Bulletin f-68, Countermeasures against error screen – Dwyer PUX User Manual

Page 75

9 - 34

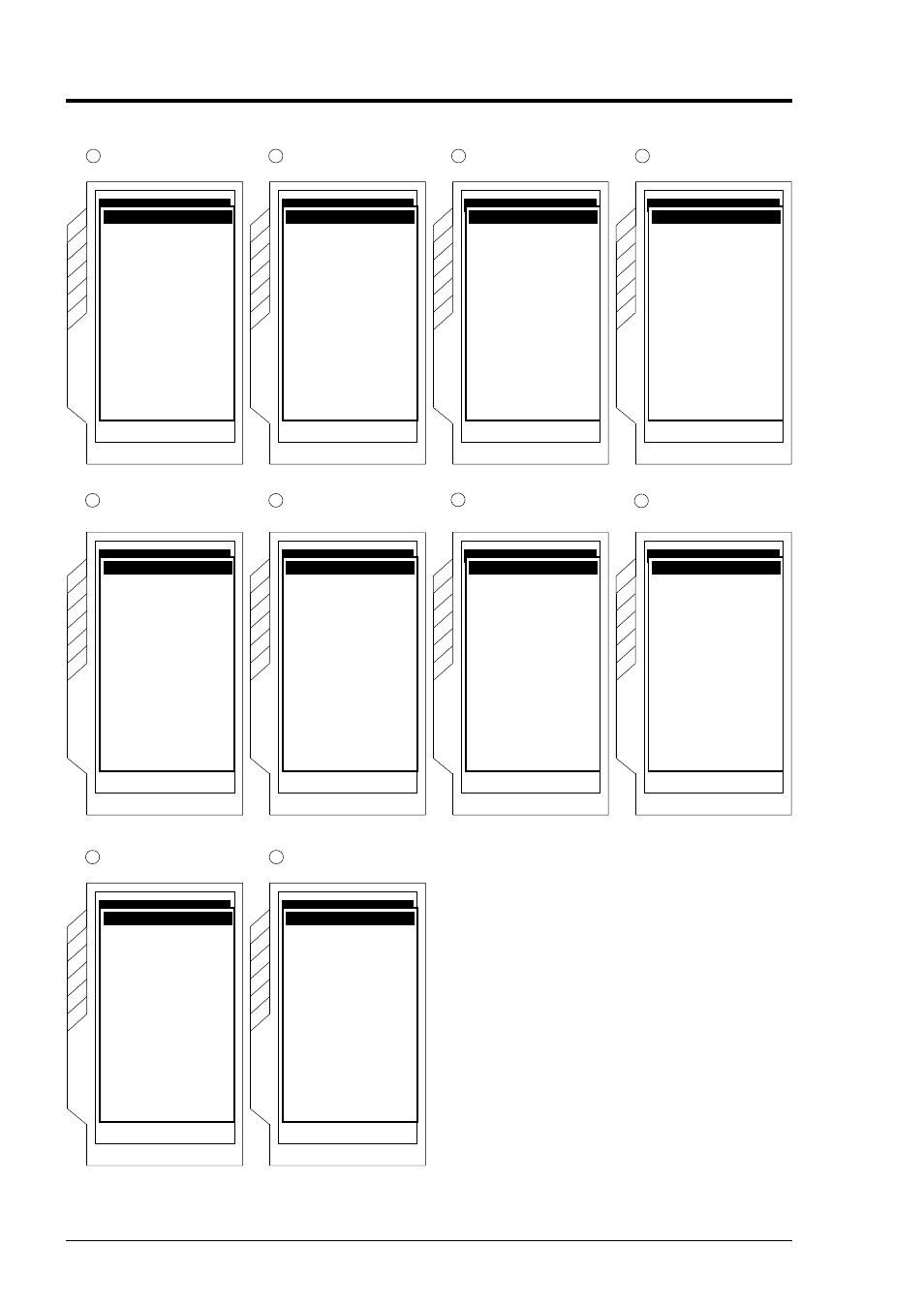

Countermeasures against error screen

SYSTEM CHECK

SYSTEM CHECK

SYSTEM CHECK

SYSTEM CHECK

SYSTEM CHECK

SYSTEM CHECK

SYSTEM CHECK

SYSTEM CHECK

SYSTEM CHECK

SYSTEM CHECK

SYSTEM CHECK

SYSTEM CHECK

SYSTEM CHECK

SYSTEM CHECK

SYSTEM CHECK

SYSTEM CHECK

SYSTEM CHECK

SYSTEM CHECK

SYSTEM CHECK

SYSTEM CHECK

BACKUP BATTERY FAIL

Backup battery for set data

and logging data has failed.

Contact the factory for ex-

change!

Be careful that the data

will fail if you turn the

power off!

Be careful that this fail

information will disappear

if you press the ESC key!

ANALOG OUTPUT ERROR

BACKUP BATTERY FAIL

ANALOG OUTPUT ERROR

Magnitude of analog output

exceeds the scale range.

Change the scale!

RECEIVED SIGNAL ERROR

The strength of received

signals is changing so fre-

quently that measurements

are impossible!

Check if many bubbles or

solid particles are contain-

ed in measured fluid!

If so,reduce them to be

measurable,otherwise change

the mounting site of the

detector to other places.

WINDOW SCANNIG

There is no signal within

the measuring window.

Therefore the measuring

window is being scanned

to search signal wave.

NO RECEIVED SIGNAL

Received signals are so

poor that measurements are

impossible.

Recheck the set data,espe-

cially pipe parameters and

sensor mounting method!

Check the sensor spacing,

and the connection betwween

converter and detector!

Otherwise set the trans-

mission voltage higher.

TOO STRONG RECEIVED SIGNAL

RECEIVED SIGNAL ERROR

WINDOW SCANNI

N

NO RECEIVED SIGNAL

TOO STRONG RECEIVED

SIGNAL

Received signals are so

strong that measurments are

impossible.

Change the mounting method

of the detector from Z to V!

INSIDE COMMUNICATION FAIL

INSIDE COMMUNICATION FAIL

Inside communication be-

tween modules has failed, so

measurements are impossible.

Turn the power off and on!

When the function will not

recover,contact the factory

MEASURING MODULE FAULT

MEASURING MODULE FAULT

Measuring has not acted

correctly.

Turn the power off and on!

When the function will not

recover,contact the factory.

CALCULATION ERROR

CALCULATION ERROR

Calculated parameters for

flowrate measurement are not

correct.

Recheck the set data!

Turn the power off and on!

When the function will not

recover,contact the factory.

PRINTER FAIL

PRINTER FAIL

Printer unit has failed,so

it cannot start printing.

Check whether paper jam or

not!

Check if the connection to

the converter is correct.

Turn the power switches of

converter and printer unit

off and on!

When the function will not

recover,contact the factory.

1

2

3

4

5

6

9

10

7

8

BULLETIN F-68