3 error in measured value – Dwyer PUX User Manual

Page 82

11- 2

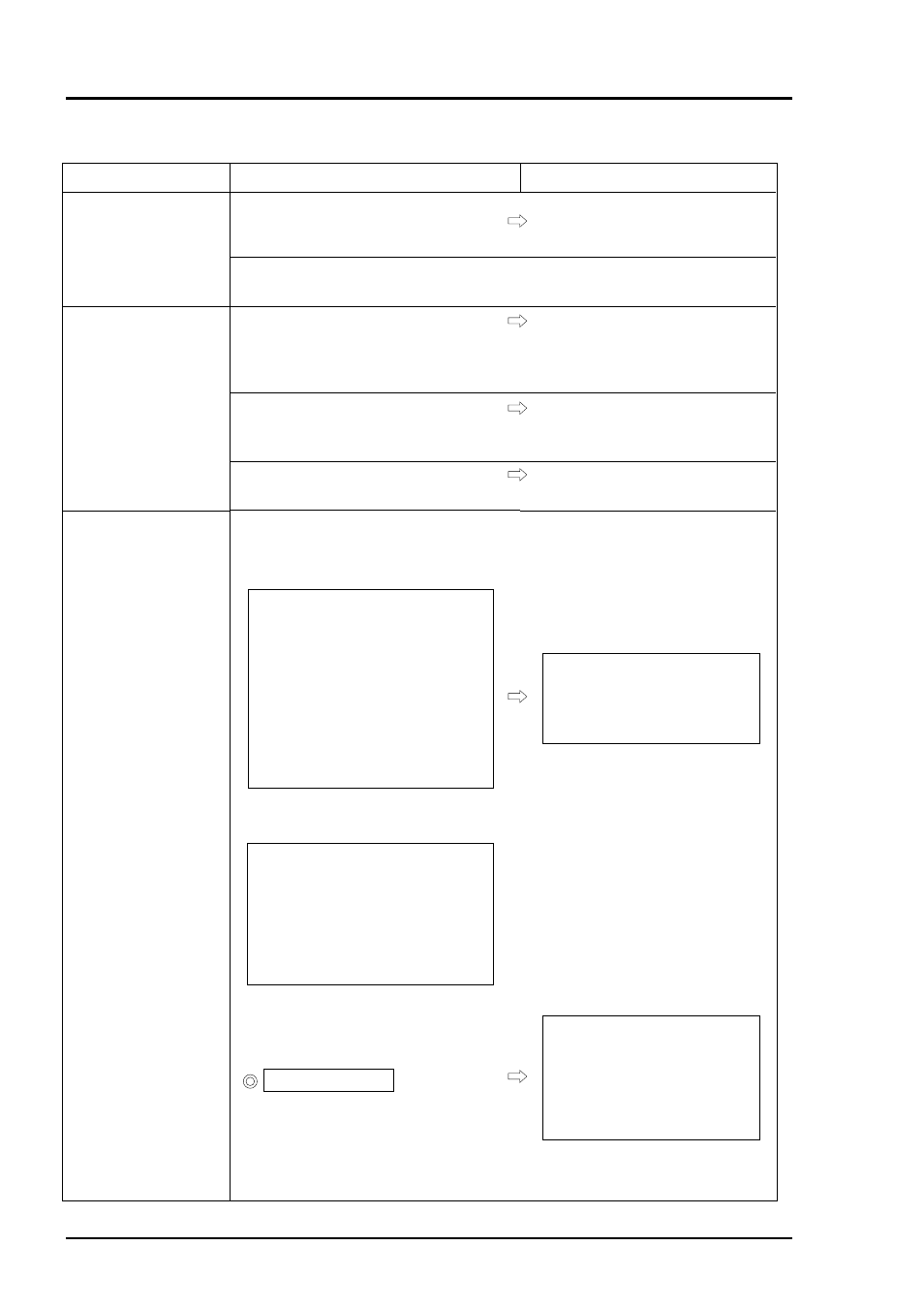

State

Cause

Indication of measured

value is negative (-).

Measured value

fluctuated widely

though flow rate is

constant.

Measured value

remains the same

though flow rate is

changing.

Connect correctly.

Shift measurement location to

the site where 10D and 5D can

be secured on the upstream and

downstream sides.

Mount the instrument with a

clearance of 30D or more.

Extend response time through

damping setting.

11.3 Error in measured value

Remedy

• Connection between the main unit

and sensors (upstream sensor and

downstream sensor) is reverse.

• Fluid is actually flowing in the (-)

direction.

• Straight pipe portion is inadequate.

• A flow disturbing factor such as

pump or valve is provided in the

vicinity.

• Pulsation is occurring actually.

• Measured value is held because ultrasonic

wave cannot be propagated into a pipe.

1. Incomplete installation

• Piping specifications are wrong.

• Sensor is mounted at the welded

part.

• Sensor mounting dimension is

wrong.

• Grease application at sensor

mounting is incomplete.

• Sensor connector is not

connected completely.

• Pipe surface is contaminated.

2. Problem on pipe or fluid

• When V method is used, it should

be changed to Z method.

• When sensor extension cable is

used, it should be avoided.

• If error persists, check and

eliminate the true cause as

instructed below.

Fluid is not filled.

After check, separate the sensor

once. Apply the grease again

and remount the sensor with a

slight shift.

Find the location on the same

pipe line, where fluid is filled

up and move the sensors to that

location.

Mount the sensors at the lowest

location on pipe line.

BULLETIN F-68