Lincoln Electric IM8002 POWER WAVE MANAGER User Manual

Page 87

Configuration

Chapter 10. Production Monitoring

IM8002

Power Wave® Manager User Manual

10.9

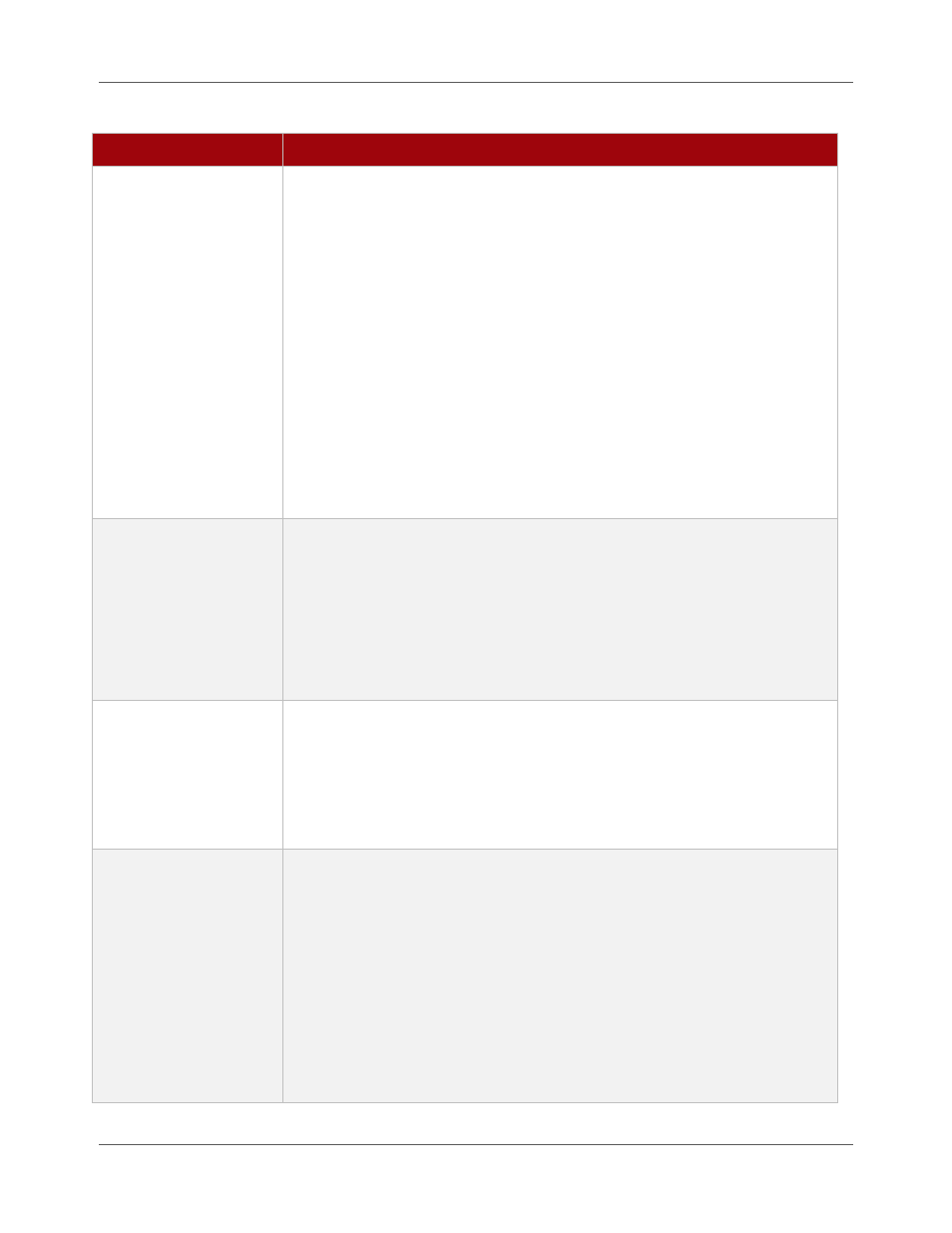

Table 10.3 Limits Available for Each Weld Profile

Field

Description

Start delay

This is the amount of delay the power source should use when applying

limits at the beginning of this weld. The Start delay is the amount of time (in

seconds) that the power source should wait, directly after the start of a weld,

before it begins to apply the limits entered for this Weld Profile. This option

is necessary because the start of a weld is often unpredictable and may fall

out of limits easily. (The Start delay must be within the range of 0.1 seconds

to 10.0 seconds.)

NOTE |

The combined Start delay and End delay times must be 0.7

seconds or greater if the Production Monitoring firmware on the power

source is at revision 4. If the total is less than 0.7, Power Wave® Manager

automatically adjusts the Start delay value so the total equals 0.7 seconds.

If the Production Monitoring firmware revision is 5 or greater, the

combined Start delay and End delay times must be 0.4 or greater. If the

total is less than 0.4, Power Wave® Manager automatically adjusts the

Start delay value accordingly.

End delay

This is the amount of delay the power source should use when applying

limits at the end of this weld. The End delay is the amount of time (in

seconds) directly before the end of a weld that the power source should

stop applying the limits entered for this Weld Profile. This option is

necessary because, at the end of a weld, the set points for the Welding

Power Source are often different than the rest of the weld (e.g., if the power

source is in a burn-back state). The End delay must be within the range of

0.1 seconds to 10.0 seconds.

Discard welds shorter

than “n” seconds

(where “n” is the Start

delay time plus the End

delay time)

Place a check mark next to this option to tell Production Monitoring™ or

CheckPoint™ that it should not record welds where the duration of the weld

is shorter than the combined Start delay and End delay times.

If this option is unchecked, welds that are greater than 0.4 seconds but less

than the Start plus End delay time will be recorded but will be marked as a

Short Weld.

Minimum WeldScore

Every quarter of a second, the Welding Power Source compares the

performance of the current weld against the trained weld for the selected

Weld Profile. When the weld is complete, the power source averages those

measurements together for an overall WeldScore™.

The Minimum WeldScore field allows you to enable the action you selected

for WeldScore™ on the Out-of-limit actions tab (page 10.5). If the overall

WeldScore™ for the weld falls below the value you enter here, the system

performs the action you selected in the Action on WeldScore limit drop-down

on the Out-of-limit actions tab.

Even if you do not have the alerts enabled, the power source still calculates

WeldScore™ on machines that support this value (if a training model exists