Lincoln Electric IM8002 POWER WAVE MANAGER User Manual

Page 99

Training Profiles

Chapter 11. Training

IM8002

Power Wave® Manager User Manual

11.5

When a Weld Profile has one or more training files associated with it, the gray icon ( ) next to the Weld

Profile number appears as a star icon ( ). Click the plus icon ( ) to expand the Weld Profile and view

the training files created. The training files use the date and time naming convention and are stored in the

folder selected under the Preferences button (page 4.1). See page 11.7 for details on viewing the limits

calculated for the Weld Profile and for the individual training files.

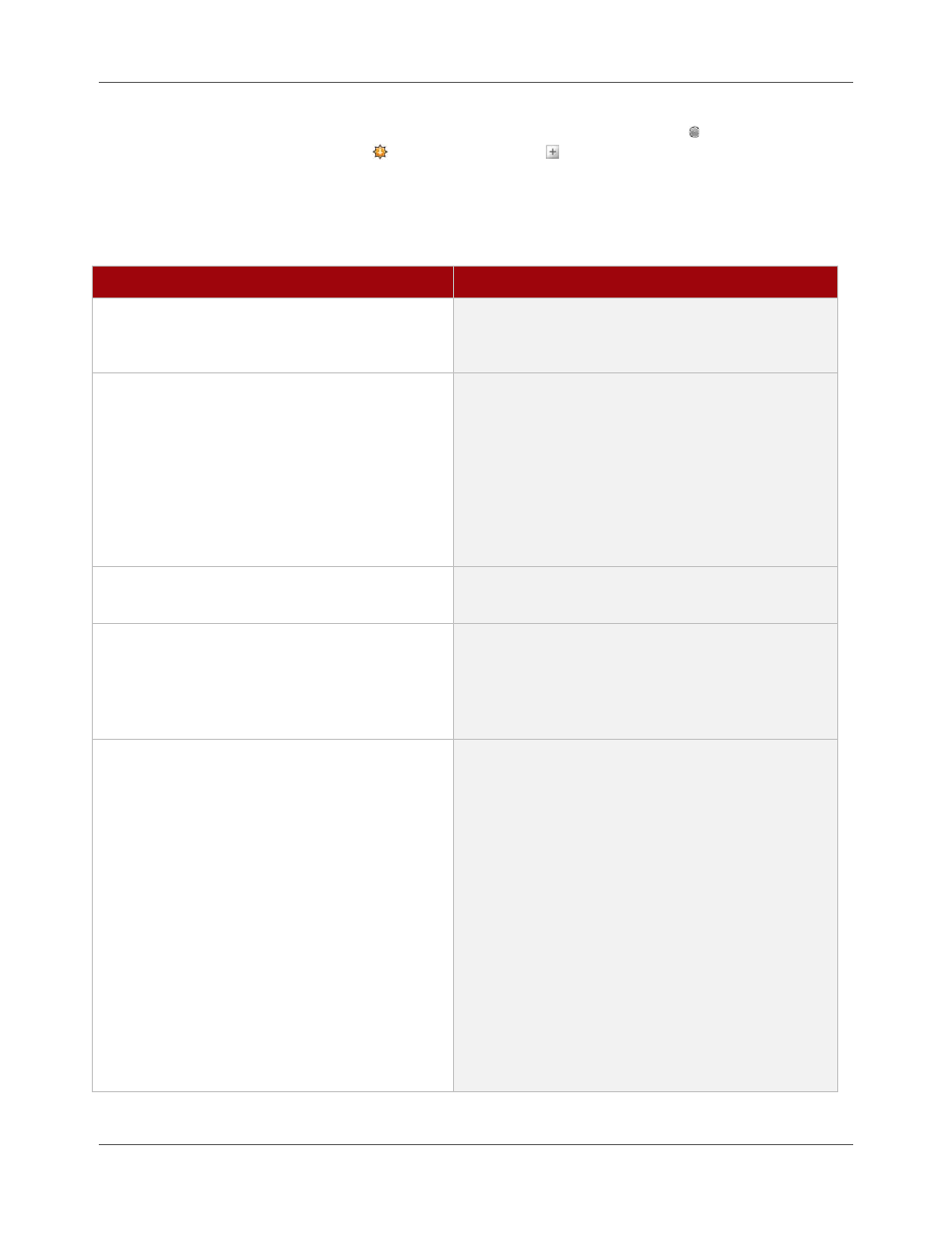

To train a Weld Profile:

Procedure

Details

1.

Click Production Monitoring > Training

in the navigation tree of Power Wave®

Manager.

The Training section opens (Figure 11.1).

2.

Click the Start training button at the top of

the window.

The system goes into Training Mode and does not

record new weld history. This helps maintain

production data integrity for the Production

Monitoring™ and CheckPoint™ software

applications.

NOTE |

The system clears any unsaved weld

history data from the Production Monitoring™

server computer or the CheckPoint™ data center.

3.

Click Yes to send the power source into

Training Mode.

The top of the window now displays the text:

Waiting for next weld to start.

4.

Select the Weld Profile you want to train by

using the method chosen for this Welding

Power Source on the Weld Profile selection

tab under Production Monitoring >

Configuration.

See page 10.4 for details on the Weld Profile

selection tab.

5.

Physically make all the welds necessary to

set the accepted values for this Weld Profile

(typically between three to five welds).

If you have short welds to train, you can train them

in succession with a short pause in between. If,

however, you have long welds to train, train them

one at a time and verify the data has transferred

before beginning the next training weld.

NOTE |

After you complete a training weld, the

computer must read the data from the Welding

Power Source. If you start a new weld before

Power Wave® Manager reads this data, the new

weld may not be recorded.

In general, it takes about one second to read data

from every 63 seconds of welding. This means a

very long training weld lasting 21 minutes could

take up to 20 seconds to be transfer to the

computer.