Sensor to pipe - 5, Caution – Dwyer PUX User Manual

Page 34

7 - 5

7.4

How to mount small size (standard) sensor and small

outer diameter sensor to pipe

q

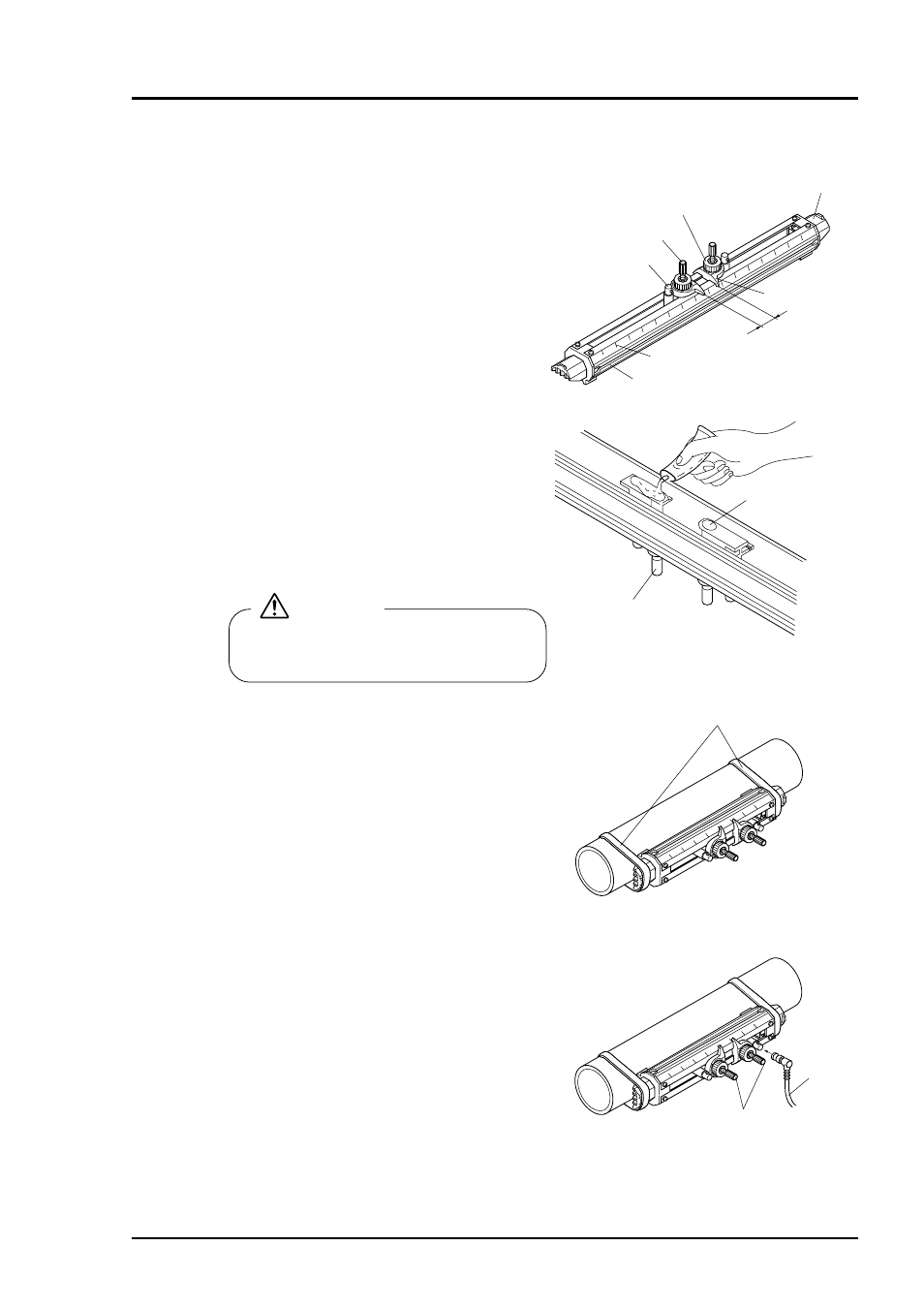

Loosen the lock nut and slide the sensor so as to

meet the mounting dimension and then tighten

the nut.

w

Apply a coat of silicone grease to the

transmitting surface of the sensor. Spread the

compound over the entire area.

Keep the sensor retracted by turning the element

holder counterclockwise.

After cleaning the surface of the pipe, the sensor

should be mounted.

e

Fix the both ends (saddles) of the sensor to the

pipe by cloth belts.

Mounting will be facilitated by winding the cloth

belts on the pipe in advance.

Cloth belts are usable at 80

°

C or lower. If

beyond 80

°

C, stainless steel belts should be

used.

(

)

r

Make sure the sensor is mounted in parallel with

the pipe axis and the mounting dimension is

right. Then, turn the element holder clockwise

until the sensor comes in close contact with the

pipe.

Stop turning the element holder when it stiffens

because the transmitting surface comes in

contact with the pipe surface. Be careful not to

turn the holder excessively.

CAUTION

Element holdder

Lock nut

Saddle

Scale

Cursor

Mounting

dimension (L)

Frame

BNC connector

Transmitter unit

Element holder

Cloth belt

Element holder

Cable

Apply a small quantity (like toothpaste) of

silicon grease to the transmitter unit.

BULLETIN F-68