer PUX User Manual

Page 84

11- 4

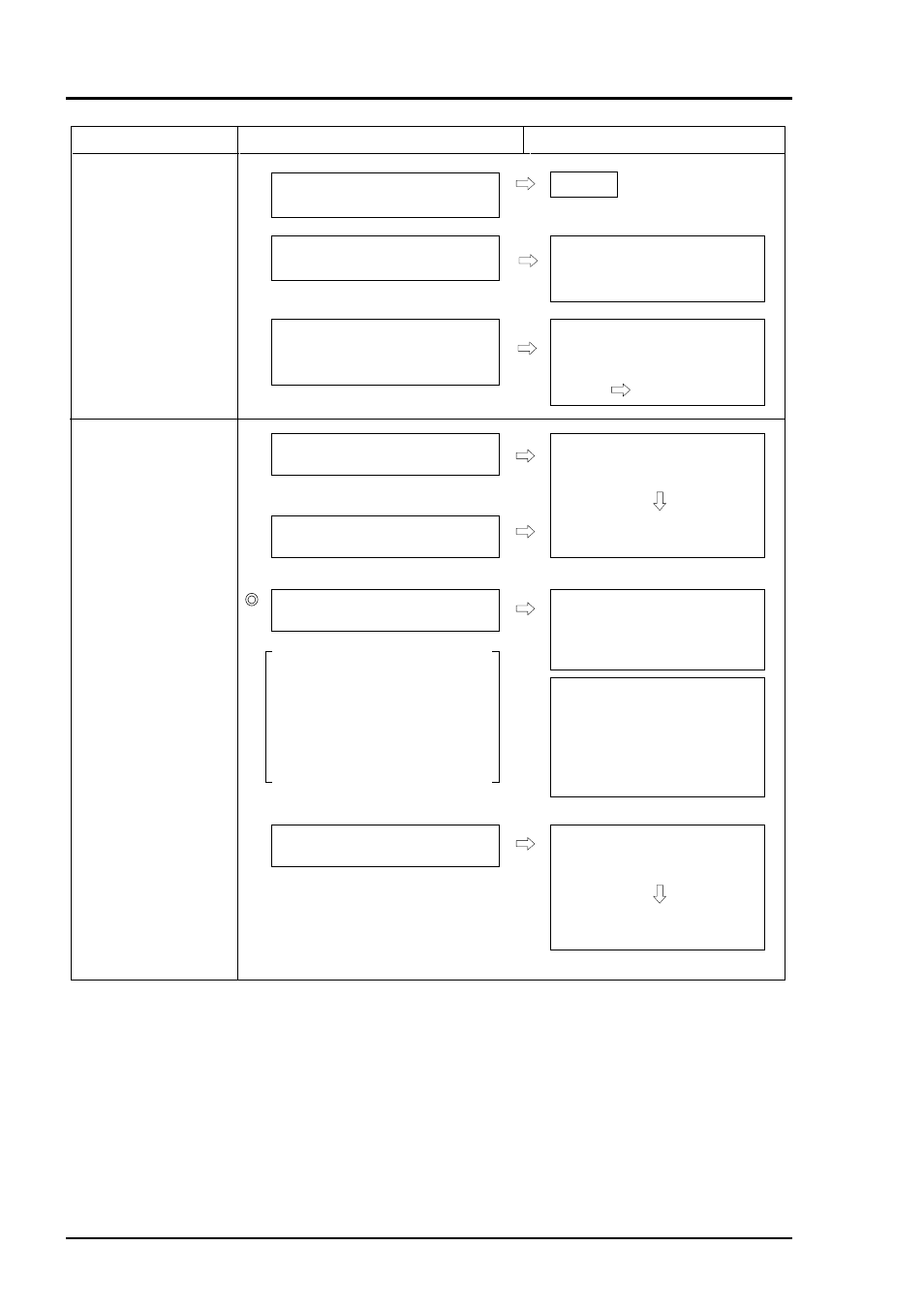

Normal

• Perform zero adjustment

again after making sure water

flow has stopped completely.

• The measured value, just

when ultrasonic wave cannot

be propagated, is held.

Normal

• A difference of 1% in inner

diameter causes an error of

about 3%.

• Input specifications correctly.

• Input scale as lining.

Select a different location of

sensor mounting (move the up-

stream side of a flow disturbing

element).

• Mount the sensor at different

angles with respect to the

cross section of pipe to find

the location where mean value

is obtainable. The mount the

sensor at that location.

Precipitation is more when the

cross section of pipe has a

smaller area.

Shift the sensor to the vertical

portion of pipe.

Measured value is not

zero though water flow

has stopped.

•

Water is subjected to convection in

a pipe.

•

Zero adjustment has been

performed.

•

When water flow stops, pipe is not

filled up with water or becomes

empty.

•

Input piping specifications are

different from actual ones.

•

Because of an old pipe, scale has

stuck.

The length of straight pipe portion

is inadequate.

10D and 5D are required at least

on the upstream and downstream

sides.

Flow disturbing element should

not be present within 30D on

upstream side.

Pump, valve, flow joining pipe or

the like is unallowable.

•

Pipe is not filled with water or

mud and sand have precipitated.

Measured value has an

error.

State

Cause

Remedy

BULLETIN F-68